Reinforced joint clutch for heavy-load motor tricycle

A three-wheeled motorcycle and clutch technology, applied in friction clutches, clutches, mechanical drive clutches, etc., can solve the problems of the failure of the outer spline of the center sleeve, the large clutch operating force value, and the limited volume of the clutch, so as to increase the service life, The effect of increasing the output torque and improving the coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

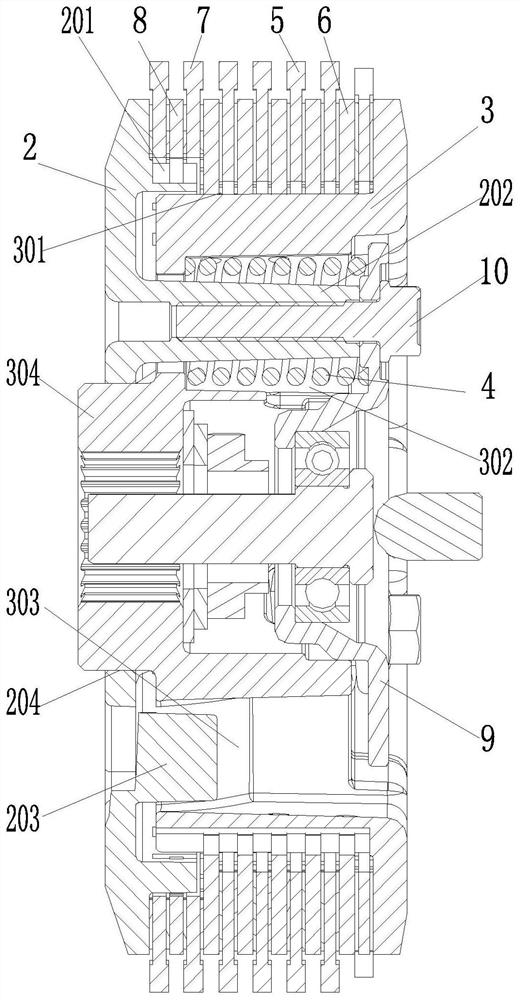

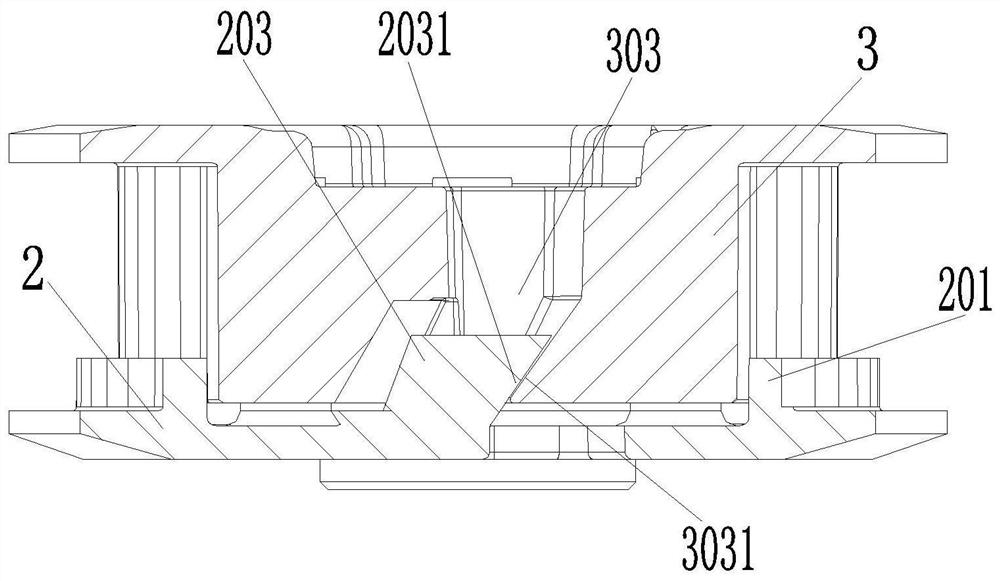

[0024] As shown in the figure, the reinforced engagement clutch for a heavy-duty three-wheeled motorcycle in this embodiment includes a pressure plate 2, a friction plate assembly, and a center sleeve 3; Rotation clearance, the pressure plate and the center sleeve are also meshed through the inclined plane meshing pair; when the clutch is engaged for transmission, the pressure plate has relative rotation relative to the center sleeve in the transmission direction, and the inclined plane meshing pair produces Axial component force that draws the pressure plate closer to the center sleeve;

[0025]There is a clearance for relative rotation in the circumferential direction between the pressing plate 2 and the center sleeve 3, and the clearance for relative rotation in the circumferential direction between the pressing plate 2 and the central sleeve 3 can be designed on the basis of the cooperative relationship between the two. The usual design is that the two are approximately sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com