Assembled building buttress stabilizing device

A stable device and assembled technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as shaking, affecting installation accuracy, and unfavorable construction operations, so as to simplify operations, improve work efficiency, and improve flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

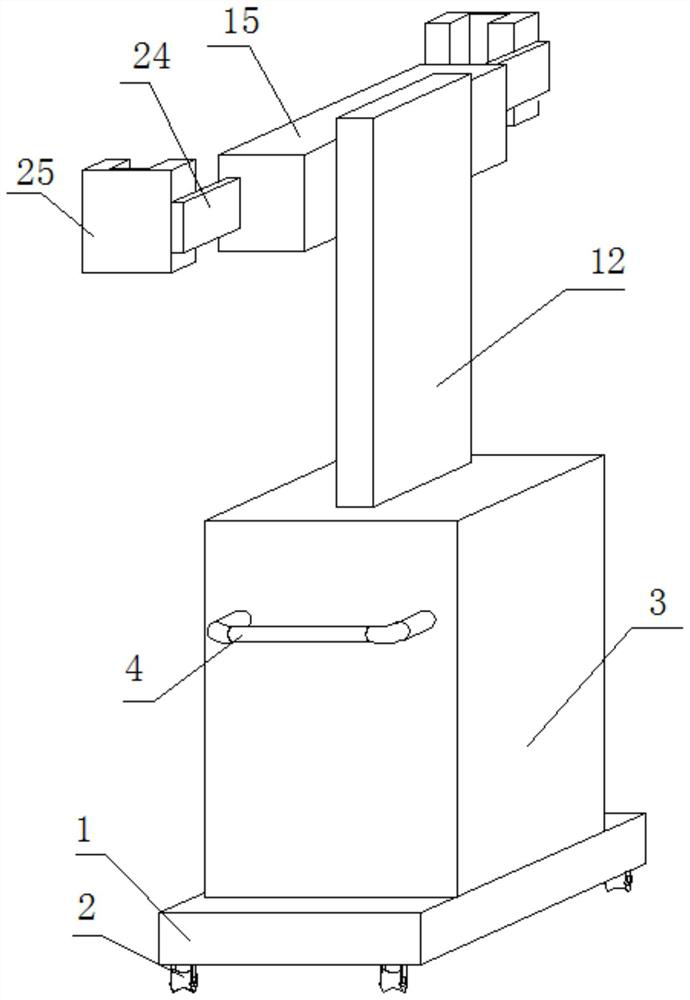

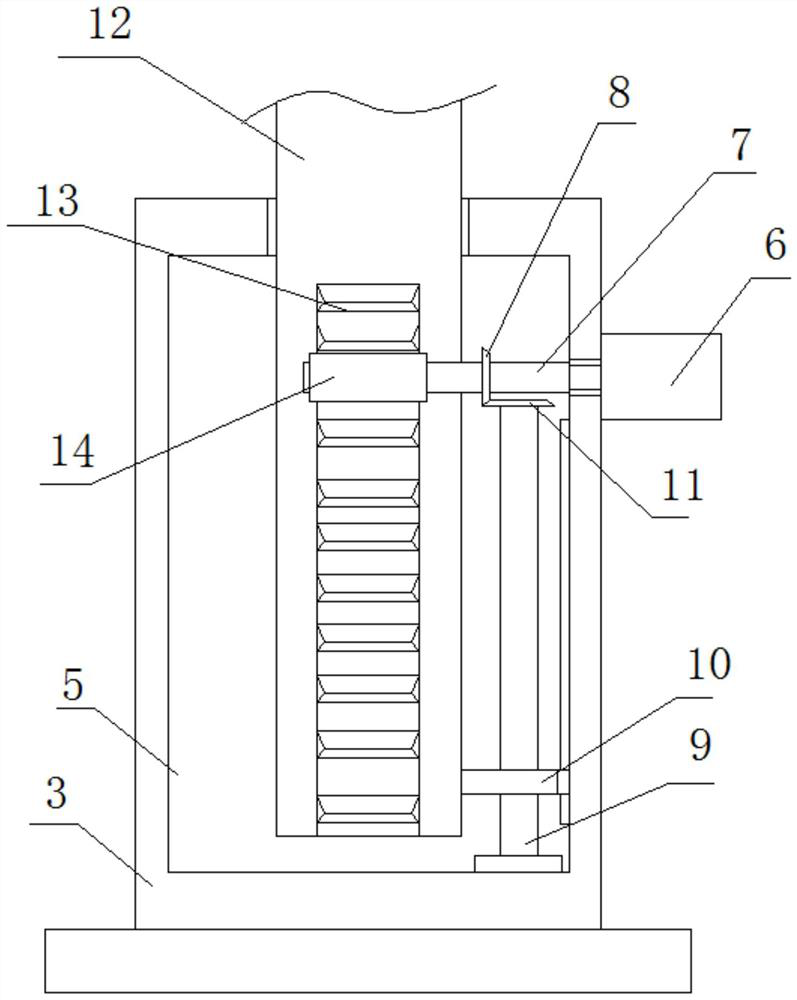

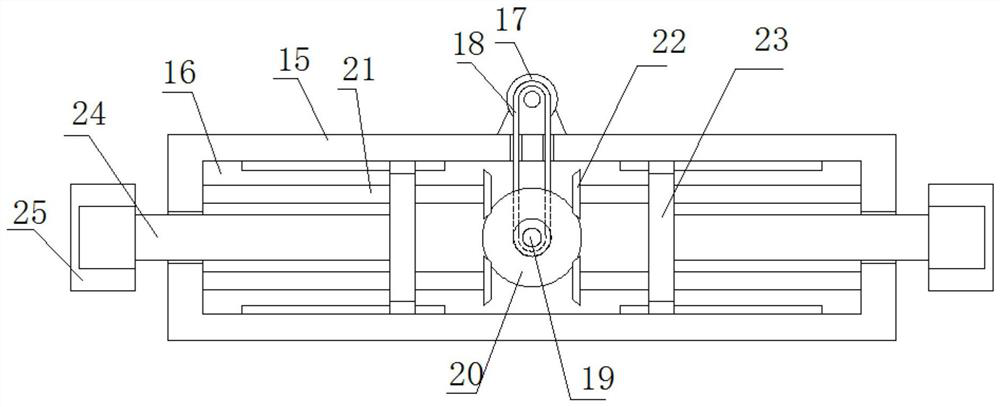

[0028] like Figure 1-5 A prefabricated building buttress stabilization device shown includes a base 1, a lifting block 3 is fixedly installed on the top of the base 1, and a chamber 5 is provided on the lifting block 3, and a chamber 5 is provided on one side of the inner wall of the chamber 5. A vertical plate 12 is slidably installed, and a rack 13 is fixedly installed on one side of the vertical plate 12, and a drive assembly is connected to the rack 13. The top of the vertical plate 12 penetrates the top inner wall of the chamber 5 and extends to the bottom of the lifting block 3. Above, and one side of the vertical plate 12 is fixedly equipped with an adjustment block 15, and the adjustment block 15 is provided with a cavity 16, and two symmetrically arranged screw rods 21 are installed on the inner walls of both sides of the cavity 16, and are located on the same side. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com