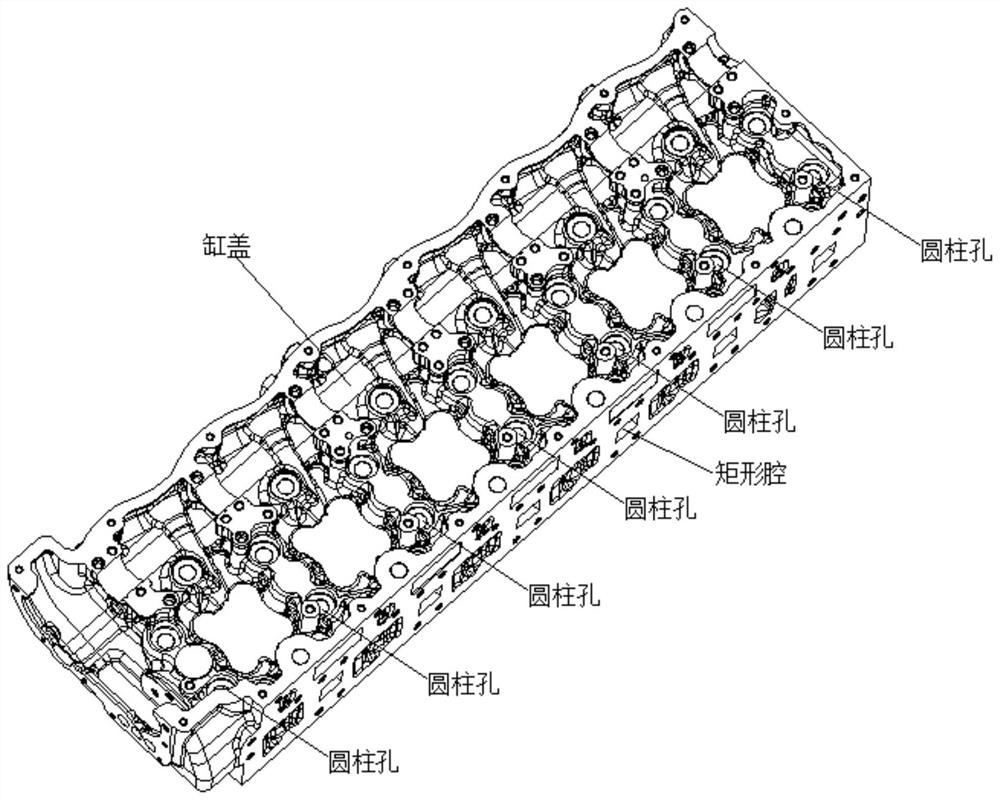

Engine cylinder cover lifting appliance and locking method

A technology of engine cylinder head and hoisting gear, applied in the field of hoisting gear, can solve problems such as collision accidents, damaged surfaces, easy to wear engine cylinder head, etc., and achieve safe and reliable hoisting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

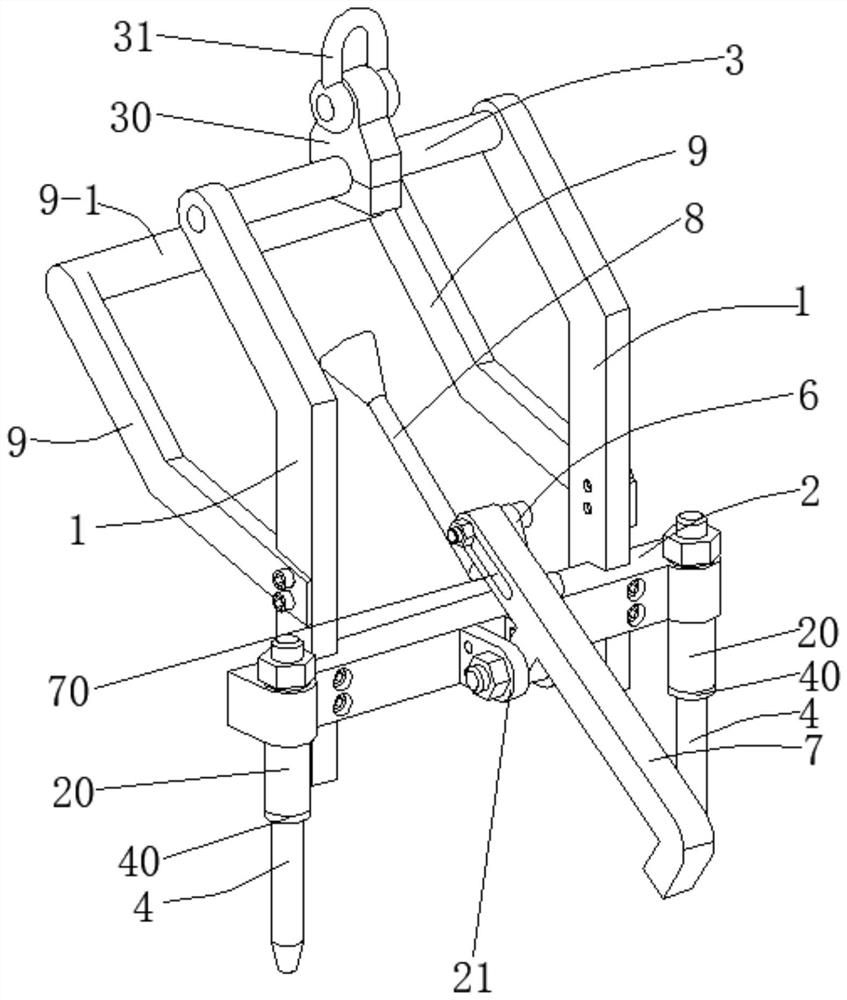

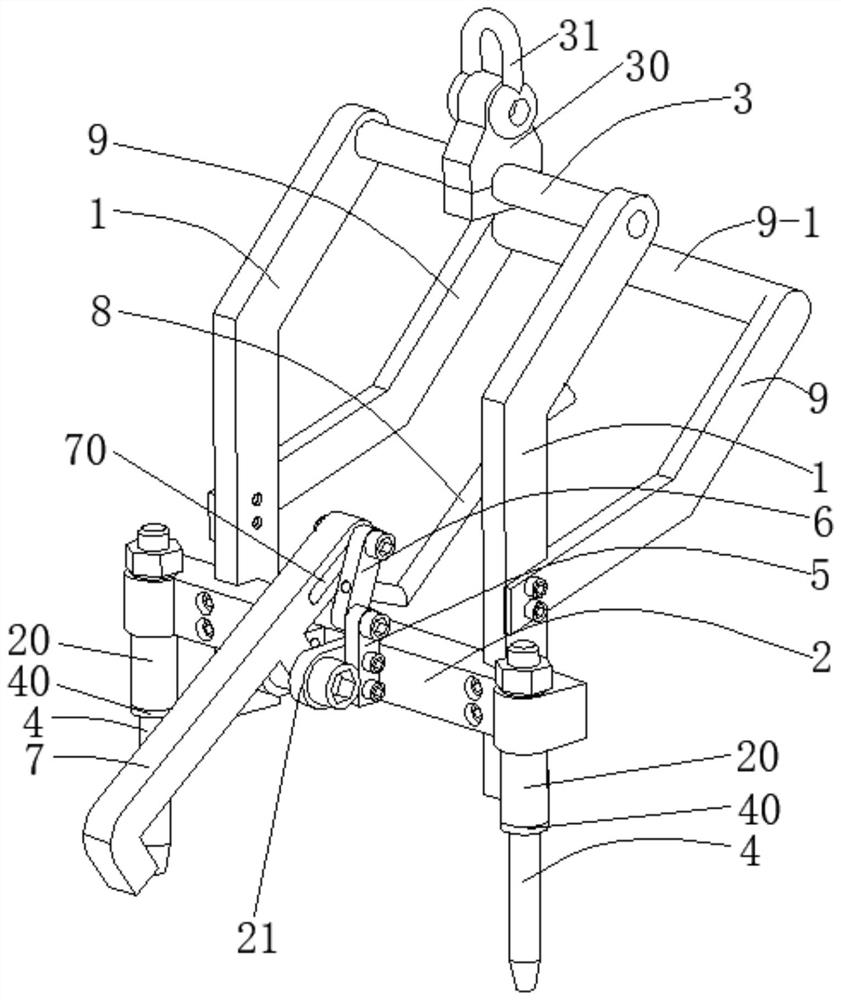

[0053] For the engine cylinder head hanger, hook the suspension ring 31 with the hook at the lower end of the vehicle, then hang the engine cylinder head hanger of the present invention to the engine cylinder head upper end, then hold the handle bar 9-1 by hand, and release the engine down. Cylinder head hanger, so that the long pin 4 is inserted into the two cylindrical holes in the middle of the upper end of the engine cylinder head, then hold the operating rod 8, straighten the operating rod 8 and push it forward, and then the connecting rod 2 6 is wound around the connecting rod The hinge of one 5 rotates forward, and the pin shaft at the upper end of the connecting rod 2 6 pushes the connecting rod 3 7 to rotate downward around the hinge seat through the long slot 70. When the connecting rod 2 6 rotates to the horizontal state, the connecting rod 3 7 Rotate to the vertical state, at this time the hook at the end of the connecting rod 3 7 is inserted into the rectangular ca...

Embodiment 2

[0058] On the basis of Embodiment 1, the lower end surface of the support cylinder 20 is flush with the lower end surface of the longitudinal arm 1, and rubber pads are attached to the lower end surface of the support cylinder 20 and the lower end of the longitudinal arm 1 to avoid the support cylinder 20 The lower end surface of the longitudinal arm 1 is directly in contact with the finishing surface of the engine cylinder head to ensure the accuracy of the finishing surface of the engine cylinder head; the longitudinal arm 1 is divided into an upper arm and a lower arm, and the angle between the upper arm and the lower arm is 110°-140°, which ensures that after the engine cylinder head is hoisted, the center of gravity of the entire engine cylinder head and the spreader is located in the middle as much as possible to ensure the horizontal hoisting of the engine cylinder head; the middle of the cross brace 3 is fastened with lifting lugs 30, the lifting lug 30 is hinged with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com