Aerator for sewage treatment and treatment method thereof

A technology for sewage treatment and aerator, which is applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Comprehensive aeration, improve the effect of aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

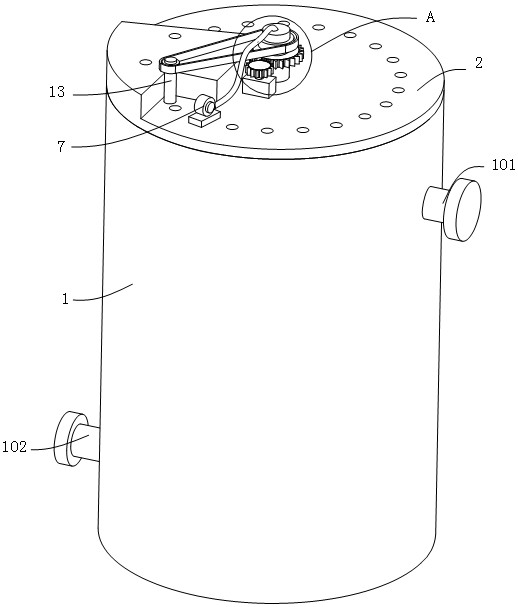

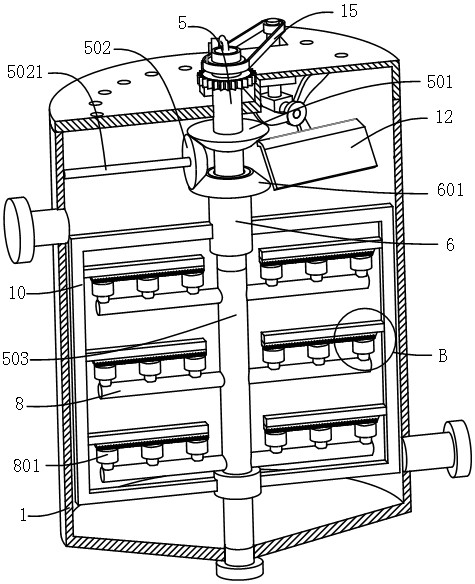

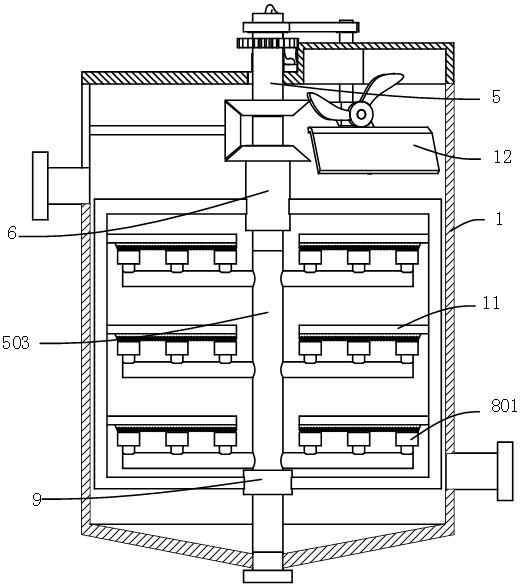

[0039] refer to figure 1 , figure 2 , image 3 and Figure 7 , an aerator for sewage treatment, comprising a body 1 and a machine cover 2, the machine cover 2 is connected to the top of the body 1, the two sides of the outer wall of the body 1 are respectively connected with a water inlet pipe 101 and a water outlet pipe 102, the machine The top of the cover 2 is connected with a motor 3, the output end of the motor 3 is connected with a rotating shaft, the end of the rotating shaft away from the motor 3 is connected with a first gear 301, and the outer wall of the first gear 301 is meshed with a second gear 4, and the center of the cover 2 Rotationally connected with a rotating shaft 5, the second gear 4 is connected to the outer wall of the rotating shaft 5, the outer wall of the rotating shaft 5 is connected with an aeration mechanism, the outer wall of the rotating shaft 5 is connected with a first bevel gear 501, and the outer wall of the first bevel gear 501 is meshed...

Embodiment 2

[0042] refer to Figure 1-4 , an aerator for sewage treatment, which is basically the same as that of Embodiment 1, furthermore, the aeration mechanism includes a blower 7, the blower 7 is connected to the outer wall of the machine cover 2, and the air outlet end of the blower 7 is connected with an exhaust Pipe 701, the end of the exhaust pipe 701 away from the blower 7 is connected to the rotating shaft 5, the rotating shaft 5 is set as a hollow pipe, the bottom of the rotating shaft 5 is connected to the main air pipe 503, and the end of the main air pipe 503 away from the rotating shaft 5 is connected to the fuselage 1, the outer wall of the main air pipe 503 is connected with the air distribution pipe 8, the air distribution pipe 8 communicates with the main air pipe 503, the outer wall of the air distribution pipe 8 is connected with an aeration element 801, and the stirring mechanism includes a fixed ring 9 and two fixed frames 10, two Two fixed mounts 10 are respective...

Embodiment 3

[0045] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , an aerator for sewage treatment, which is basically the same as Embodiment 1, furthermore, the inner wall of the fuselage 1 is connected with a deflector 12, and the inside of the cover 2 is connected with a rotating rod 13, and the rotating rod 13 is connected to the The outer wall of the rotating shaft 5 is connected with a matching synchronous wheel 14, and a synchronous belt 15 is connected between the two synchronous wheels 14. The outer wall of the rotating rod 13 is connected with a box body 16, and the box body 16 is fixedly connected to the inner wall of the fuselage 1 through a connecting plate. , the bottom of the rotating rod 13 is connected with the fourth bevel gear 131, the outer wall of the fourth bevel gear 131 is meshed with the fifth bevel gear 17, the fourth bevel gear 131 and the fifth bevel gear 17 are all rotatably connected in the box body 16, the second The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com