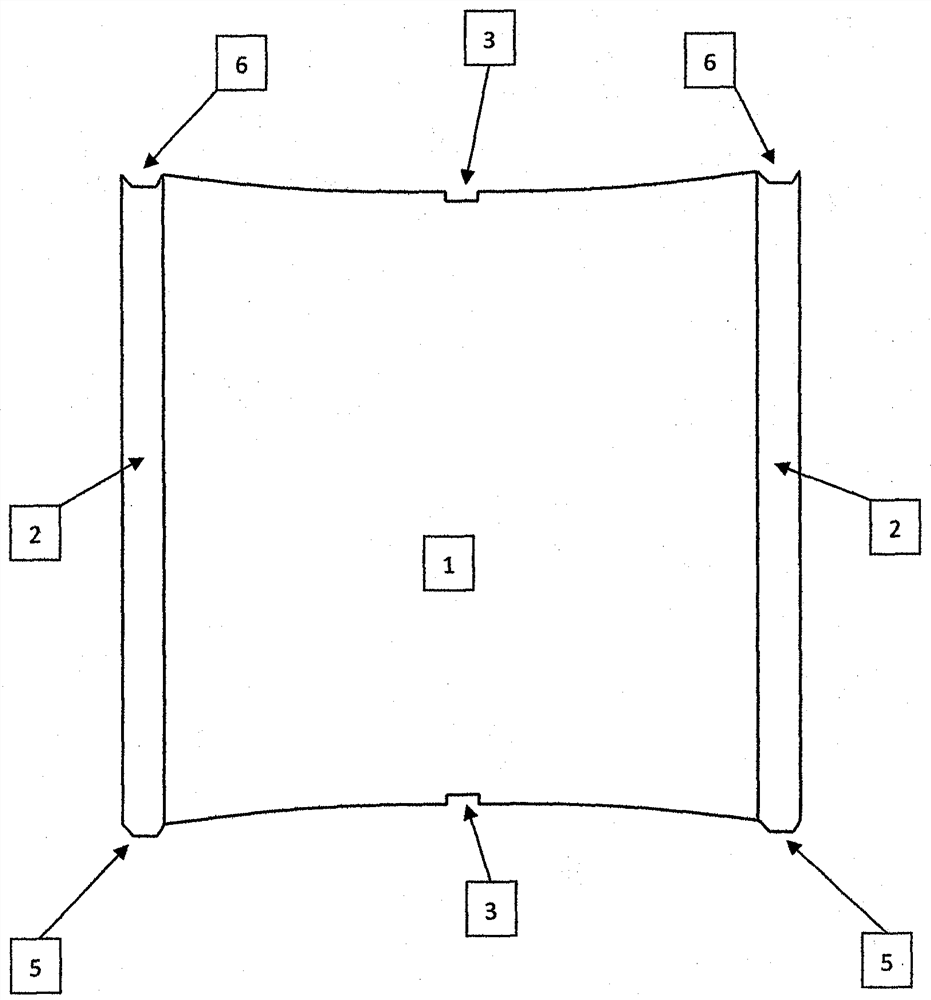

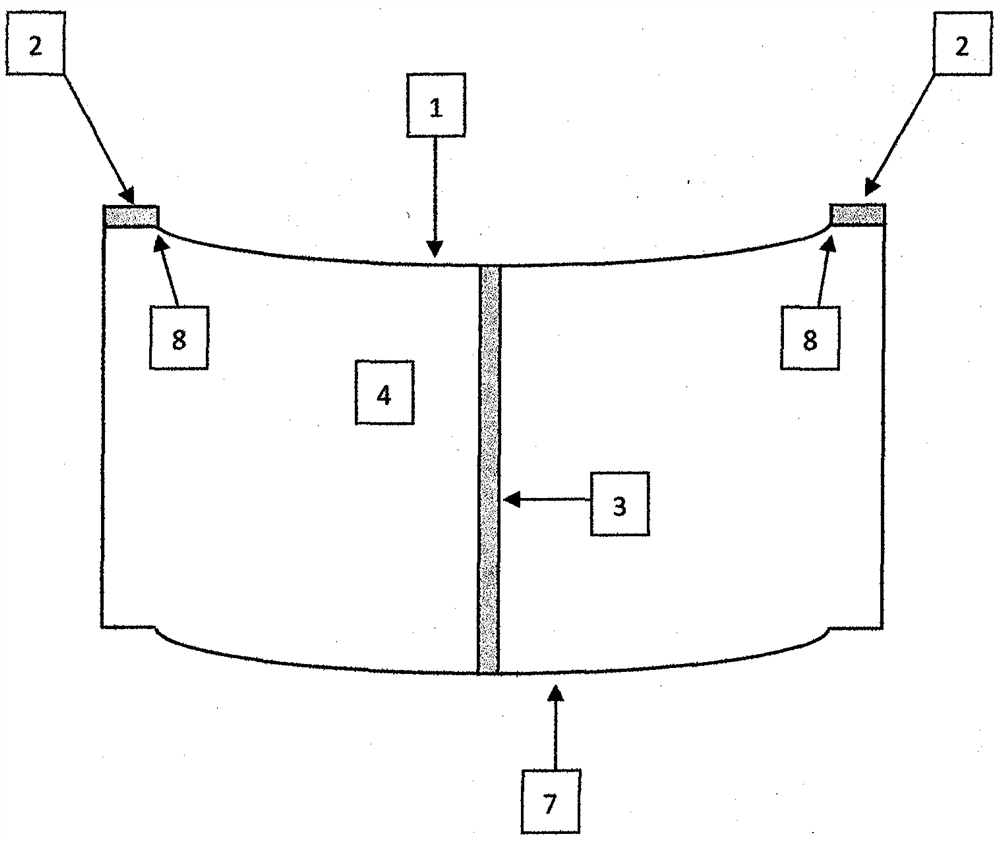

Automatic wall building machine using special wall bricks

A technology of wall bricks and wall-laying machines, which is applied in the processing of building materials, building components, construction, etc., can solve the problems of increasing construction costs, affecting civilized production on the construction site, and wasting building materials, so as to reduce construction costs and save money. Significant benefits and social benefits, the effect of eliminating ash fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is implemented in the following manner:

[0047] 1. Move the automatic wall-laying machine to a suitable position close to the brick wall, adjust the supporting feet of the automatic wall-laying machine, and correct the level of the automatic wall-laying machine;

[0048] 2. Open the PLC system and input the design drawing data of the brick wall;

[0049] 3. Turn on the power;

[0050] 4. Start the positioning and ranging system, measure and locate the wall foundation and the entire wall;

[0051] 5. According to the design requirements, push the ordinary brick storage frame into the reserved position of the automatic wall-laying machine according to the set direction, and trigger the sensor of the brick storage frame;

[0052] 6. According to the design requirements, push the special brick storage frame into the reserved position of the automatic wall-laying machine according to the set direction, and trigger the sensor of the brick storage fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com