Plant roast beef flavor seasoning and preparation method and application thereof

A roast beef and flavoring technology, which is applied in the fields of food processing, seasoning or food additives, can solve the problems of lack of original flavor of meat and lack of characteristic flavor, etc., achieve no miscellaneous aroma, overcome the lack of characteristic flavor, and strong characteristic flavor of roast beef Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

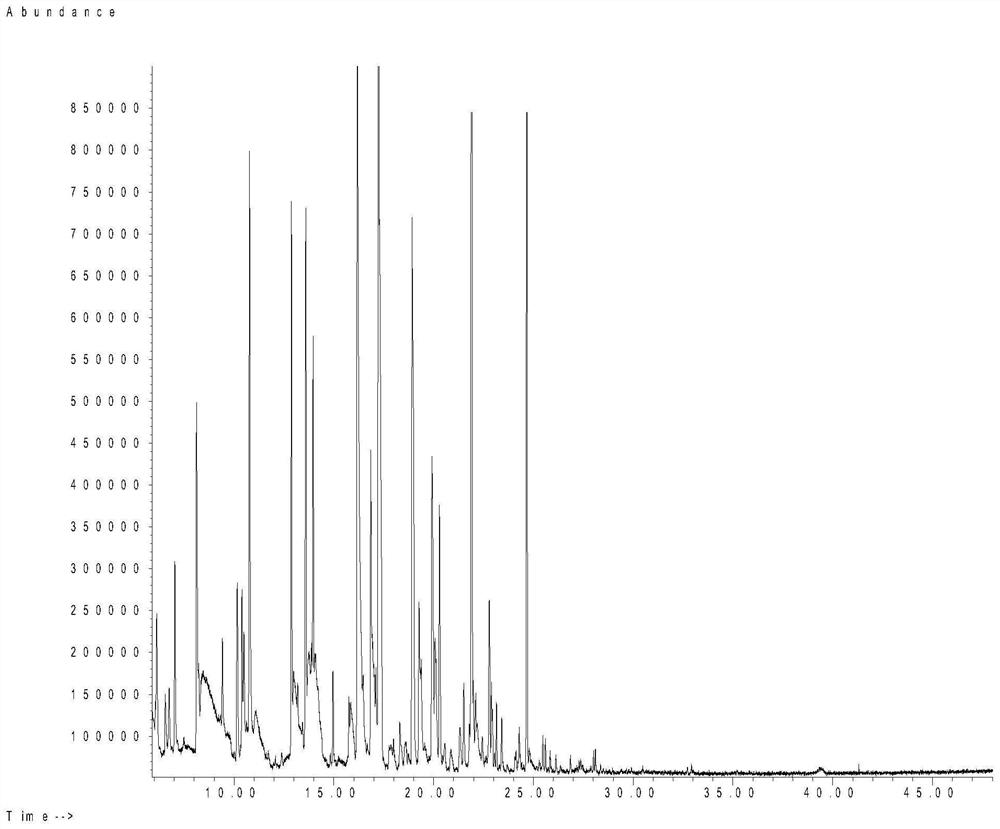

Image

Examples

Embodiment 1

[0049] Embodiment 1: the preparation of F-1

[0050] (1) Dilute the following flavor substances with a solvent to a concentration of 1%, and form a mixture according to the following parts by weight to obtain product A:

[0051] Product A formula composition

[0052]

[0053] (2) Add cysteine, serine and xylose to a certain amount of phosphate buffer with a pH value of 6, wherein the concentration of cysteine is 6M, and the concentration of serine is 10M. The molar ratio of sugar is 1:1.6, react at 45°C for 3 hours, and concentrate in vacuo to obtain product B;

[0054] (3) In a certain amount of phosphate buffer solution with a pH value of 6, add lysine and xylose, the concentration of lysine is 3M, and the molar ratio of lysine and xylose is 1:1. Reacted for 0.5h to obtain product C;

[0055] (4) In a certain amount of soybean protein isolate, add water according to the ratio of solid to liquid at 1:5 (g:mL), at a temperature of 55°C, and at pH 7.0, first add trypsin...

Embodiment 2

[0058] Embodiment 2: the preparation of F-2

[0059] (1) Dilute the following flavor substances with a solvent to a concentration of 1%, and prepare a mixture according to the following parts by weight to obtain product A;

[0060] Product A formula composition

[0061]

[0062]

[0063] (2) Add cysteine, serine and xylose to a certain amount of phosphate buffer with a pH value of 5, wherein the concentration of cysteine is 6M, and the concentration of serine is 12M. The molar ratio of sugar is 1:2, react at 60°C for 0.5h, and concentrate in vacuo to obtain product B;

[0064] (3) In a certain amount of phosphate buffer solution with a pH value of 6, add lysine and xylose, the concentration of lysine is 6M, and the molar ratio of lysine and xylose is 1:5 and react at 100°C 1h, product C was obtained;

[0065] (4) Add water to a certain amount of soybean protein isolate according to the ratio of material to liquid: 1: (5-10) (g: mL), and at a temperature of 55°C and ...

Embodiment 3

[0068] Embodiment 3: the preparation of F-3

[0069] (1) Dilute the following spices with a solvent to a concentration of 1%, and then formulate a mixture according to the following parts by weight to obtain product A;

[0070]

[0071] (2) Add cysteine, serine and xylose in a certain amount of phosphate buffer solution with a pH of 5, wherein the concentration of cysteine is 6-10M, the concentration of serine is 12M, and the concentration of cysteine The molar ratio with reducing sugar is 1:1, react at 50°C for 1.5h, and concentrate in vacuo to obtain product B;

[0072] (3) In a certain amount of phosphate buffer solution with a pH value of 6, add lysine and xylose, the concentration of lysine is 4M, the molar ratio of lysine and reducing sugar is 1:5, at 90°C Reaction 8min, obtain product C;

[0073] (4) Add water to soybean protein isolate at a material-to-liquid ratio of 1:8 (g:mL), enzymolysis temperature is 55°C, and pH 7.0, first add trypsin to enzymolysis at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com