Device and method for treating automobile maintenance spraying waste gas through activated carbon adsorption and desorption catalytic combustion

A technology of activated carbon adsorption and catalytic combustion, which is applied in combustion methods, chemical instruments and methods, gas treatment, etc., can solve problems such as unsatisfactory treatment effect of the device and inability to meet environmental protection management, etc., to achieve continuous adsorption, improve adsorption efficiency and use. Longevity, the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

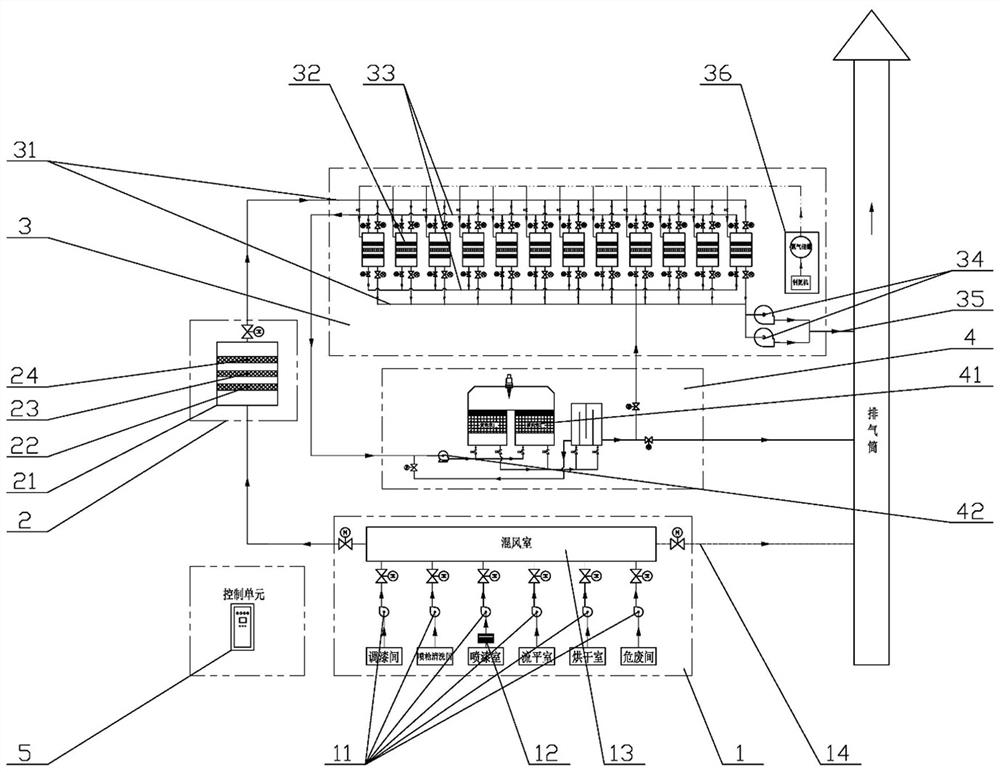

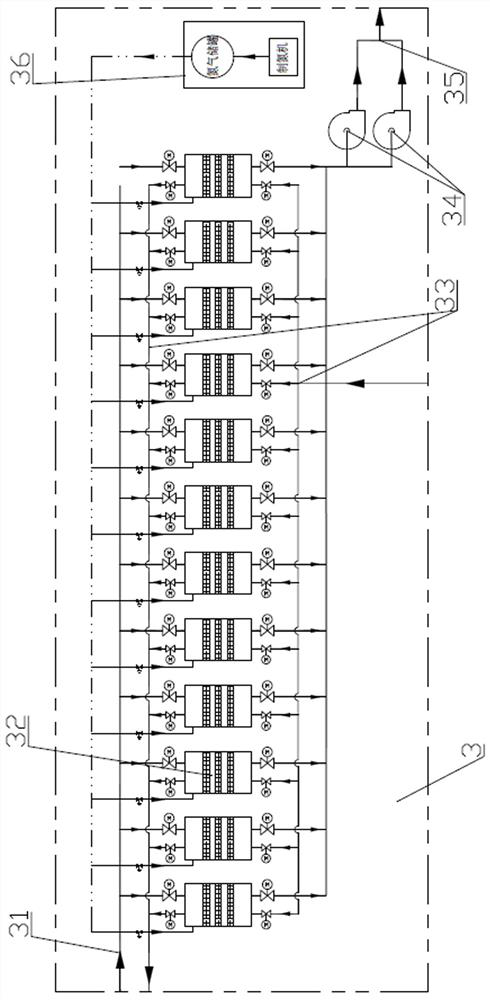

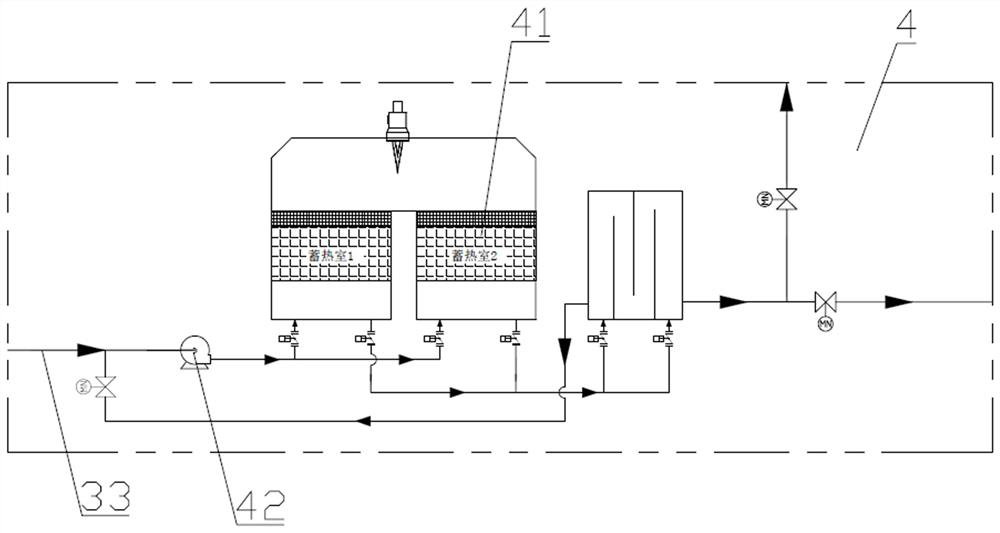

[0042] The invention provides an activated carbon adsorption-desorption catalytic combustion device for treating exhaust gas from automobile maintenance, including a collection and mixing unit 1 , a pretreatment unit 2 , an activated carbon adsorption-desorption unit 3 , a catalytic combustion unit 4 and a control unit 5 .

[0043] The collection and mixing unit 1 communicates with the exhaust system of the paint mixing room, the spray gun cleaning room, the paint spraying room, the leveling room, the drying room and the hazardous waste room respectively through the collecting pipeline. The induced draft fans 11 of each process link are installed in the corresponding collection pipelines. The exhaust gas in the paint mixing room, spray gun cleaning room, spray paint room, leveling room, drying room and hazardous waste room plays an important role in the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com