Connecting structure of guide arm and support

A technology for connecting structures and guide arms, which is applied in suspension, cantilever mounted on pivots, transportation and packaging, etc. It can solve the problem of high rigidity of the bracket, easy damage, and large lateral force of the guide arm roll ear, etc. problem, achieve the effect of improving easy loosening and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

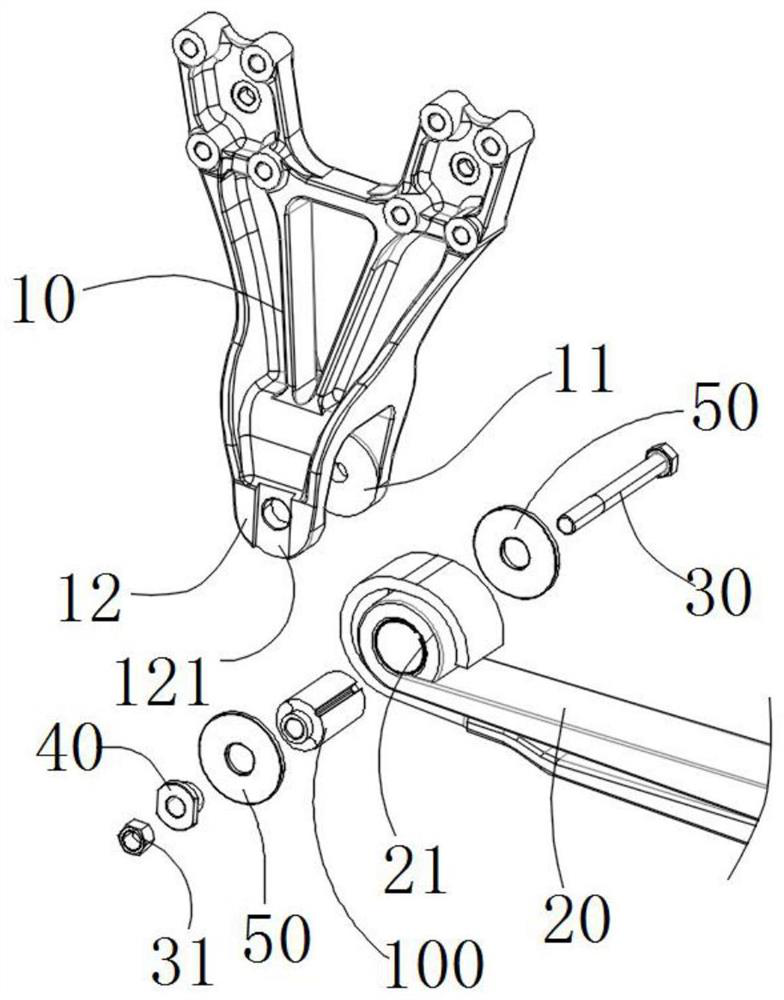

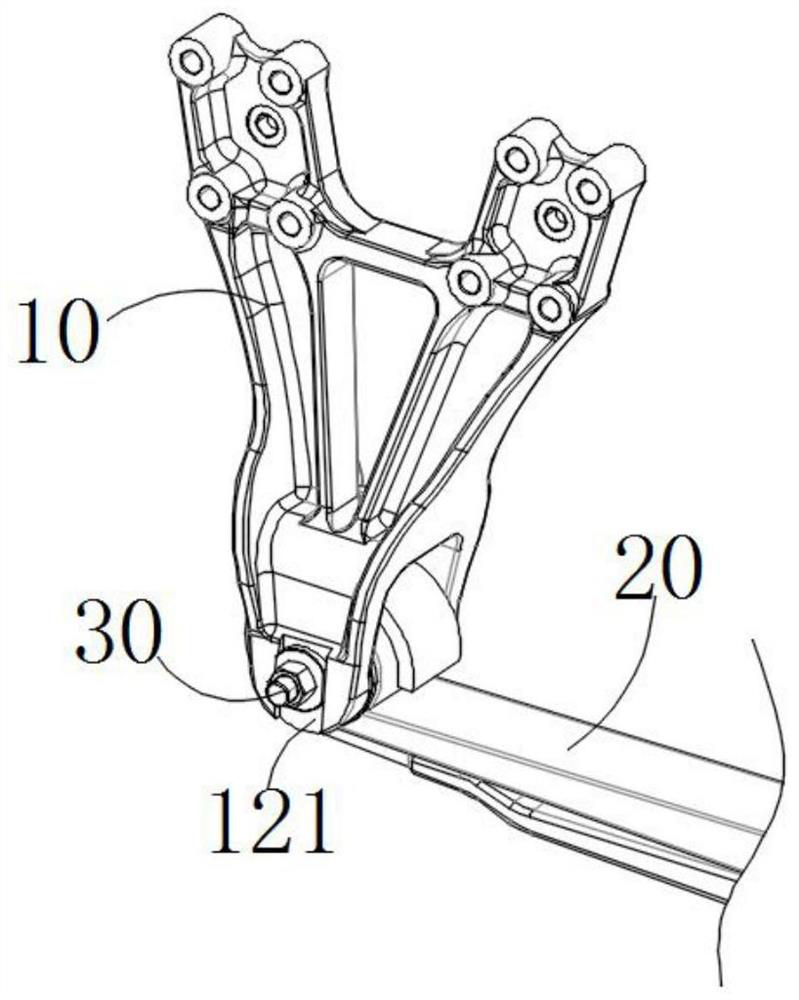

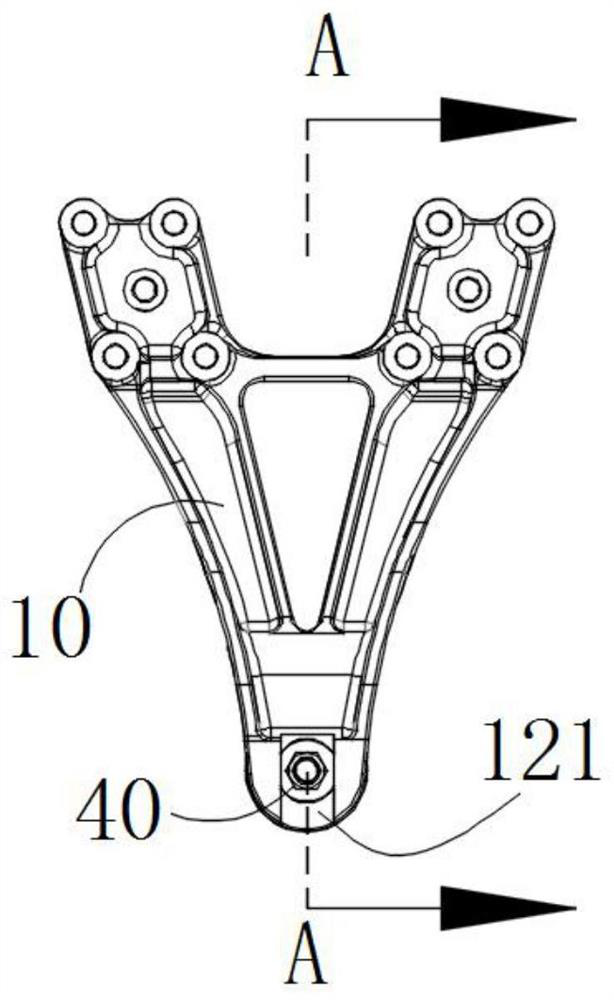

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] This embodiment provides a connection structure between the guide arm and the bracket, see Figure 1-Figure 2 , the composition of this connecting structure includes a bracket 10, a guide arm assembly 20 and a bolt 30 connecting the bracket 10 with the guide arm assembly 20, the bolt 30 will pass through the bracket 10 and the guide arm assembly 20, and be screwed on one side The nut 31 is locked, so that the guide arm assembly 20 is hingedly connected with the bracket 10 .

[0024] Specifically, the bracket 10 includes a first ear seat 11 and a second ear seat 12, and the guide arm assembly 20 includes a rolled ear portion 21; the above-mentioned hinged connection between the guide arm assembly 20 and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com