Filling head following lifting mechanism and working method thereof

A lifting mechanism and filling head technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of prolonging filling time and reducing work efficiency, and achieve the effect of improving work efficiency and shortening filling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

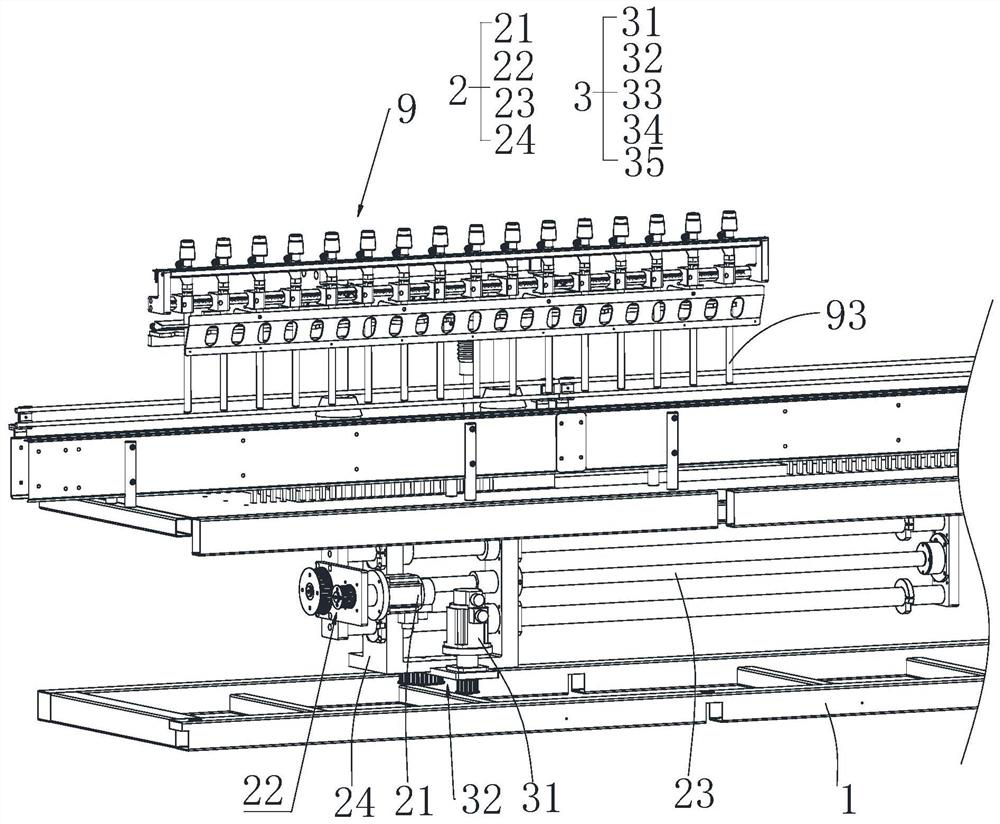

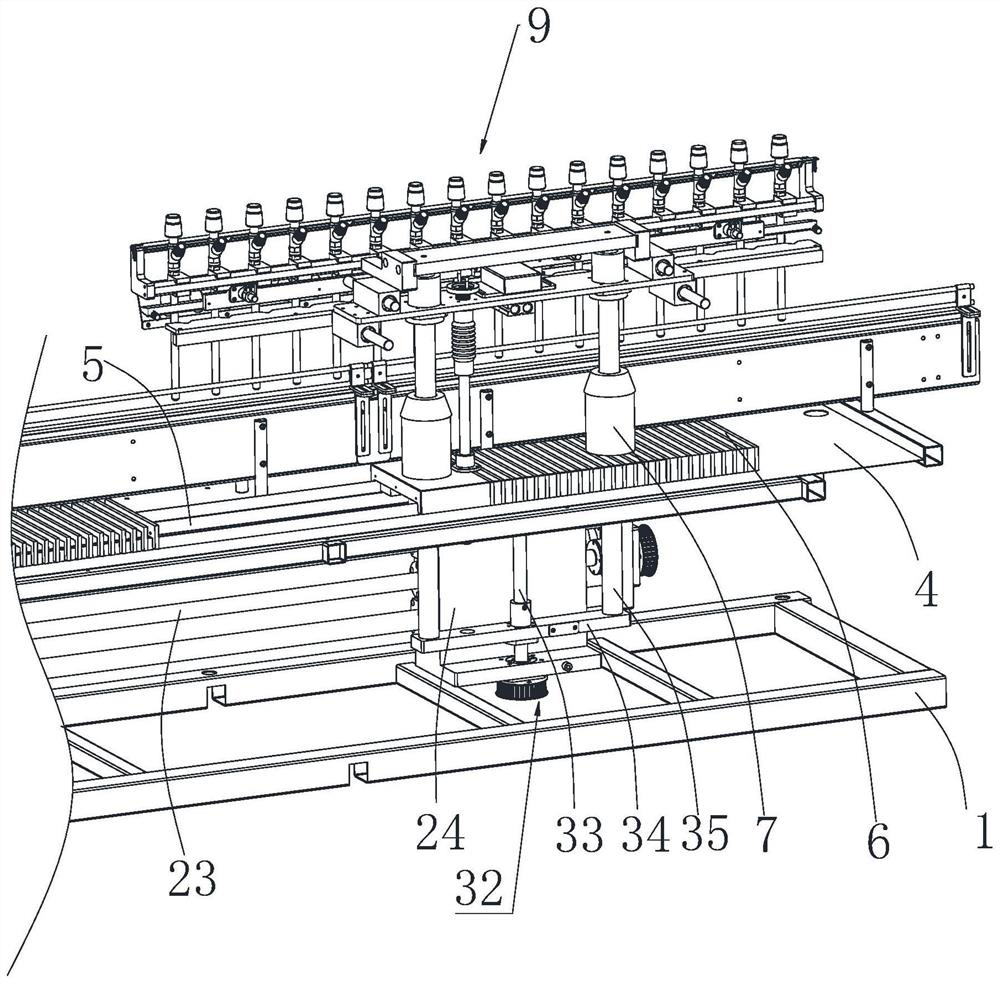

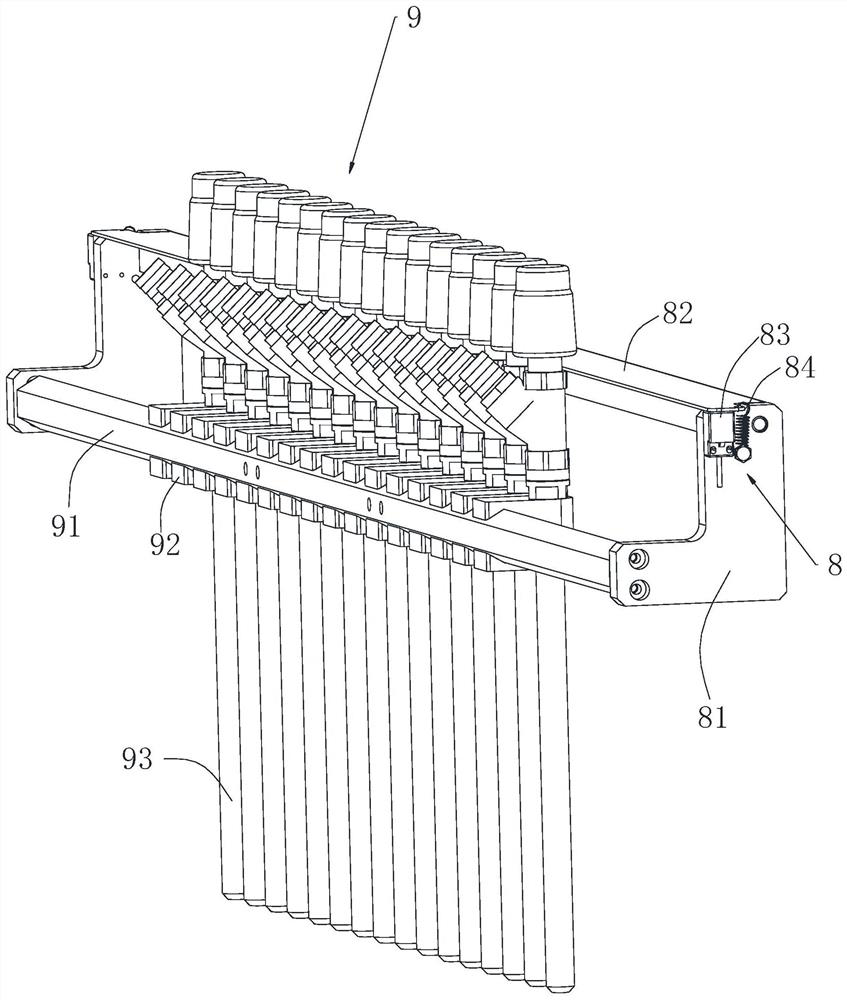

[0024] Such as Figure 1 to Figure 3 As shown, this embodiment provides a filling head following lifting mechanism, including: a support 1 , a traction mechanism 2 disposed on the support 1 , and a lifting mechanism 3 disposed on the traction mechanism 2 . Specifically, the traction mechanism 2 is suitable for driving the lifting mechanism 3 to move synchronously with the packaging material, so that when the lifting mechanism 3 moves, the lifting mechanism 3 is suitable for driving the feeding nozzle mechanism 9 to descend into the packaging material for filling.

[0025] Specifically, in this embodiment, the traction mechanism 2 includes: a first driving member 21 , a first transmission member 22 , a first screw rod 23 and a first moving seat 24 . The first moving seat 24 is screwed on the first screw mandrel 23 , and the lifting mechanism 3 is installed on the first moving seat 24 . When the traction mechanism 2 is in use, start the first driving member 21, drive the first ...

Embodiment 2

[0040] Such as figure 2 As shown, this embodiment provides a working method in which the filling head follows the lifting mechanism, the lifting mechanism 3 is driven by the traction mechanism 2 to follow the packaging material, and while the lifting mechanism 3 is moving, the feeding nozzle is driven by the lifting mechanism 3 Mechanism 9 descends to filling in the packaging material.

[0041] To sum up, while the lifting mechanism 3 is driven by the traction mechanism 2 to move with the packaging material, the lowering nozzle 93 mechanism 9 is driven by the lifting mechanism 3 to drop into the packaging material for filling, thereby realizing the process of conveying the packaging material. Filling can be completed, the packaging material does not need to be stopped, the filling time is shortened, and the work efficiency is improved; the guide sleeve 7 adapted to the guide post 35 is arranged on the installation plate, so that the guide post 35 is more stable when moving up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com