Frame drilling feeding device

A frame and frame technology, which is applied in the field of frame drilling and feeding devices, can solve the problems of high labor intensity and reduced drilling efficiency of structural parts, and achieve the effects of reducing labor intensity and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

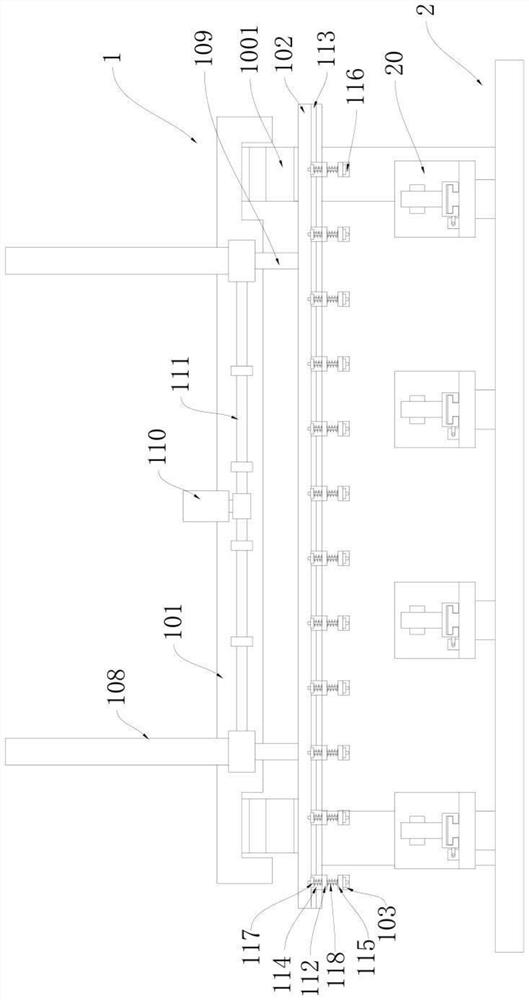

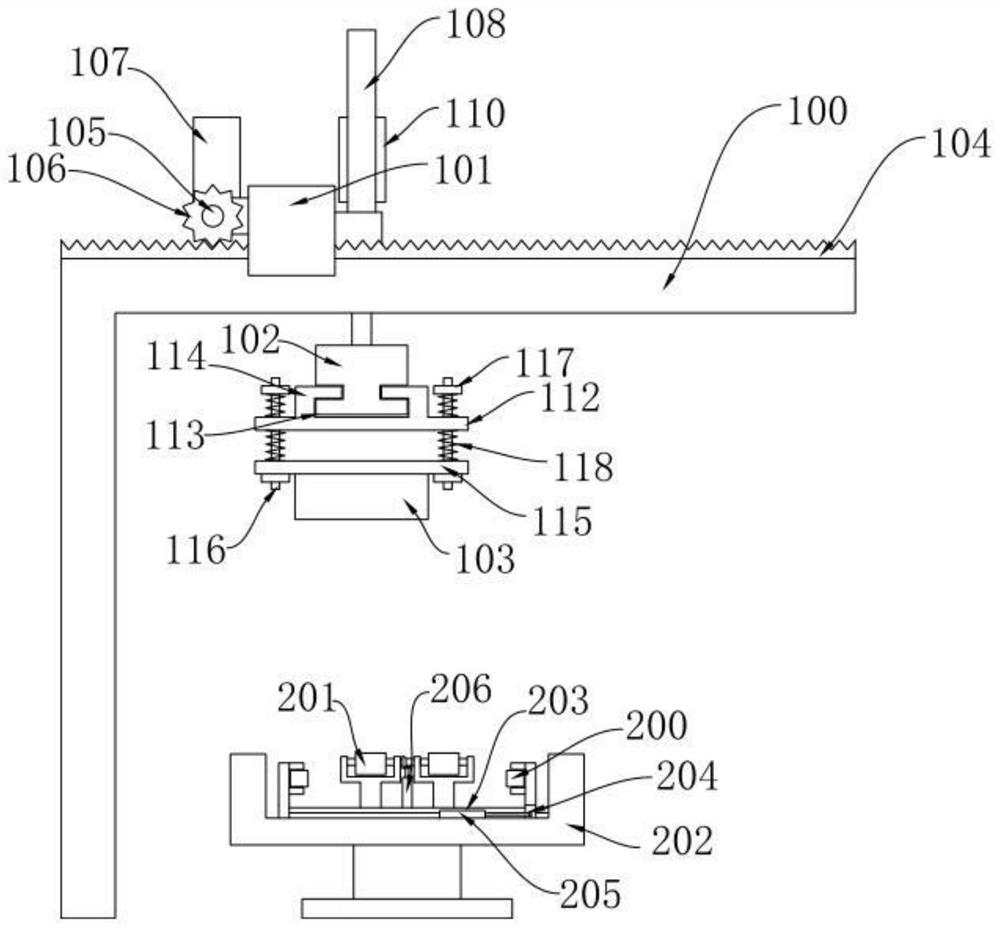

[0026] like figure 1 , figure 2 As shown in the figure, a frame drilling and feeding device provided by the present invention includes a feeding assembly 1 and a fixing assembly 2. The feeding assembly 1 is mainly used to realize automatic feeding of structural parts, and the fixing assembly 2 is mainly used to complete the The loaded structural parts are fixed or sent out, so that the structural parts are directly transported to the next process after being fixed and drilling is completed.

[0027] The loading assembly 1 includes a frame 100, a beam 101 that can move along the Y-axis on the frame 100, and a fixed beam 102 that can move along the Z-axis on the beam 101. The fixed beam 102 is provided with a plurality of electromagnetic Iron 103, a plurality of electromagnets 103 are evenly spaced along the axis direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com