A kind of drilling equipment for wooden stool board installation

A wooden bench technology for installation, which is applied to wood processing appliances, manufacturing tools, fixed drilling machines, etc., and can solve problems such as cumbersome movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

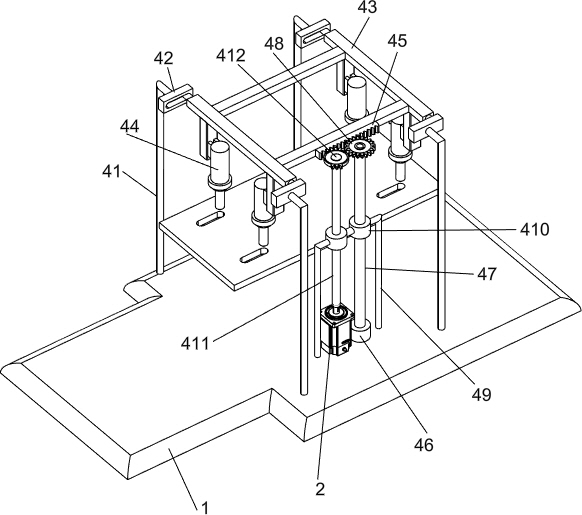

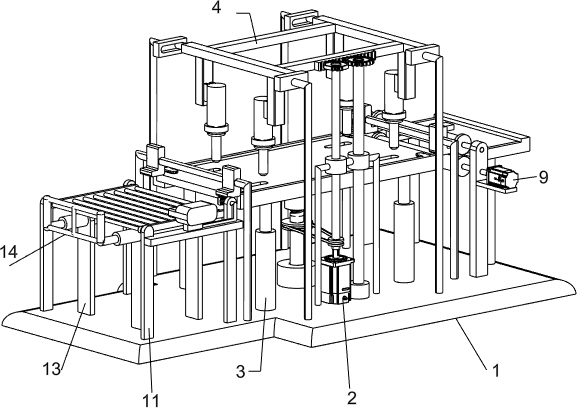

[0023] A kind of drilling equipment for wooden stool board installation, such as Figure 1-6 As shown, it includes a base 1, a servo motor 2, a lifting mechanism 3 and an opening mechanism 4. A servo motor 2 is arranged in the middle of the front side of the top of the base 1, and a lifting mechanism 3 is arranged in the middle of the top of the base 1. The lifting mechanism 3 is located in the servo motor 2 On the rear side, a hole-opening mechanism 4 is provided in the middle of the top of the base 1 , and the hole-opening mechanism 4 is located directly above the lifting mechanism 3 .

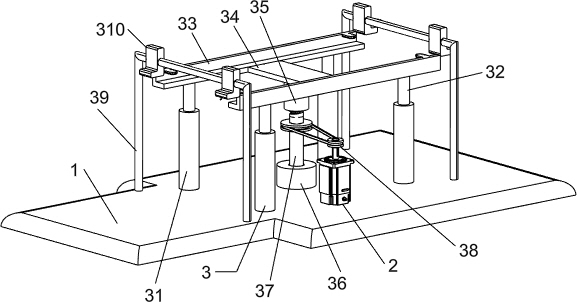

[0024] The lifting mechanism 3 includes a first sliding sleeve 31, a sliding rod 32, a first support frame 33, a connecting plate 34, a threaded sleeve 35, a first bearing seat 36, a threaded rod 37, a belt transmission assembly 38, a fixed rod 39 and a fixed block 310, first sliding sleeves 31 are symmetrically arranged on both front and rear sides of the top of the base 1, the first slidin...

Embodiment 2

[0030] On the basis of Example 1, as figure 1 and Figure 4-6 As shown, it also includes a mounting plate 5, a third rotating shaft 6, a rubber roller 7, a second full gear 8, a deceleration motor 9 and a second supporting frame 10. The right side of the top of the base 1 is symmetrically provided with a mounting plate 5 front and rear, on both sides The mounting plate 5 is located on the right side of the first support frame 33 , a third rotating shaft 6 is arranged symmetrically up and down between the two mounting plates 5 , the third rotating shaft 6 on both sides is located between the upper parts of the two mounting plates 5 , and the third rotating shaft on both sides is 6 are provided with rubber rollers 7, the rear ends of the third rotating shafts 6 on both sides are provided with second full gears 8, the two second full gears 8 are meshed with each other, and the upper part of the front side of the front mounting plate 5 is provided with a reduction motor 9, which r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com