Pet cat feed formula and preparation method thereof

A feed formula, pet technology, applied in the field of pet feed, can solve the problem of pet cats not eating feed and other problems, achieve the effects of gastrointestinal health, relieve stress, and increase food intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

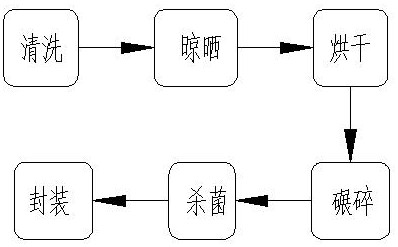

[0021] A preparation method of pet cat feed is characterized in that: its preparation method is as follows:

[0022] Step 1: Weigh the raw materials according to the ratio of claim 1, and clean the catnip, oat grass, and Polygonum arborescens with clean water and then dry them in the air;

[0023] Step 2: Dry the catnip and oat grass after drying, then mix and crush the two to form pieces with a diameter of less than 10mm;

[0024] Step 3: drying the dried Polygonum spp., and then crushing to form fragments with a diameter of less than 20 mm;

[0025] Step 4: Mix the fragments obtained in Step 2 and Step 3, and then carry out sterilization operation, and the sterilization time is 20-50min;

[0026] Step 5: Canning and packaging the sterilized mixture.

[0027] Further, the drying temperature of the step 2 is 50-60°C, and the drying time is 1-2h; further, the drying temperature of the step 3 is 60-70°C, and the drying time is 2-3h; further, the The sterilization method in st...

Embodiment 1

[0029] In terms of parts by weight, the following raw materials are included: 1 kg of catnip, 2 kg of oat grass, and 3 kg of Polygonum japonica.

[0030] According to the above proportioning, its preparation method is as follows:

[0031] Step 1: Weigh the raw materials, wash the catnip, oat grass, and Polygonum arborescens with clean water, and then dry them in the air;

[0032] Step 2: Dry the catnip and oat grass after drying, then mix and crush the two to form pieces with a diameter of less than 10mm. The drying temperature is 50°C and the drying time is 1 hour;

[0033] Step 3: Dry the dried Polygonum japonica, and then crush it to form fragments with a diameter of less than 20mm. The drying temperature is 60°C, and the drying time is 2 hours;

[0034] Step 4: Mix the fragments obtained in Step 2 and Step 3, and then carry out ultraviolet sterilization operation, and the sterilization time is 20 minutes;

[0035] Step 5: Canning and packaging the sterilized mixture, the...

Embodiment 2

[0037] In terms of parts by weight, the following raw materials are included: 3 kg of catnip, 5 kg of oat grass, and 5 kg of Polygonum japonica.

[0038] According to the above proportioning, its preparation method is as follows:

[0039] Step 1: Weigh the raw materials, wash the catnip, oat grass, and Polygonum arborescens with clean water, and then dry them in the air;

[0040] Step 2: Dry the catnip and oat grass after drying, then mix and crush the two to form pieces with a diameter of less than 10mm. The drying temperature is 50°C and the drying time is 2 hours;

[0041] Step 3: Dry the dried Polygonum spp., and then crush it to form pieces with a diameter of less than 20mm. The drying temperature is 70°C and the drying time is 2 hours;

[0042] Step 4: Mix the fragments obtained in Step 2 and Step 3, and then carry out ultraviolet sterilization operation, and the sterilization time is 30 minutes;

[0043] Step 5: Canning and packaging the sterilized mixture, the packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com