Flywheel shell casting mould used for engine casting

A technology for casting molds and flywheel shells, which is applied in the field of casting molds for flywheel shells, can solve the problems of unfavorable and rapid disassembly of injection molding parts, insufficient functions of disassembling casting parts, and lack of selective cooling, and achieves convenient and flexible demoulding and good demoulding effect. , the effect of casting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

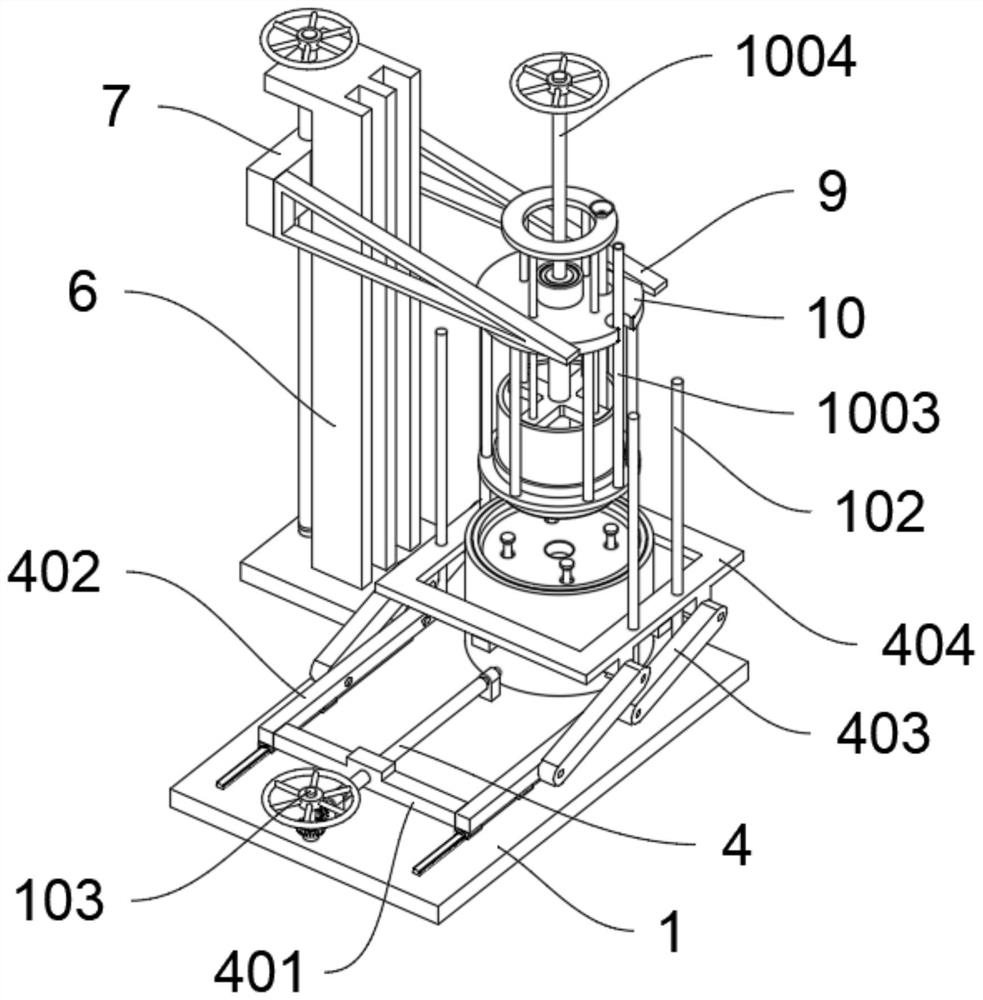

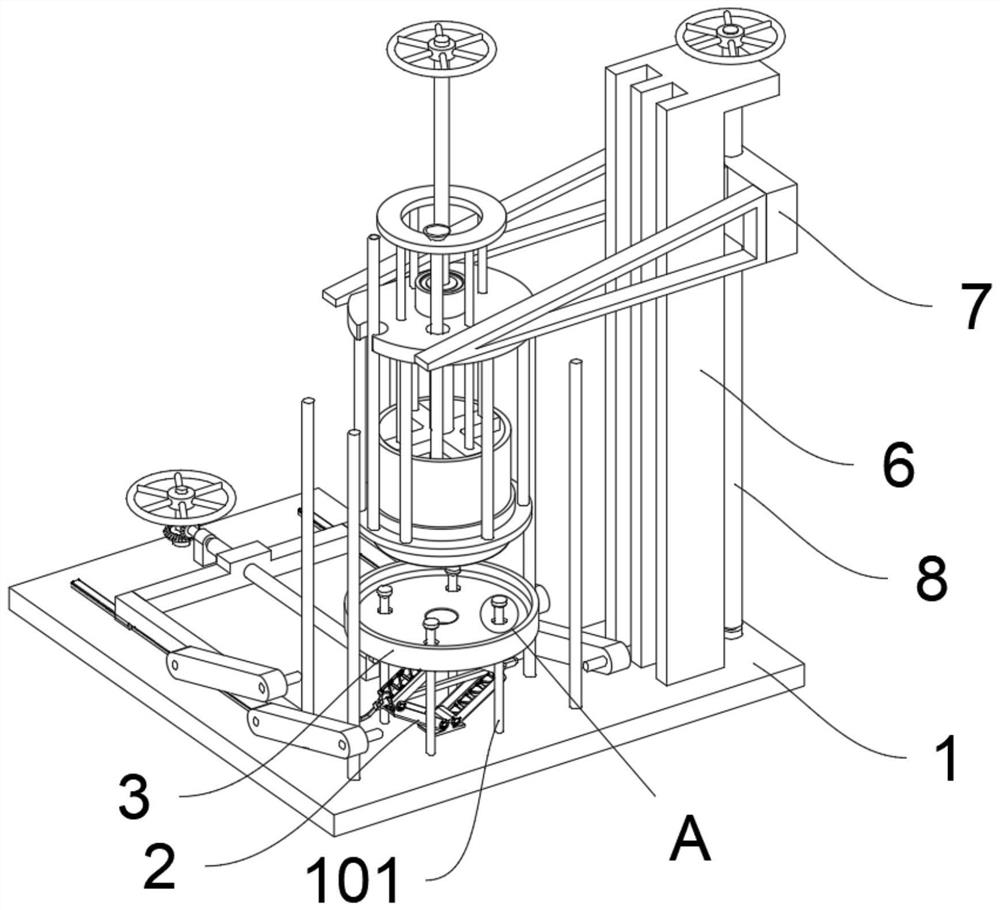

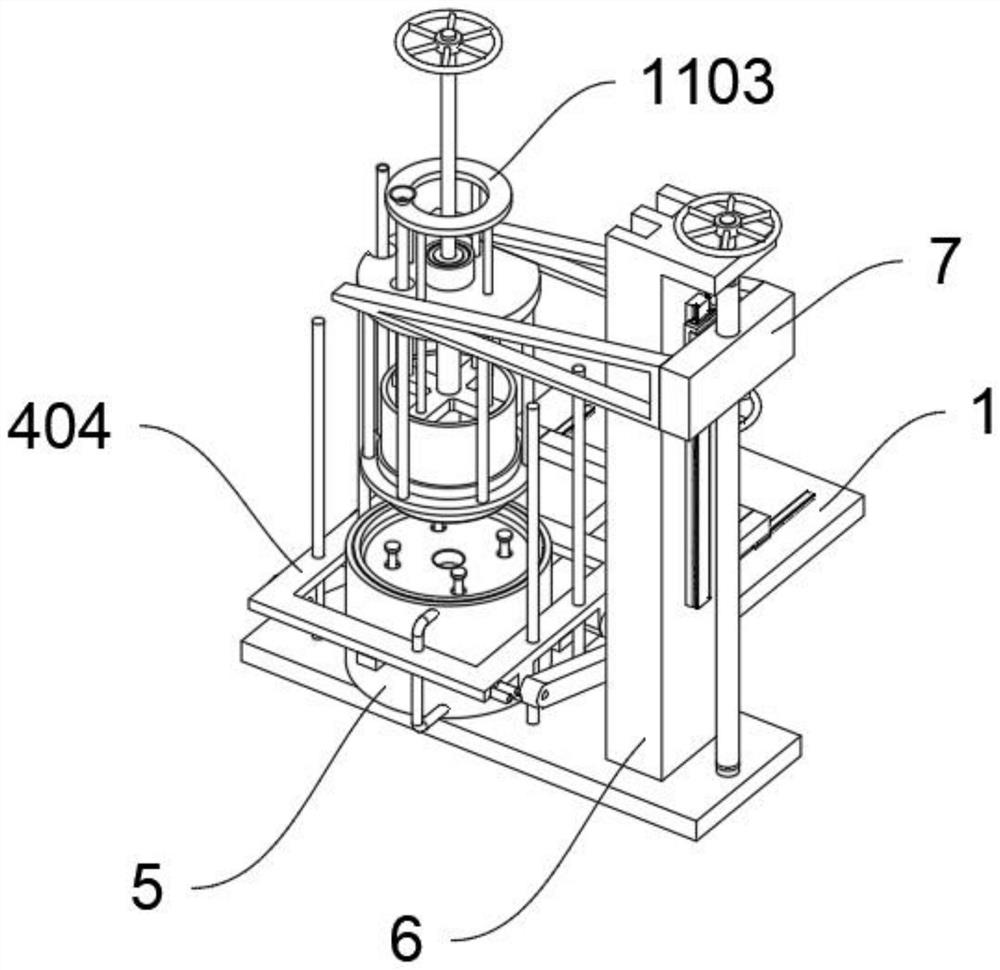

[0031] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a casting mold for a flywheel housing for engine casting, including a base 1; the base 1 also includes a push rod 101; The tops of the rods 101 are all tapered and trapezoidal structures; wherein, the base 1 also includes a guide rod A102 and a handwheel shaft 103; four sets of guide rods A102 are fixedly arranged on the front side of the base 1; Cylinder structure, the bearing is fixedly installed in the cylinder structure through interference fit, and the handwheel shaft 103 is fixedly arranged in the middle of the bearing through interference fit, and the handwheel shaft 103 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com