Anti-explosion valve capable of bidirectionally protecting large air volume

A technology of large air volume and valve leaf, which is applied in the direction of safety valve, balance valve, valve device, etc., and can solve the problems that cannot be adapted to the occasion with large air volume, narrow air duct, and valve leaf cannot be closed with the valve body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

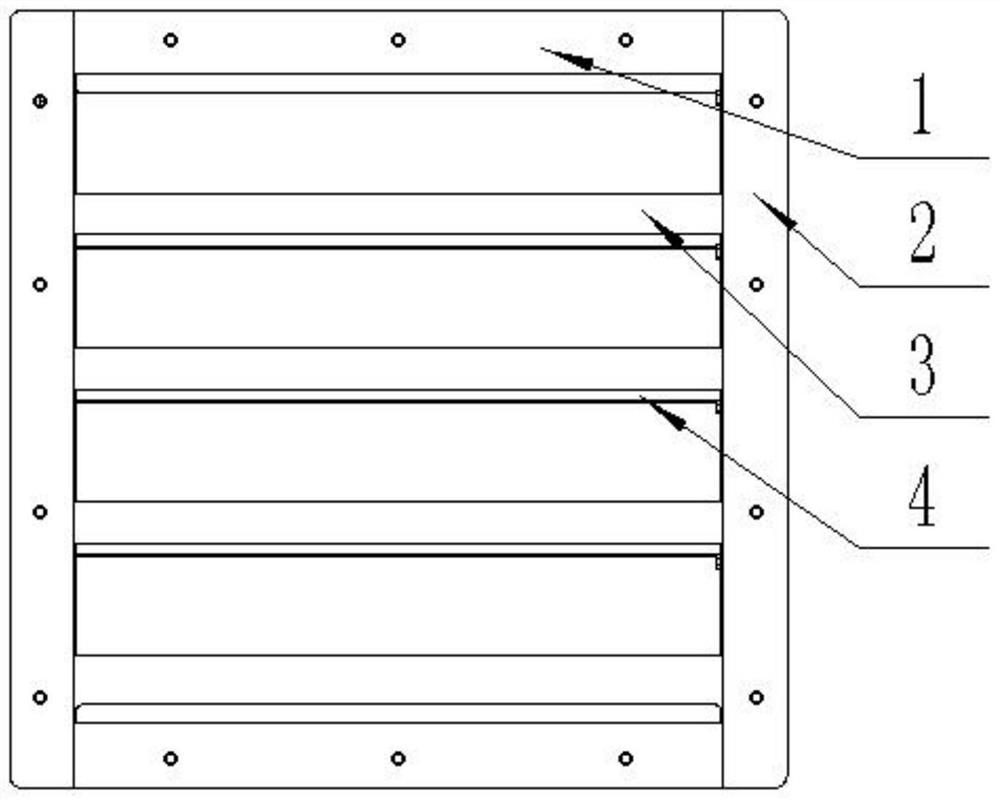

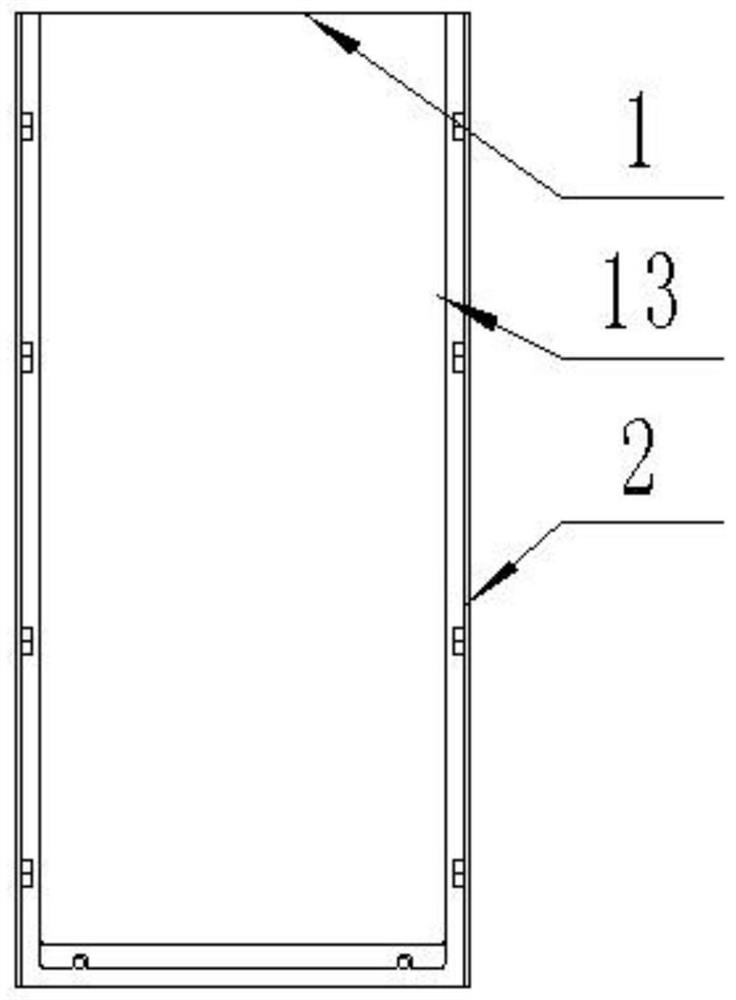

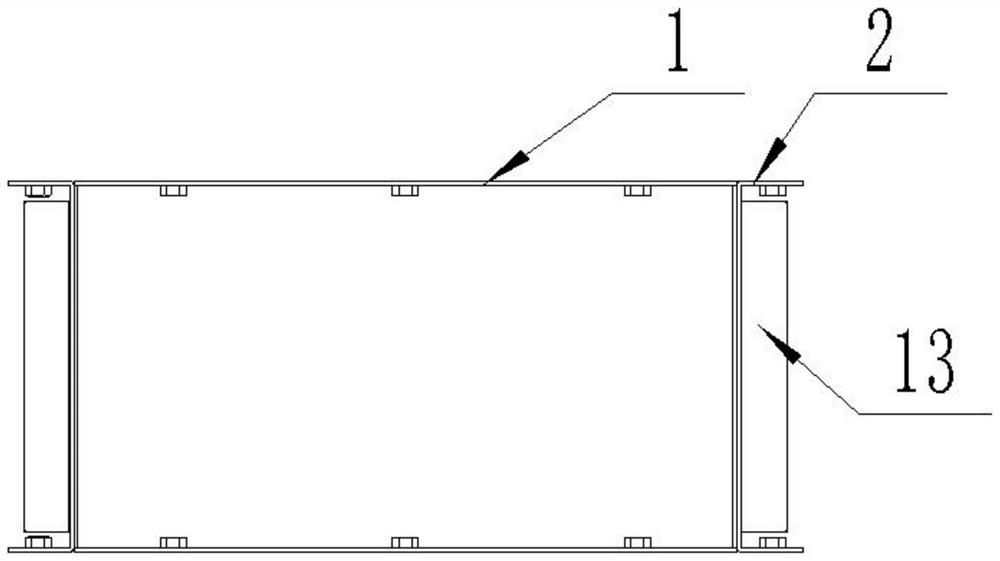

[0029] like Figure 1 to Figure 7 As shown, this specific embodiment adopts the following technical solutions: including a valve frame assembly and a set of valve leaf assemblies; the valve frame assembly includes a rectangular frame surrounded by upper and lower end plates 1 and left and right end plates 2, respectively Two sets of baffle plates 3 at the front and rear symmetrical positions of the upper and lower end plates 1; the valve leaf assembly includes shafts 4 that are equidistantly distributed in a rectangular frame and whose two ends respectively pass through the relative positions of the left and right end plates 2, and are arranged on the left and right end plates. 2 and the valve leaf 5 connected to the shaft 4, the No. 1 rotation positioning piece 6 arranged vertically on the side surface of the rectangular frame and located between the shaft 4 and the valve leaf 5, and the No. 1 rotation positioning piece 6 respectively. The connected connecting rod 7, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com