Fabricated type floor framework installation structure

An installation structure and assembly technology, which is applied to floors, building structures, partial raised floors, etc., can solve problems such as inability to perform accurate leveling, long wet work period, complicated welding process, etc., to improve the overall Installation effect, controllable sizing, and convenient post-maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

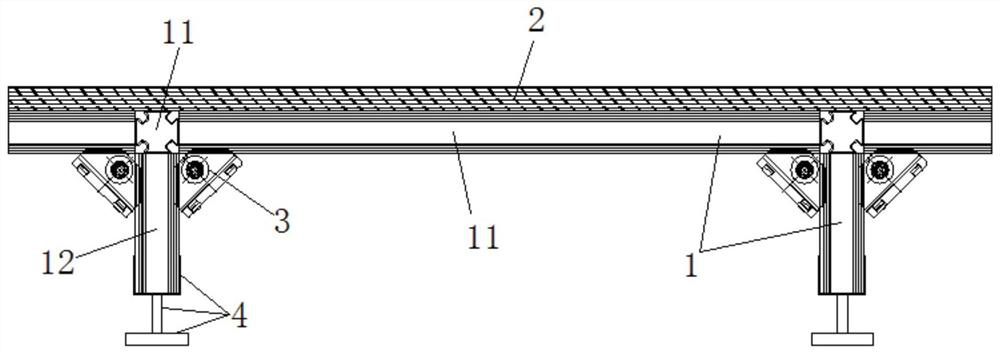

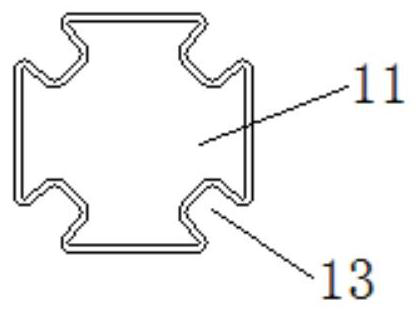

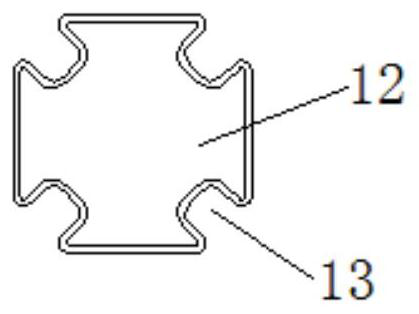

[0035] see Figure 1 to Figure 3 , the figure shows a prefabricated ground frame installation structure provided by Embodiment 1 of the present invention, including: a keel frame 1, which includes a transverse keel 11 and a vertical keel 12, and the vertical keel 12 is arranged on the side of the transverse keel 11 Bottom; bearing plate 2, which is arranged on the top surface of the keel frame 1; connecting member 3, which is arranged between the transverse keel 11 and the vertical keel 12, and connects the transverse keel 11 and the vertical keel 12; leveling piece 4, It is located at the base of the ground, and is arranged at the bottom of the vertical keel 12 , and the vertical keel 12 is engaged with the leveling member 4 .

[0036] An assembled ground frame installation structure provided in this embodiment mainly includes a keel frame 1, a bearing plate 2, a connecting member 3 and a leveling piece 4, the keel frame 1 includes a horizontal keel 11 and a vertical keel 12,...

Embodiment 2

[0045] see figure 1 , Figure 5 , the figure shows a prefabricated ground frame installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: leveling parts 4 includes base plate 41, adjusting rod 42 and supporting plate 43, base plate 41 and supporting plate 43 are located at the top and bottom of adjusting rod 42 respectively; The top is threadedly connected to the bottom of the supporting plate 43 . Through the setting of the above structure, the leveling is convenient, the installation is more convenient, the connection is more stable, and the overall installation effect is better.

Embodiment 3

[0047] see Figure 1 to Figure 4 , the figure shows a prefabricated ground frame installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the vertical keel 12 and the four corners of the transverse keel 11 are provided with clamping slots 13; the connecting member 3 is provided with a first clamping plate 31 and a second clamping plate 32, the first clamping plate 31 and the second clamping plate 32 are perpendicular ; The first clamping plate 31 and the second clamping plate 32 are clamped with the clamping groove 13; the first clamping plate 31 and the second clamping plate 32 are arranged in pairs; each vertical keel 12 is provided correspondingly Two connection members 3 . Through the setting of the above structure, the first clamping plate 31 and the second clamping plate 32 are arranged in pairs, which just correspond to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com