Connector and connector assembly

A technology of connectors and floating parts, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problems of low assembly efficiency and achieve the effects of high assembly efficiency, simplified structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

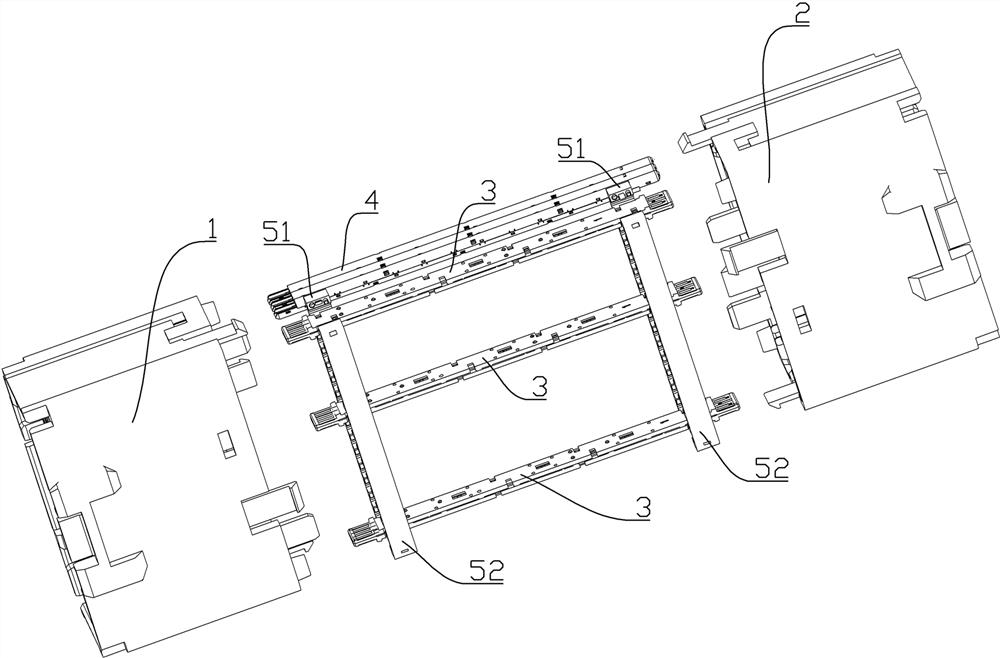

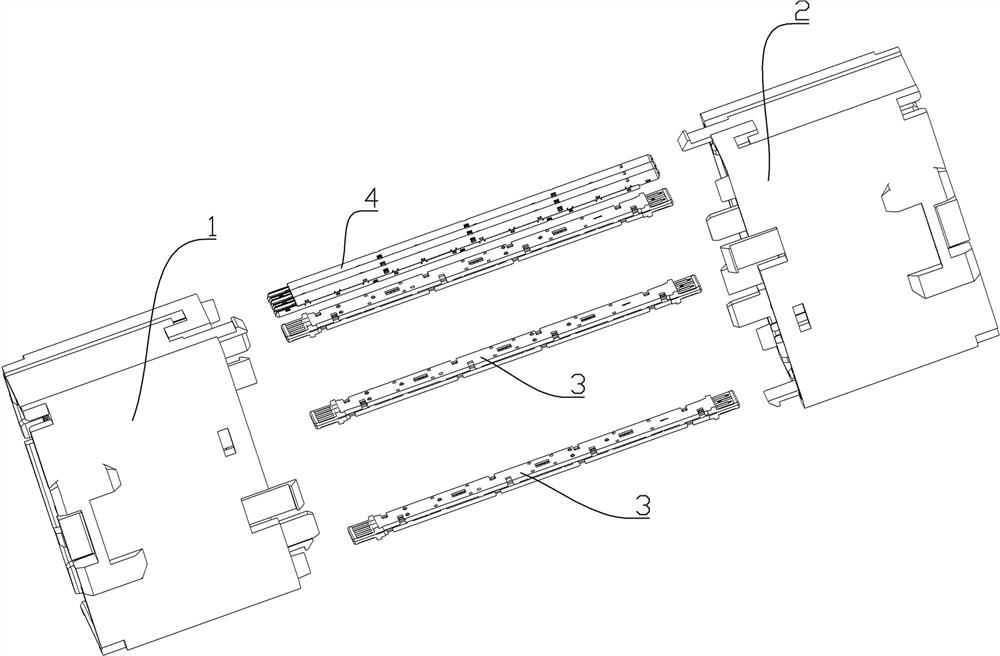

[0071] Such as figure 1 with figure 2 As shown, the connector assembly includes a transition connector, a first mating connector 1 and a second mating connector 2 adapted to the transition connector, wherein the first mating connector and the second mating connector The structure is the prior art and will not be described in detail.

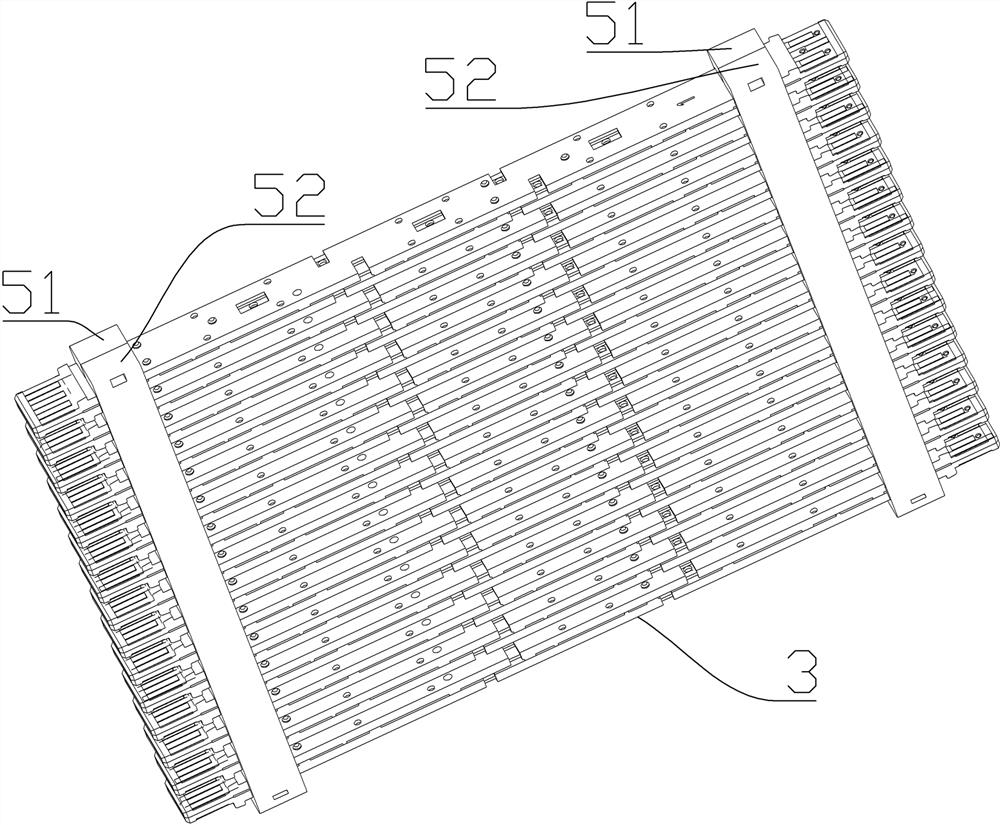

[0072] The transfer connector includes a housing (not shown in the figure) and a signal transmission module arranged in the housing. The housing includes two housing units with the same structure. The opposite ends of the two housing units have a The opposite ends of the two housing units are provided with an end plate that restricts the signal transmission module from coming out, and the end plate is provided with a through hole for the signal transmission module to pass through. The shell structure is the prior art, for example, it may be the shell of the transfer connector disclosed in the application publication number CN109659755A, and th...

specific Embodiment 2

[0082] The specific embodiment 2 of the connector assembly of the present invention, the difference between the structure of the connector assembly in this embodiment and the above-mentioned specific embodiment 1 of the connector assembly is only that:

[0083] In this example, if Figure 7 As shown, the first card bar 201 and the second card bar 202 are not provided with a card slot for clearance matching with the signal transmission module, and the first card bar 201 and the second card bar 202 are all provided with L-shaped surfaces. The L-shaped surfaces on the clamping strip 201 and the second clamping strip 202 enclose the module matching hole 203 .

specific Embodiment 3

[0084] The specific embodiment 3 of the connector assembly of the present invention, the difference between the structure of the connector assembly in this embodiment and the above-mentioned specific embodiment 1 of the connector assembly is only that:

[0085] In this embodiment, the two clips are fixed by bolts. In other embodiments, when the clips are made of metal, they can also be fixed by welding; in other embodiments, the two clips can also be riveted. In other embodiments, when the clamping strips are fixed by bolts, the guide posts and guide grooves may not be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com