Automatic steel wire threading device

An automatic threading and steel wire technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems that the steel wire cannot be threaded in place, the steel wire cannot be fully tightened, and the pressure wheel is easy to loosen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

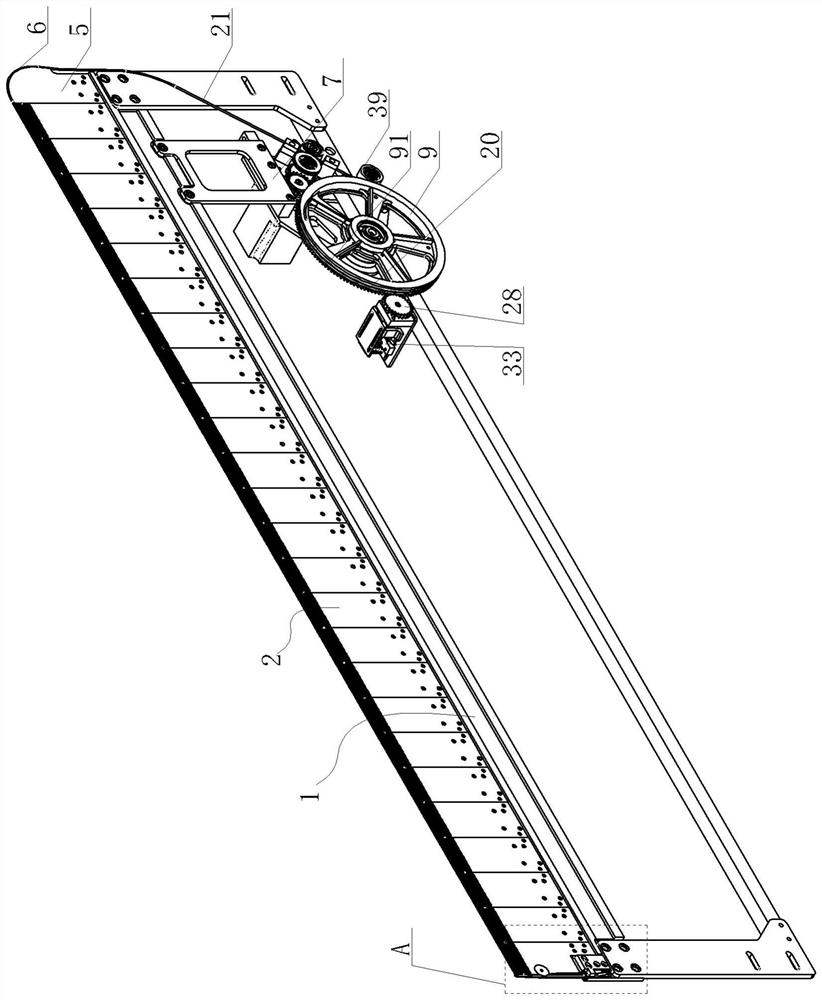

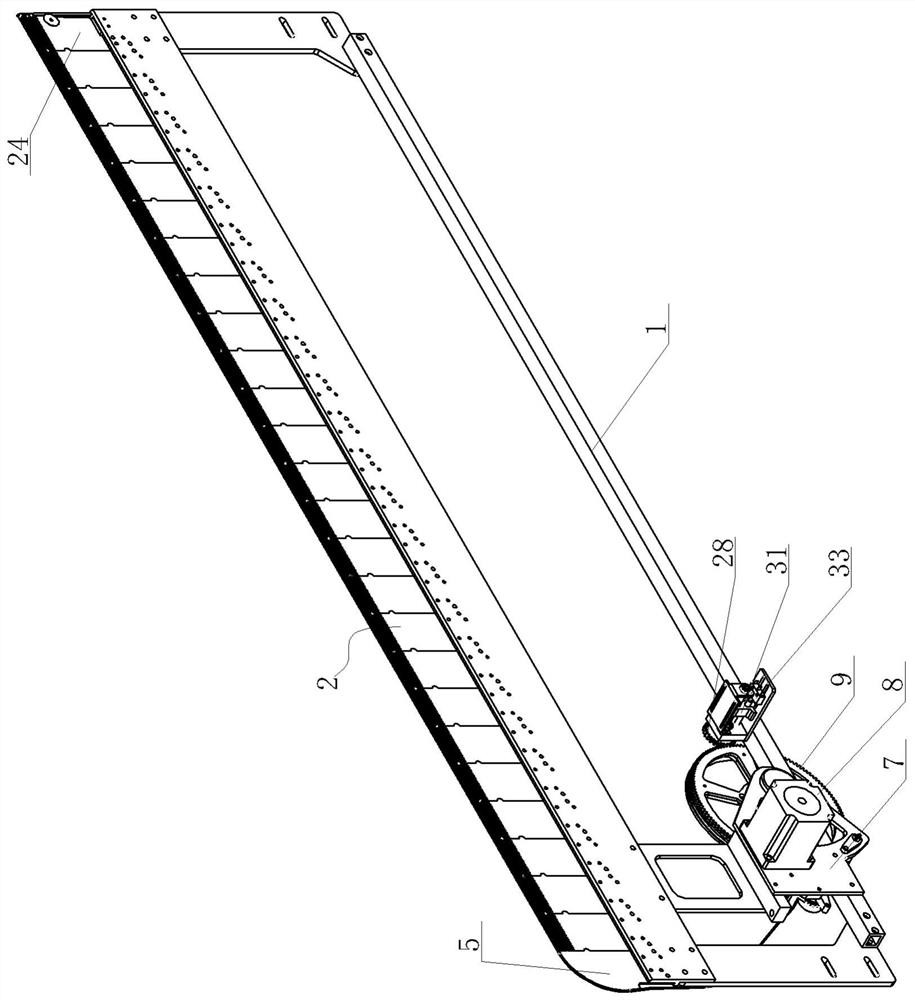

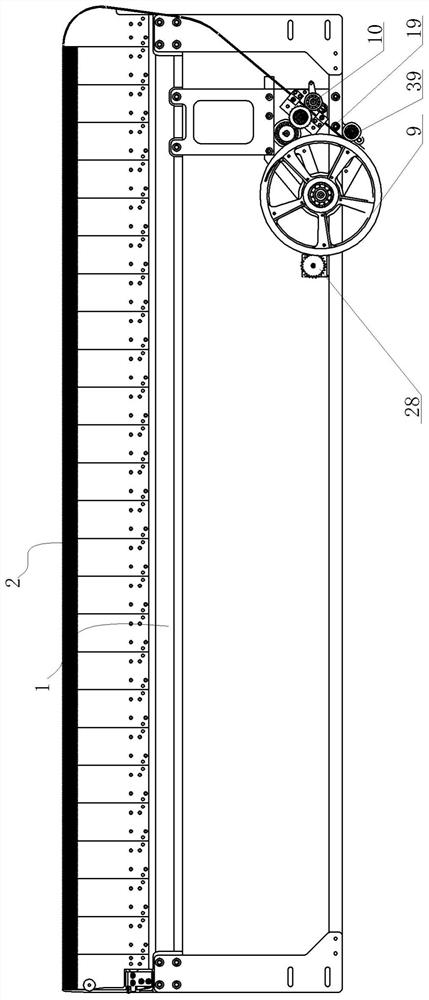

[0023] Automatic wire threading device, see Figure 1-Figure 9 : it comprises a frame 1, a group of threading plates 2 are arranged on the upper beam of the frame 1, threading needles 3 of the threading plate 2 are provided with through threading holes 4, and the threading holes 4 of all threading needles 3 The holes 4 are arranged in a straight line, and one side of the upper cross beam of the frame 1 is provided with a guiding wire threading plate 5, and the outer periphery of the guiding threading plate 5 is provided with a guiding line 6, and the frame 1 corresponds to the guiding threading plate 5. The lower area is provided with a driving mounting frame 7, and the driving mounting frame 7 is provided with a driving motor 8, a take-up wheel 9, and a line pressing roller 10. The output end of the driving motor 8 is connected with a transmission shaft 11, and the transmission shaft 11 is set with The first one-way bearing 12, the second one-way bearing 13, the active rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com