Method for preparing whey protein gel

A technology of whey protein gel and whey protein, which is applied in the field of low-acid preparation of whey protein gel, and can solve the problems of unfavorable heat sterilization and gel voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

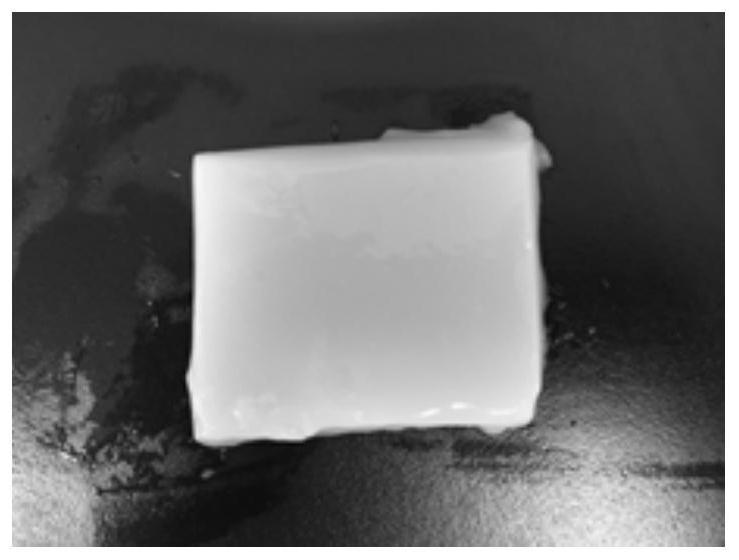

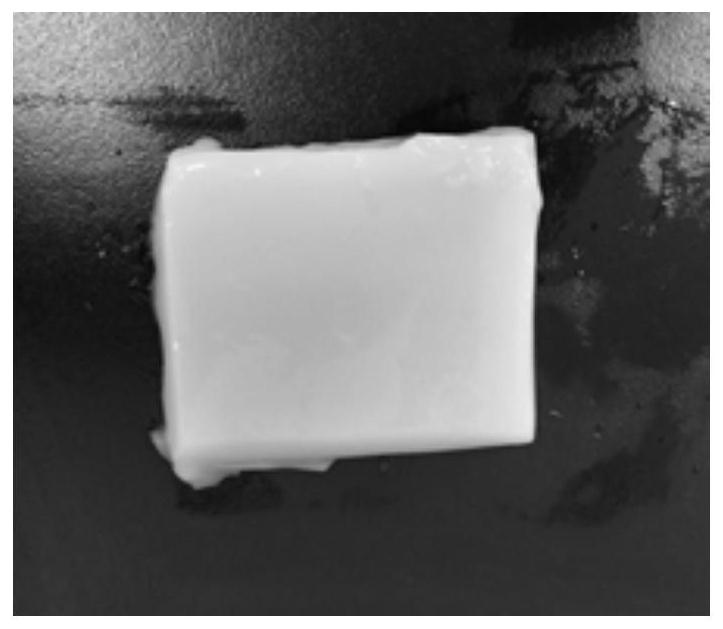

Image

Examples

Embodiment 1

[0027] Preparation

[0028] (1) Simply use water or dissolve citric acid in water to make 0, 0.15% and 0.3% citric acid aqueous solution; (2) add 8% refined whey protein powder (FONTERRA, New Zealand); (3) Add 0,0.25% and 0.5% sodium citrate, 0,0.25% and 0.5% potassium citrate and 0,0.25% and 0.5% sodium bicarbonate to the mixture of (2) (4) The mixed whey protein solution of the above (3) is subjected to commercial sterilization (121°C, 10 minutes), and the whey protein gel is formed after cooling.

[0029] Gel Strength Determination

[0030] Refer to international standards (ISO / GMIA; P / 0.5&HDP / BJB), use standard probe P / 0.5, press down at a speed of 1mm / sec, and press down to a maximum force of 4mm.

[0031] Hardness determination

[0032] With reference to the method of Cui et al. (Cui Xuhai et al., Chinese Agricultural Sciences, 41(3):803-807, 2008), using probe P / 0.5, pre-test speed: 5mm / sec, test speed: 1mm / sec, after test Speed: 10mm / sec, press down to the force (5...

Embodiment 2

[0041] The composition of the following Table 2 repeats the steps and measurements of Example 1. Table 2 lists the measurement results at the same time.

[0042] Table 2

[0043]

Embodiment 3

[0045] The composition of the following Table 3 repeats the steps and measurements of Example 1. Table 3 lists the measurement results at the same time.

[0046] table 3

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com