Spring for a check valve, check valve having a spring of this kind, controllable vibration damper having such a check valve, and motor vehicle having a controllable vibration damper of this kind

A technology of check valve and shock absorber, which is applied in the design characteristics of spring/shock absorber, functional characteristics of spring/shock absorber, spring/shock absorber, etc. It can solve the problem of large installation space of coil spring and achieve simple The effect of forming and high restoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

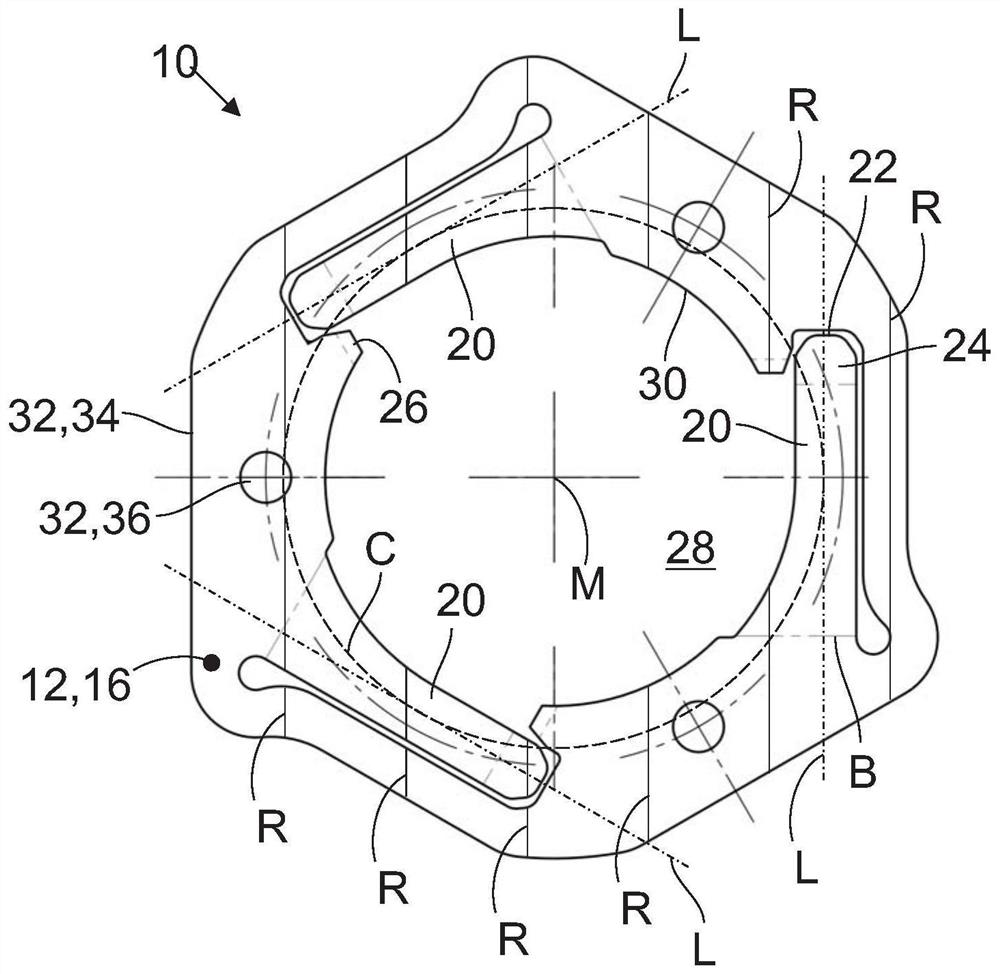

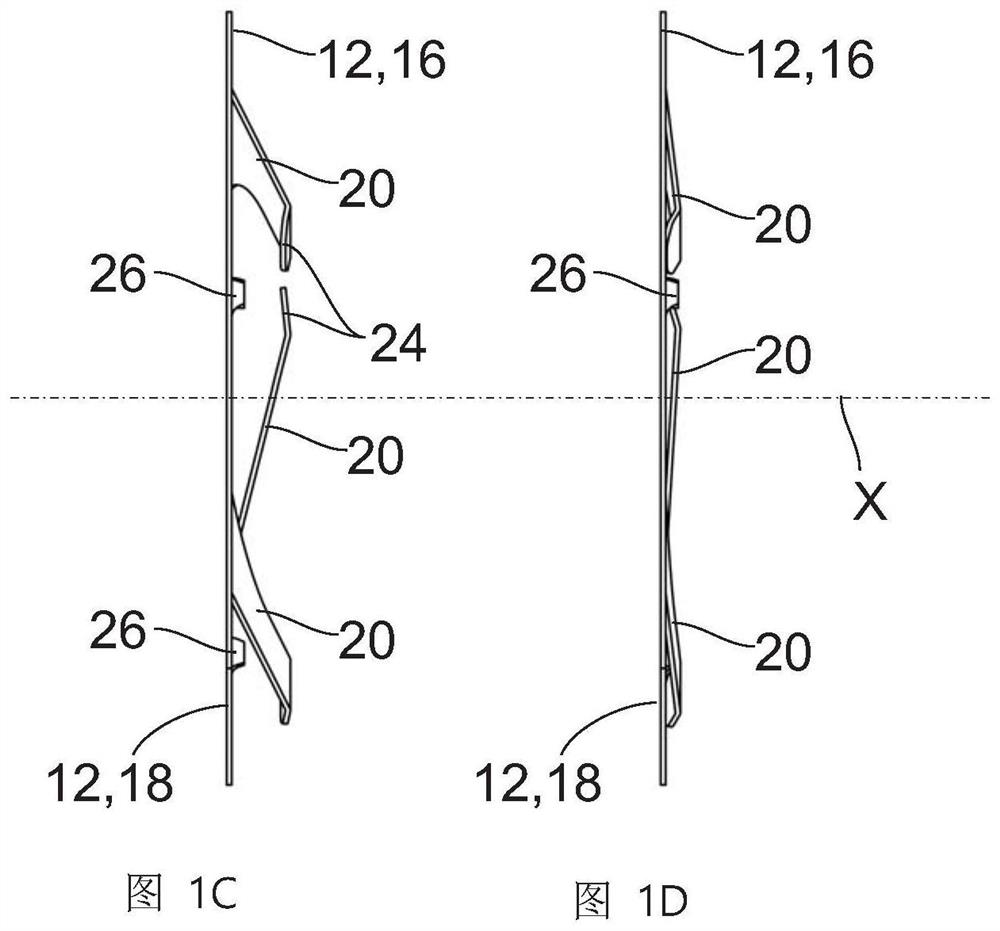

[0044] exist Figure 1A A first embodiment of a spring 10 according to the invention is shown in side view, and in Figure 1B A first embodiment of the spring 10 according to the invention is shown in plan view, wherein the spring 10 is in a not yet assembled state. The spring 10 has a laminar, in this case disk-shaped, base body 12 with a center point M, which forms a first surface 16 and a second surface 18 . Furthermore, the base body 12 forms three spring arms 20 which have an elongated shape and each have a free end 22 . The spring arms 20 are defined by corresponding cutouts in the base body 12 . Each spring arm 20 defines a longitudinal axis L extending through a free end 22 . The spring arms 20 are designed and aligned such that their longitudinal axis L runs tangentially to a circle C around the center point M of the base body 12 . In addition, the spring arms 20 are evenly distributed on the circumference of the circle C such that the longitudinal axes L enclose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com