A micro-force-measuring three-dimensional comprehensive thread measuring machine probe and its measuring method

A measuring machine and force measuring technology, which is applied in the field of measurement, can solve the problems of affecting the quality level of the thread, the details cannot be controlled, and it is difficult to accurately measure the geometric shape and parameter information, so as to achieve compact structure, no crawling phenomenon, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

[0049] illustrate:

[0050] "Micrometric displacement" means a few micrometers to tens of micrometers.

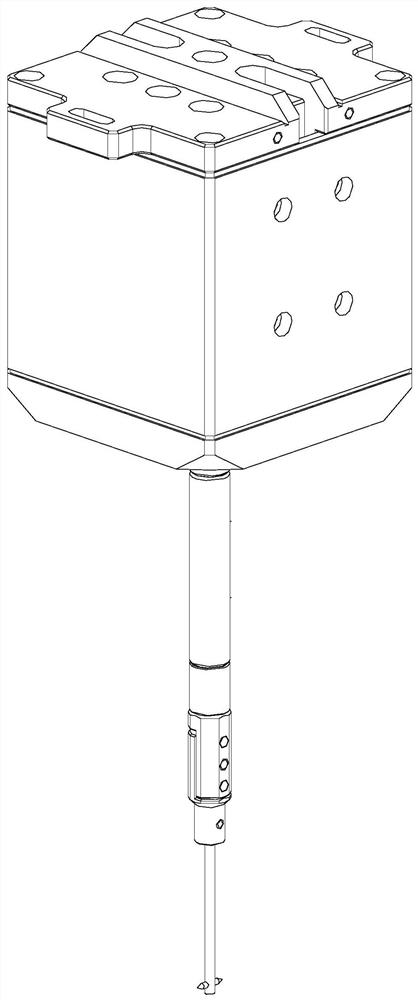

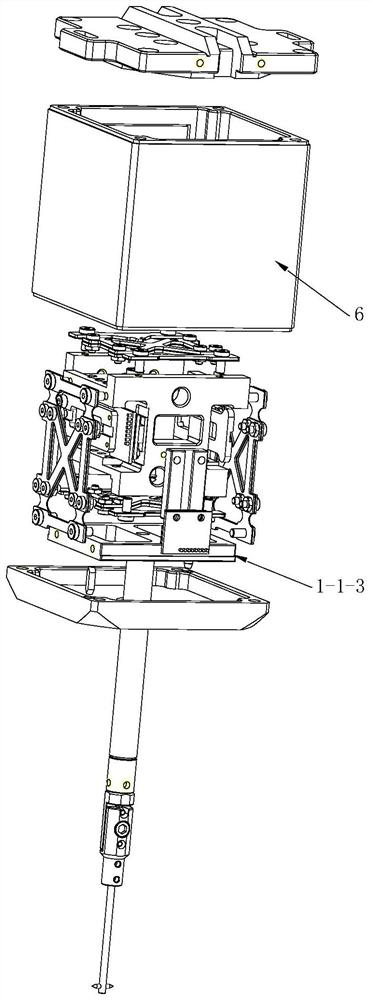

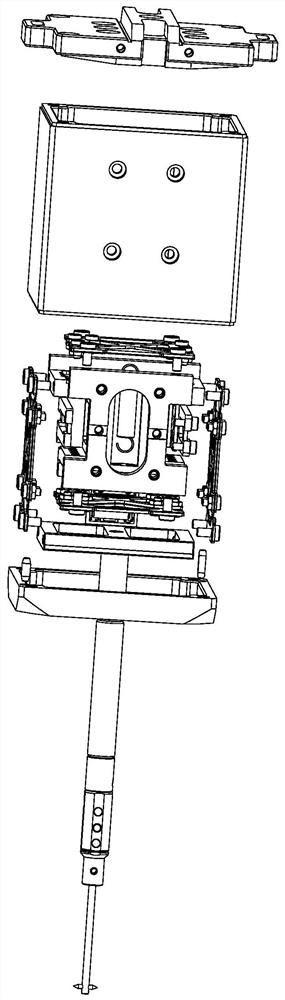

[0051] Such as Figures 1 to 5A , a three-dimensional comprehensive thread measuring machine probe of micro-force force measurement, comprising a lateral micrometric displacement system, a longitudinal micrometric displacement system, and a casing 6;

[0052] Such as Image 6 As shown, the lateral micrometric displacement system includes a lateral mechanical system and a lateral linear grating measurement system, and the lateral mechanical system includes a first lateral parallel reed group 1-1-1, a lateral second parallel reed group 1 -1-2, translation plate 1-1-3, intermediate body 3, the translation plate 1-1-3 is connected to the measuring rod 4, and the horizontal linear grating measurement system includes a horizontal reading head 1-2- 1. Horizontal gratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com