A pressure line softening process for carton printing

A carton printing and line pressing technology, which is applied in papermaking, paper/cardboard containers, packaging, etc., can solve the problems of not providing rotary guidance for line pressing parts, unable to ensure the accuracy of line pressing operations, and poor softening quality of cardboard, etc. The effect of improving softening quality, increasing heating rate and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

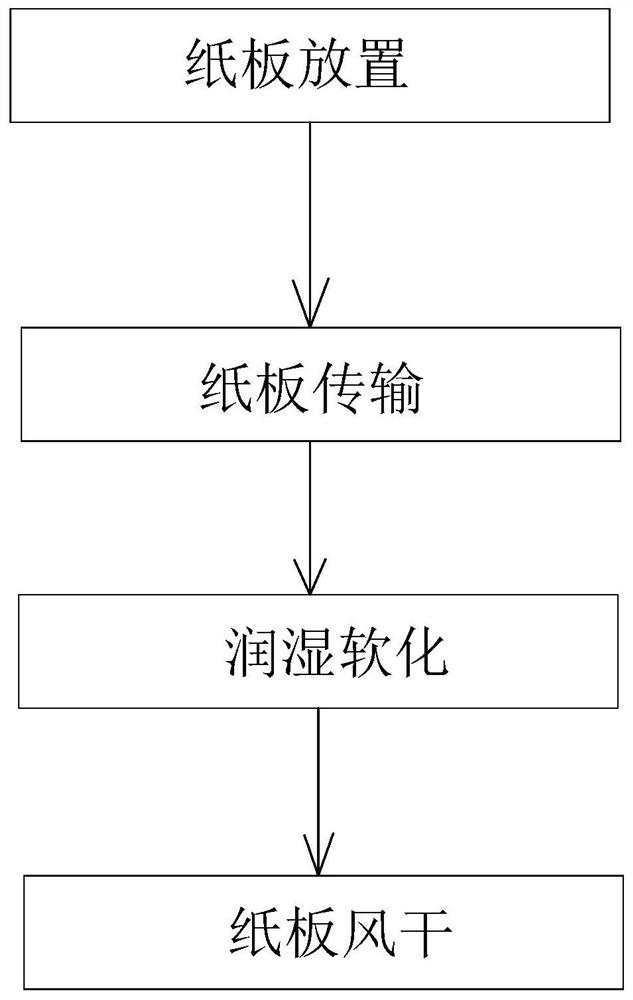

[0031] The creasing softening process for carton printing includes the following steps:

[0032] 1) Place the cardboard for manufacturing the carton;

[0033] 2) The pressing wheel 8 is in contact with the cardboard placed below, and the cardboard is transported along the track of the pressing line;

[0034] 3) While conveying, the nozzle 11 splits and sprays out the softener to wet and soften the cardboard;

[0035] 4) Set the working temperature through the operation panel;

[0036] 5) air-drying, air-drying the cardboard softened by the softener, and controlling the moisture content to 7%-10%.

[0037] The softener includes components in parts by weight: 30-40 parts of water, 6-10 parts of sodium alkylsulfonate, 10-15 parts of sodium alginate, 10-15 parts of acrylic acid, 2-5 parts of oxalic acid, 8-16 parts 10-25 parts of water-based polyurethane, sodium polyacrylate, 5-20 parts of hexanediol, 2-5 parts of sodium stearate; 10-30 parts of sodium hydroxide; 10-30 parts of...

Embodiment 2

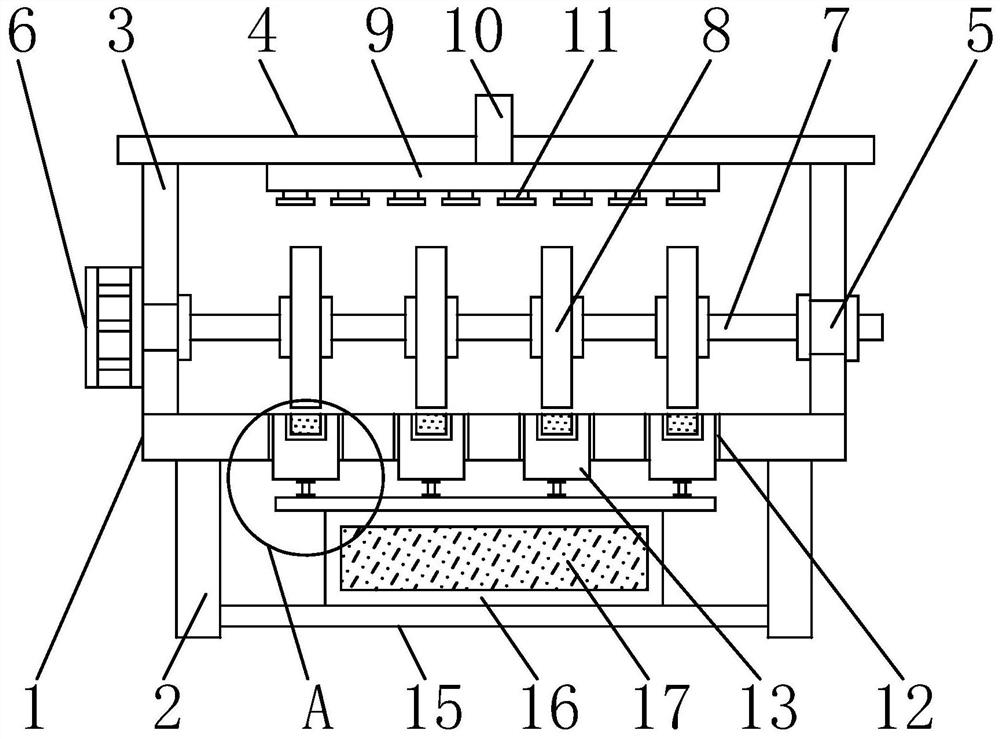

[0047] refer to Figure 3-4, a crimping and softening device for carton printing, comprising a table body 1, vertical columns 2 are fixed vertically around the lower surface of the table body 1, and support plates 3 are welded on both sides of the upper surface of the table body 1, A load plate 4 is fixedly installed between the upper surfaces of the two sets of support plates 3, and a shaft sleeve 5 is welded between the middle positions of the outer walls on both sides of the support plates 3, and one side of the outer walls of the support plates 3 is fixedly installed with A motor 6, and the middle position of the side wall of the motor 6 is vertically and movably connected with a rotating shaft 7, and the outer surface of the rotating shaft 7 is vertically and fixedly sleeved with four sets of pressure rollers 8, and the lower surface of the load plate 4 is fixedly installed with a shaft corresponding to the rotating shaft 7. Divider block 9, and conduit 10 is vertically f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com