Low-voltage vacuum circuit breaker based on Internet of Things

A vacuum circuit breaker and Internet of Things technology, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems such as bellows damage, achieve extended service life, prolong service life, and avoid sealing performance from being affected Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

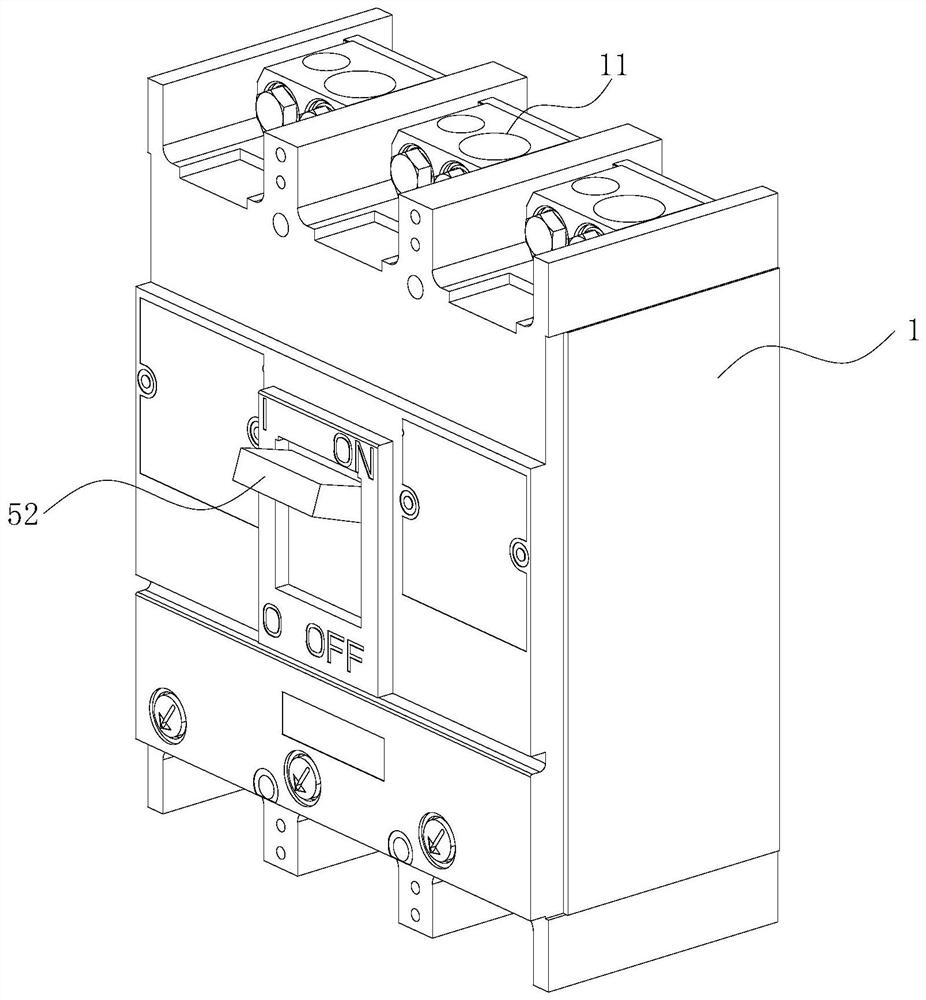

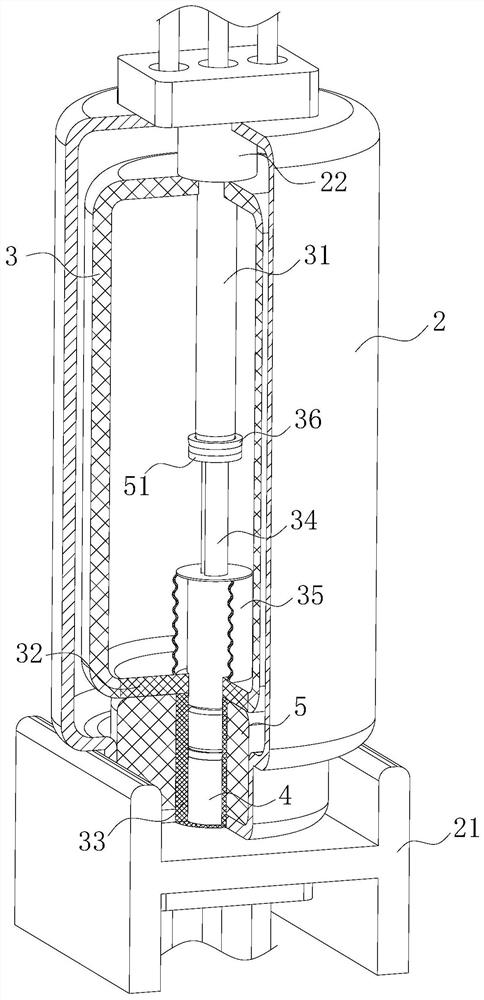

[0028] As an embodiment of the present invention, the moving end guide rod 34 is provided with a symmetrically designed first chute at one end inside the vacuum interrupter housing 3; the moving contact 36 connects with the moving end through the first chute. The sliding connection between the guide rods 34; the end of the moving contact 36 close to the moving end cover 32 is fixedly connected with a silicon steel ring; the outer side of the connecting pipe 33 is sleeved with an electromagnetic coil 5; the silicon steel ring is far away from the moving contact 36 side is fixedly connected with a permanent magnetic ring 51; the end of the cable housing 1 away from the opening of the first groove is provided with a slide switch 52; the slide switch 52 controls the electromagnetic coil 5 through the outer wall control circuit;

[0029] In the long-term working process, when the guide rod 34 at the follower end of the bellows 35 moves up and down, the wall of the bellows 35 is easi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com