Deformable mechanism driven by memory alloy

A technology of memory alloy and deformation mechanism, which is applied in the direction of fuselage, aircraft parts, transportation and packaging, etc., can solve the problems of unrealizable deformation, affecting the flight mileage of aircraft, and military aircraft without deformable structure, so as to reduce flight resistance and improve The effect of air miles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

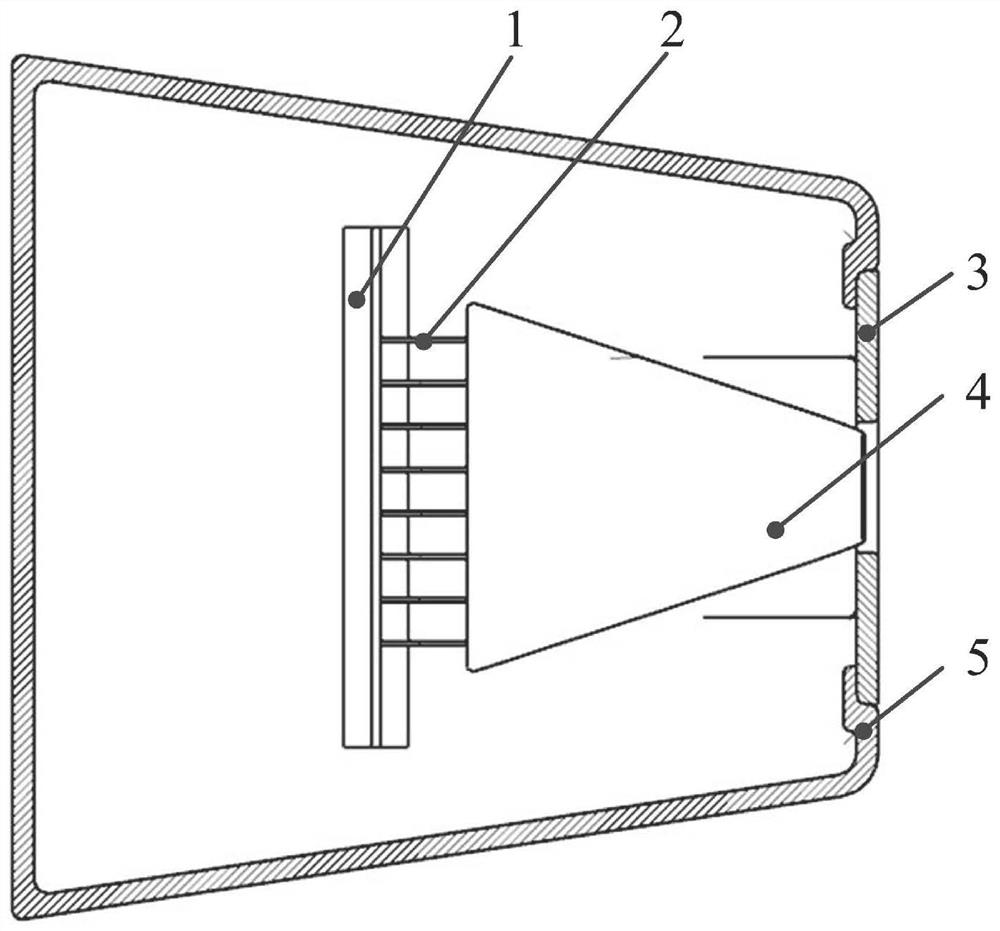

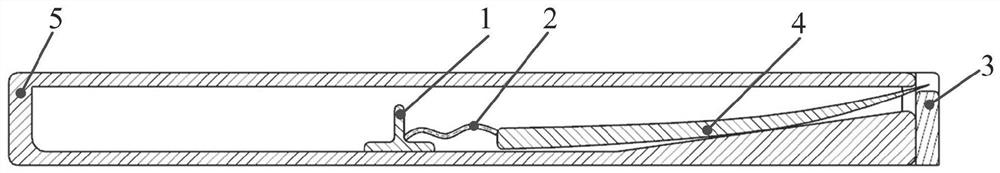

[0016] like figure 1 As shown, a memory alloy driven deformable mechanism of the present invention adopts the technical solution of installing a memory alloy driver 2 and an actuator 4 inside the aircraft shell 5 . The shape memory alloy driver 2 is a shape memory alloy material. After being deformed and fixed, the memory alloy driver 2 realizes the shape memory function by inducing a material phase transformation mechanism through external conditions such as stress or temperature, that is, it can be shaped under high temperature conditions, and its shape can be realized at low temperature or normal temperature. Plastic deformation occurs. During the execution process, the actuator is actuated by means of energization and heating.

[0017] During the flight of the aircraft at a constant speed, the memory alloy driver 2 is actuated, thereby driving the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com