Ceramic spraying type uniform glazing device

A uniform and ceramic technology, applied in the field of ceramic spraying uniform glazing device, can solve the problems of ceramic glazing, uneven glazing, low efficiency of ceramic glazing, etc., and achieve the effect of meeting the glazing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

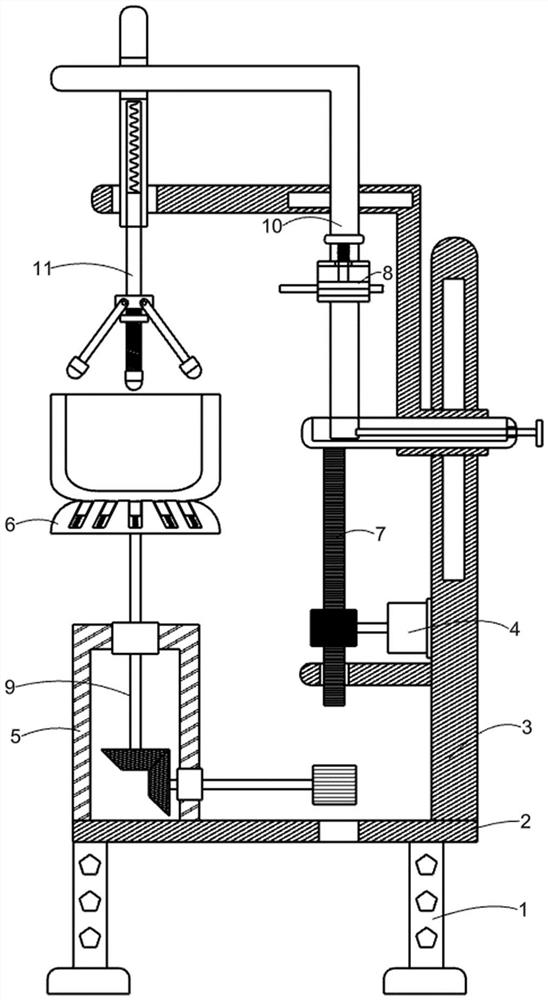

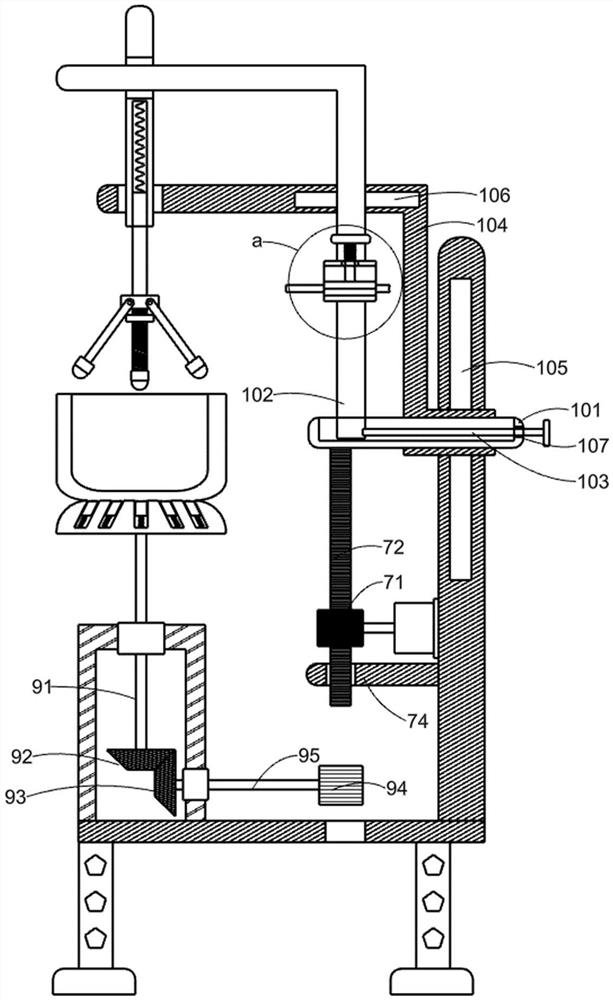

[0024] Specific implementation mode one: a ceramic spraying type uniform glazing device, such as Figure 1-7 As shown, it includes a base 1, a base plate 2, a mounting plate 3, a servo motor 4, a mounting frame 5, a placement plate 6, a lifting component 7, a clamping component 8, a rotating component 9, an adjusting component 10 and a positioning component 11. The substrate 2 is fixed on the upper end of the base 1, the mounting plate 3 is fixed on the upper side of one end of the substrate 2, the servo motor 4 is fixed on one side of the mounting plate 3 and is located above the substrate 2, the The mounting frame 5 is fixedly arranged on the upper side of the base plate 2 and away from the mounting plate 3, the lifting assembly 7 is arranged on the mounting plate 3, the rotating assembly 9 is located on the mounting frame 5, and the placement plate for placing ceramics 6 is arranged on the rotating assembly 9, the adjusting assembly 10 is arranged on the mounting plate 3 an...

specific Embodiment approach 2

[0035] Specific implementation mode two: on the basis of specific implementation mode two, such as Figure 6 As shown, it also includes a third elastic member 12 and a corrugated friction block 14. Five grooves 13 are opened on the placement plate 6, and the third elastic member 12 is fixed in the grooves 13. The corrugated friction The block 14 is fixed on one end of the third elastic member 12 .

[0036] The function of the corrugated friction block 14 is to increase the frictional force between the ceramics and the placing plate 6, so as to prevent the ceramics from sliding left and right when the ceramics are glazed, so that the spray pipe can evenly spray the glaze on the ceramics. on the outer wall.

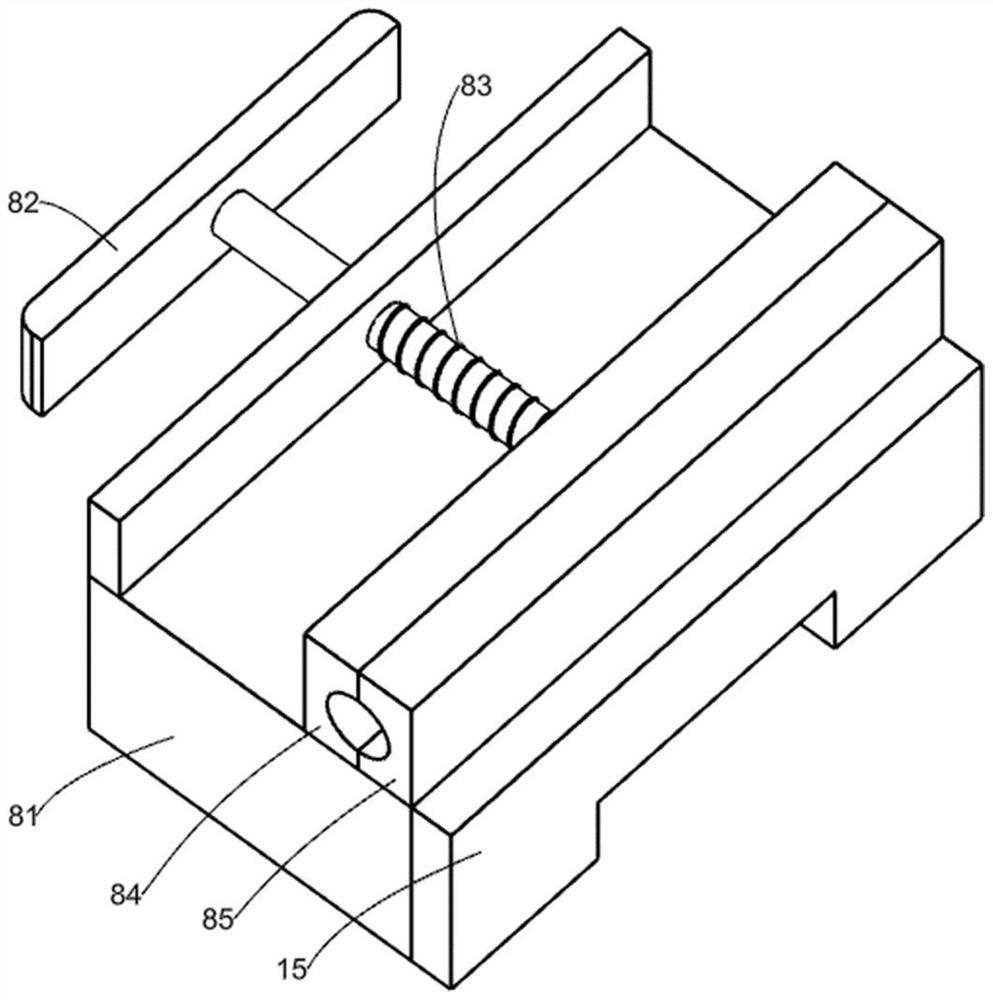

[0037] Such as Figure 7 As shown, a magnet block 15 for adjusting the position of the connecting block 81 is also included. The magnet block 15 is slidably arranged on the adjusting plate 102 and the bottom side of the connecting block 81 is fixedly connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com