Main shaft of numerical control machine tool and main shaft box thereof

A technology of CNC machine tools and spindle boxes, applied in the field of CNC machine tools, can solve problems such as poor convenience and inability to realize independent feeding of tools, and achieve the effects of avoiding jamming, realizing non-stop switching, and ensuring efficient oil injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

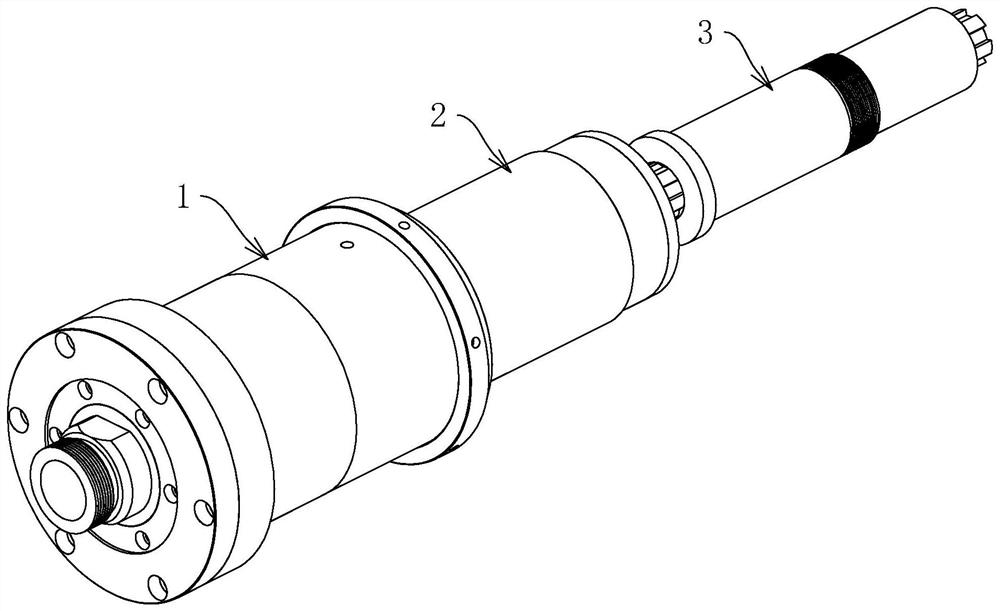

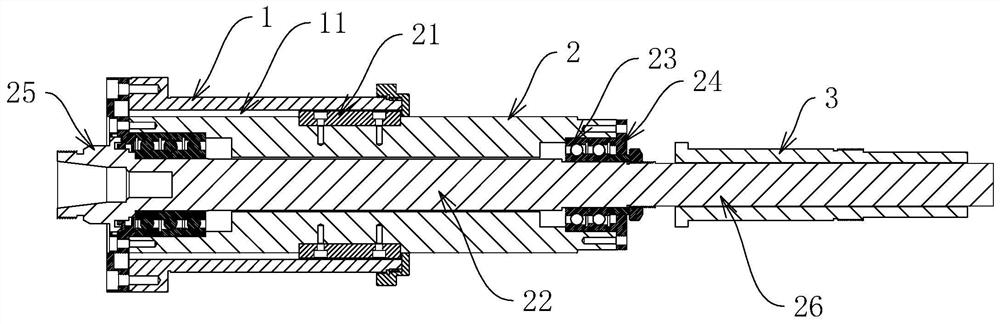

[0044] like figure 1 , figure 2 As shown, a spindle of a CNC machine tool includes a horizontally arranged shaft sleeve 1, and a mounting shaft 2 is horizontally slidably connected in the shaft sleeve 1. Both outer walls of the mounting shaft 2 are provided with guide blocks 21 horizontally, and both inner walls of the shaft sleeve 1 are provided with guide grooves 11 for horizontal sliding of the guide blocks 21 .

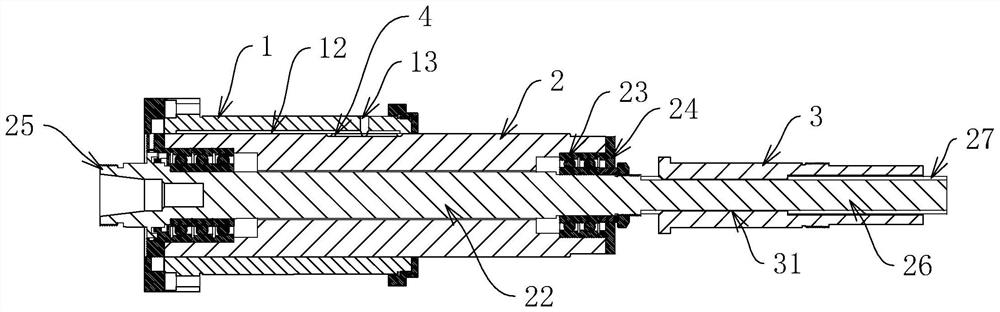

[0045] like figure 2 , image 3 As shown, a mandrel 22 is horizontally rotatably connected in the mounting shaft 2 , and a sealed bearing 23 and an end cover 24 covering the sealed bearing 23 are provided between the mandrel 22 and both ends of the mounting shaft 2 .

[0046] like figure 2 , image 3 As shown, one end of the mandrel 22 outside the installation shaft 2 is provided with a tool seat 25 for fixing the tool, and the other end outside the installation shaft 2 is extended with a sliding shaft 26 .

[0047] like figure 2 , image 3 As shown, t...

Embodiment 2

[0060] like Figure 5 As shown, a headstock of a CNC machine tool is used for installing the above-mentioned main shaft, and it comprises a base 5, and the base 5 is vertically and side by side provided with a front main board 6 and a rear main board 7, and the surrounding of the front main board 6 and the rear main board 7 Connecting ribs 51 are provided at all positions.

[0061] like Figure 5 , Image 6 As shown, a plurality of rows of front mounting hole groups 61 are arranged through the front main board 6 , and each row of front mounting hole groups 61 includes a plurality of front holes 62 arranged at intervals. The plurality of front holes 62 on the adjacent two rows of front mounting hole groups 61 are arranged in a staggered manner, and each front hole 62 is used for the shaft sleeve 1 (see figure 1 ) is embedded and fixed, and the shaft sleeve 1 is provided with a first retaining ring 14 fixed on the outer wall of the front main board 6 .

[0062] like Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com