Grass planting pavement brick for environment-friendly construction and laying method thereof

A technology for pavement bricks and grass planting, applied in chemical instruments and methods, roads, roads, etc., can solve problems such as slow growth, larger gaps in grass-planting bricks, and damage to grass-planting bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

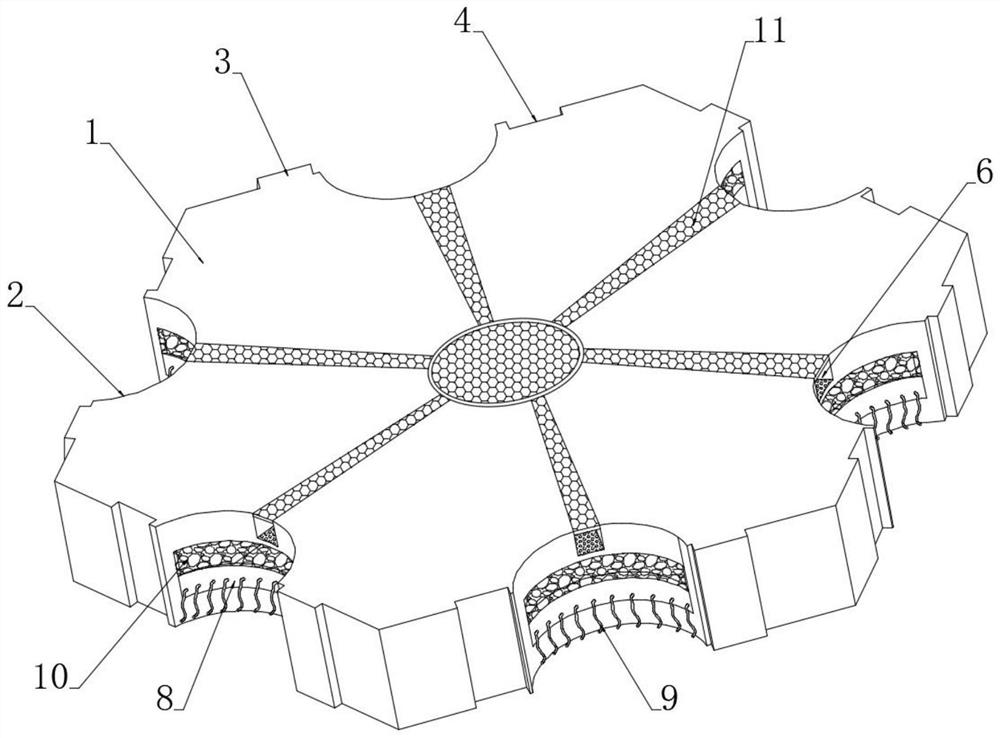

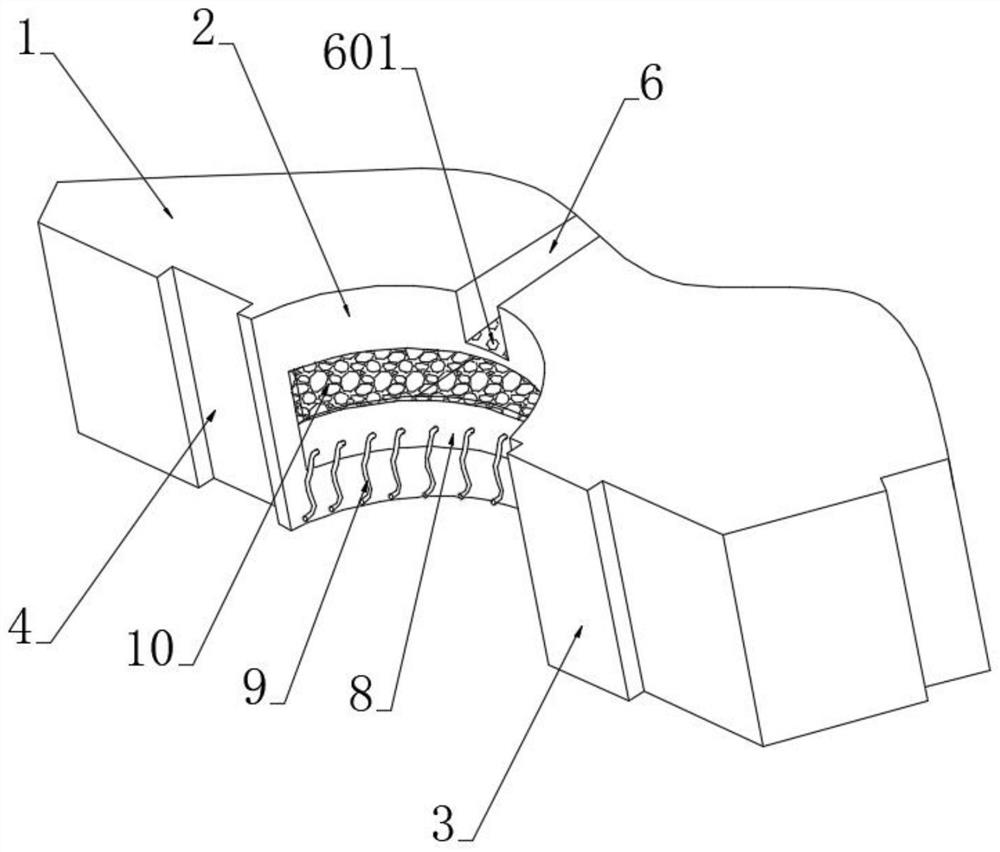

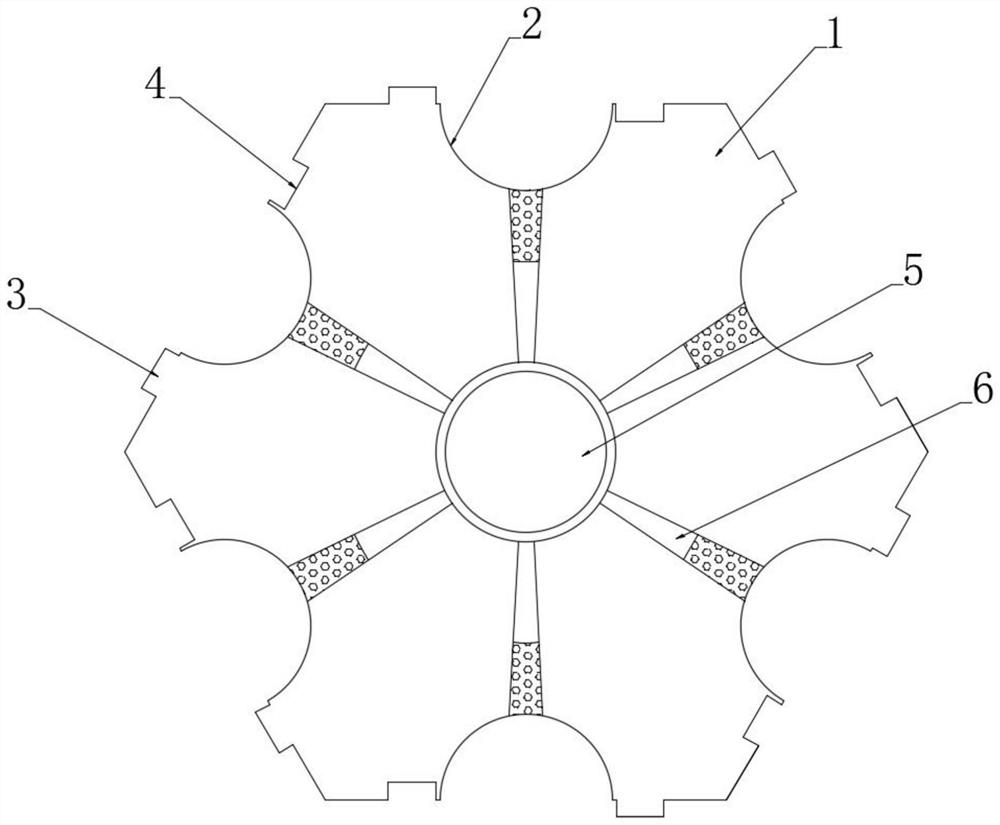

[0038] see Figure 1-3 and Figure 6, a grass planting pavement brick for environmental protection construction, comprising a hexagonal brick body 1 and a grass planting hole 2 opened on the hexagonal side wall of the hexagonal brick body 1, and the hexagonal side walls of the hexagonal brick body 1 are provided with mutually matching The embedding protrusions 3 and the embedding grooves 4 are provided, and the oppositely arranged embedding protrusions 3 and the embedding grooves 4 are symmetrically distributed on both sides of the grass planting hole 2, and the embedding protrusions 3 and The embedding grooves 4 are matched and staggered so that when two adjacent hexagonal brick bodies 1 are docked, the mutually matching embedding protrusions 3 and embedding grooves 4 can be embedded with each other, effectively improving the firmness of splicing. The middle part of the top of the side brick body 1 is provided with an external water storage chamber 5, and the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com