Method for determining flow rate of fluid pumped by pump

A technology for conveying volume and flow, which is applied in the detection of fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, measurement devices, etc., which can solve problems such as increasing the complexity of the pump and occupying the installation space and reducing the efficiency of the pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

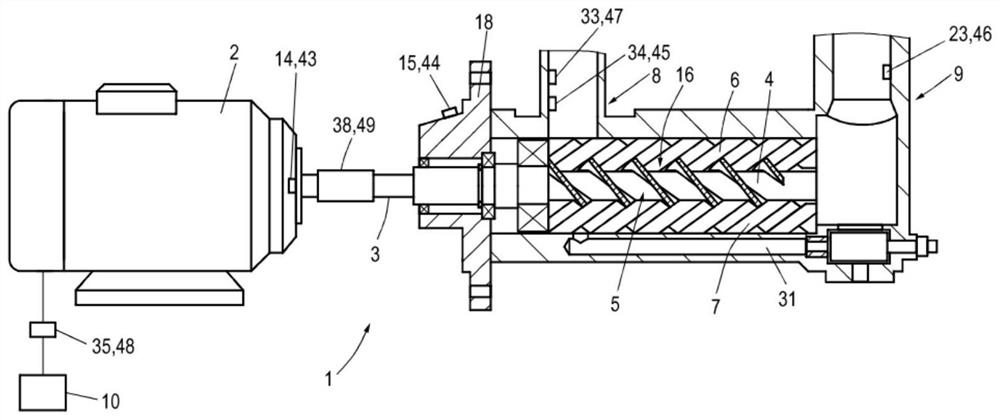

[0053] figure 1 A pump 1 is shown, in the example a progressive cavity pump. It comprises a motor 2 which drives a main screw 4 via a shaft 3 . The main screw 4 is also called drive screw. It is arranged in the vicinity of the secondary screws 6, 7 (also called running screws) so that in the resulting void 5 jointly formed by the main screw 4 and the secondary screws 6, 7, when the shaft 3 rotates, Fluid is delivered from fluid inlet 8 to fluid outlet 9 . Operating parameters of the pump 1 are recorded by a plurality of sensor devices 43 to 49 . Progressive cavity pumps are well known in the art and therefore should not be described in detail.

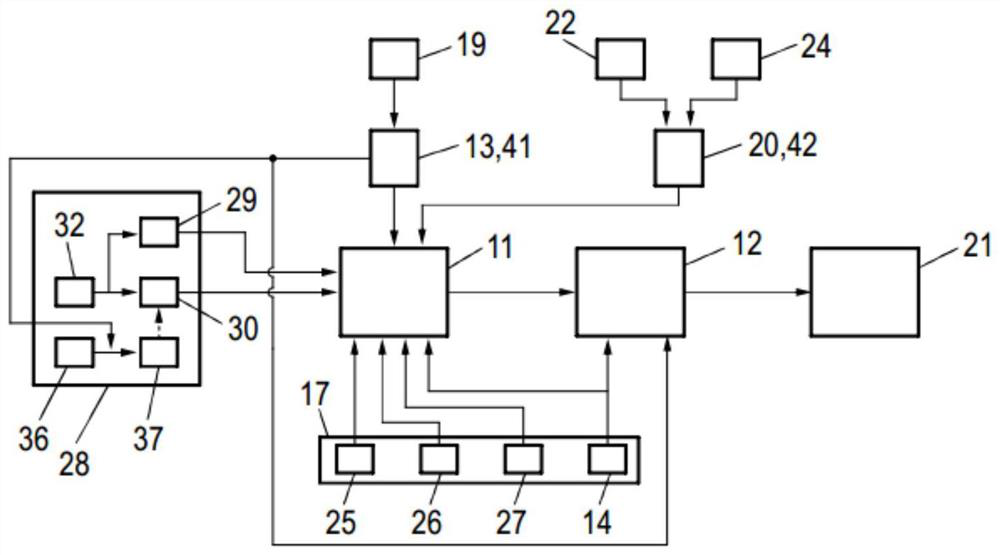

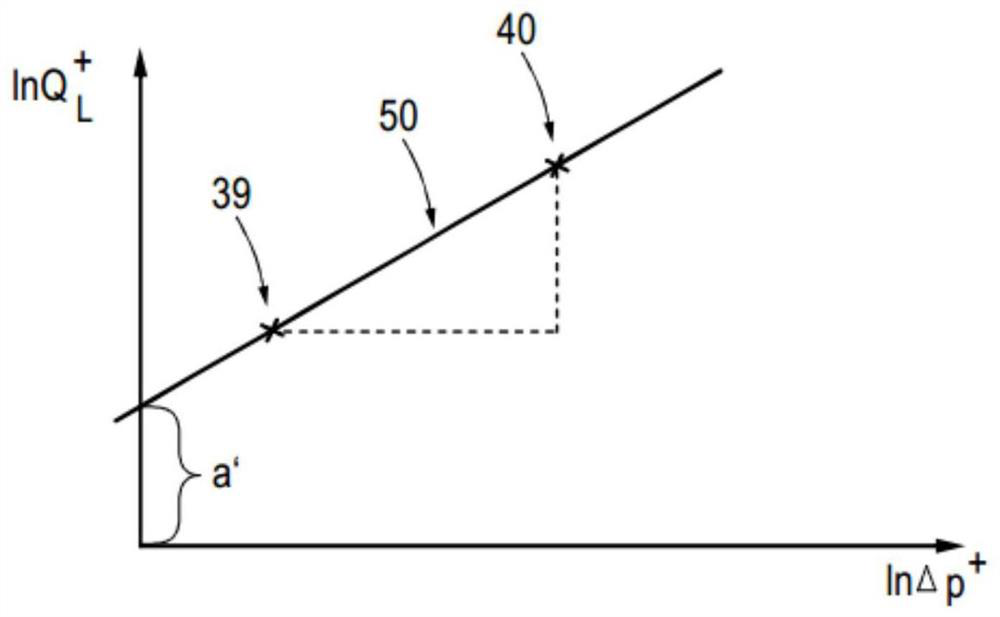

[0054] In many applications, the flow delivered from fluid inlet 8 to fluid outlet 9 is to be determined. Also refer below figure 2 options for this are listed. In principle, the leakage volume flow 11 , ie the fluid flowing back through the gap 16 in the pump 1 , can be completely ignored. In this case, the settable delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com