Compact type double-tooth anti-backlash mechanical single pendulum head

A compact, single-swing head technology, used in metal processing mechanical parts, large fixed members, milling machine equipment, etc., can solve the problems of large torque and small enough volume, eliminate backlash, reduce overall dimensions, and reduce overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

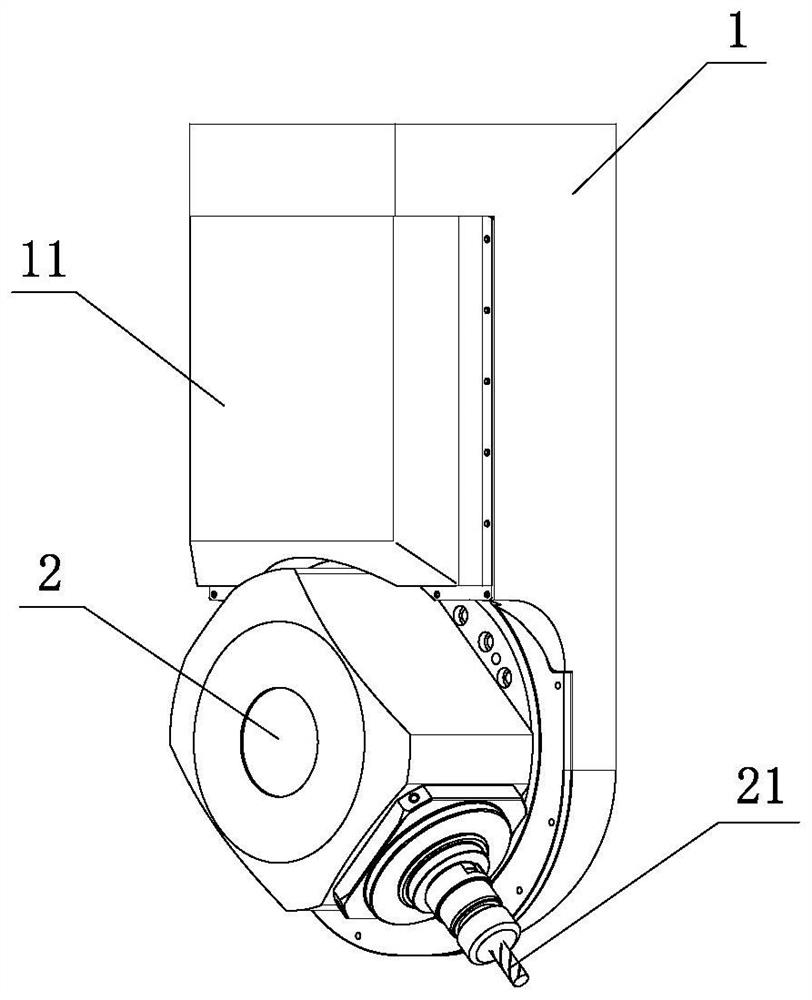

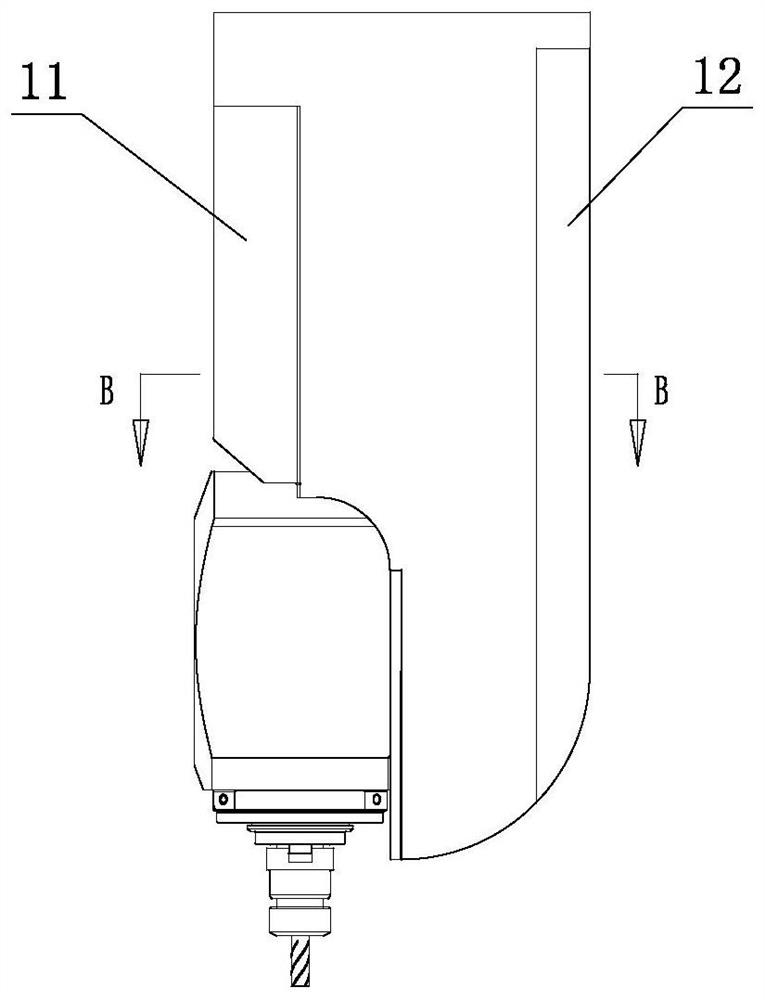

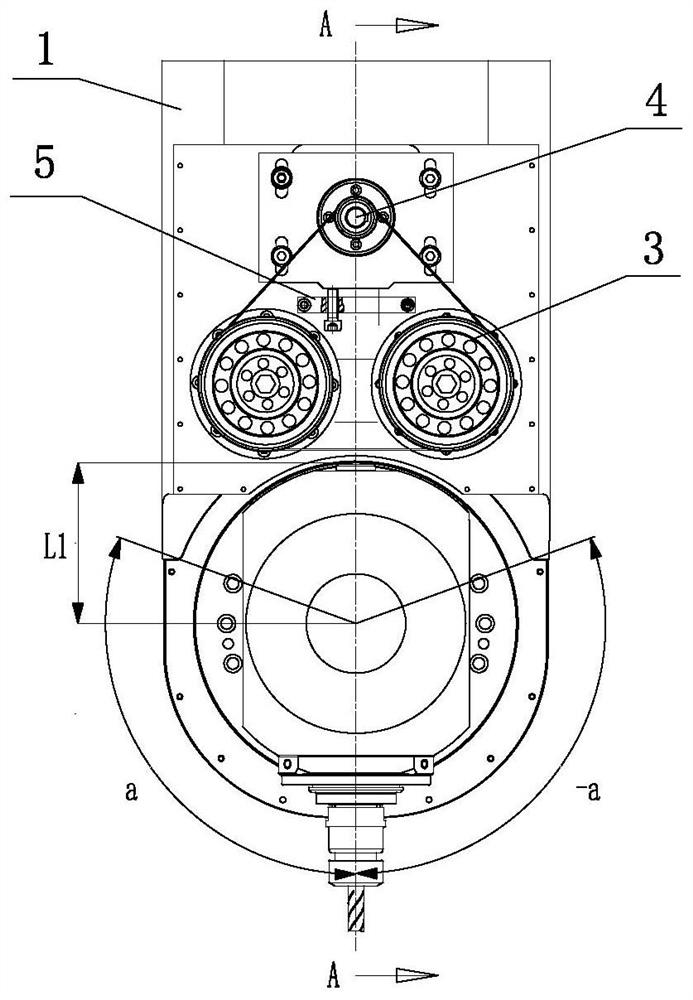

[0037] Such as Figure 1-14 As shown, a compact dual-tooth anti-backlash mechanical single swing head includes a box body 1, a main shaft 2, a transmission mechanism 3 and a driving device 4. Drive device 4 selects motor 41 for use, specifically can select servo motor for use, can make control speed and position accuracy very accurate, is provided with motor mounting hole 14 on the casing 1, and the rear end (output end of motor) of motor mounting hole 14 is provided with motor The mounting plate 42 is used for mounting and positioning the motor 41 . The transmission mechanism 3 and the driving motor are all located in the casing 1, and the casing 1 is provided with a front protective case 11 and a rear protective case 12, and each component in the casing 1 is protected by the front protective case 11 and the rear protective case 12. Transmission mechanism 3 comprises driving pulley 31, synchronous belt 32, driven pulley 33, speed reducer 34, driving gear 35 and driven gear 3...

Embodiment 2

[0049] Such as Figure 15-16 As shown, the difference from Embodiment 1 is that the rollers 51 on the first connecting rod 52 and the second connecting rod 53 are all arranged on the inside of the synchronous belt 32, the spring 54 is always in a compressed state, and the two ends of the spring 54 produce The elastic force makes the first connecting rod 52 and the second connecting rod 53 open along the pivot 55, and the rollers 51 on the first connecting rod 52 and the second connecting rod 53 will support the synchronous belt 32, so that the synchronous belt 32 is in the Tension state, to ensure normal transmission. If the synchronous belt 32 slacks after working for a period of time, the position of the spring 54 can be manually adjusted regularly (the adjustment principle is the same as in embodiment 1), that is, the two ends of the spring 54 are connected with the distance adjustment hole 56 farther away from the pivot 55 to Increase the tension of the synchronous belt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com