An automatic telescopic anti-blocking flushing device for shield machine cutter head

An automatic retractable and flushing device technology, which is applied in mining equipment, tunnels, earthwork drilling, etc., can solve the problems of unprotected flushing nozzles, blockage of flushing nozzles, and failure of flushing effect, etc., and achieves compact structure design, good sealing performance, and improved reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

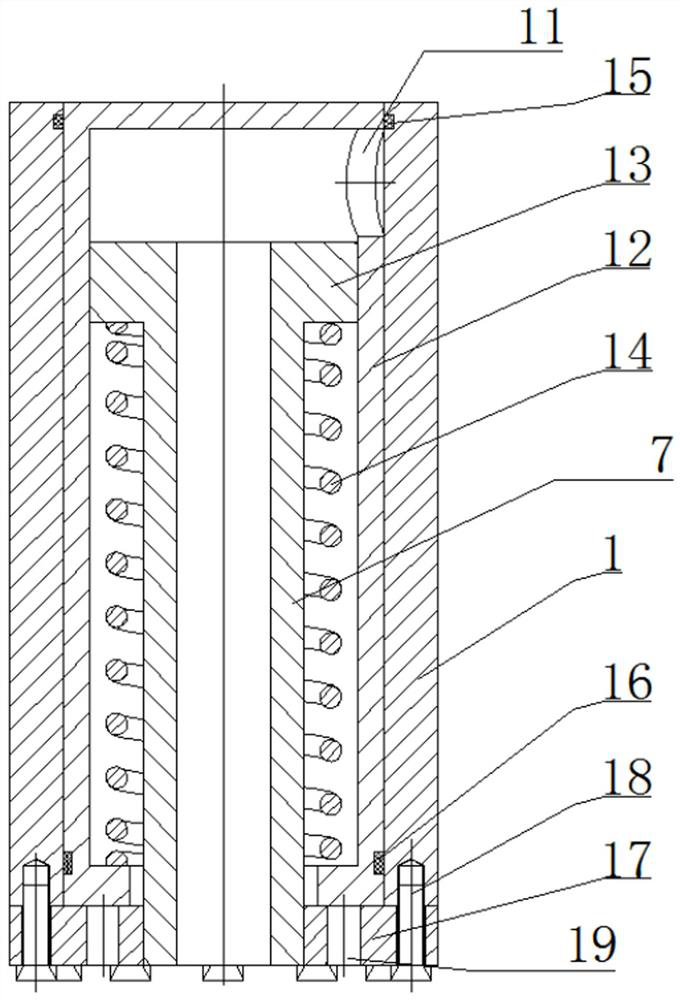

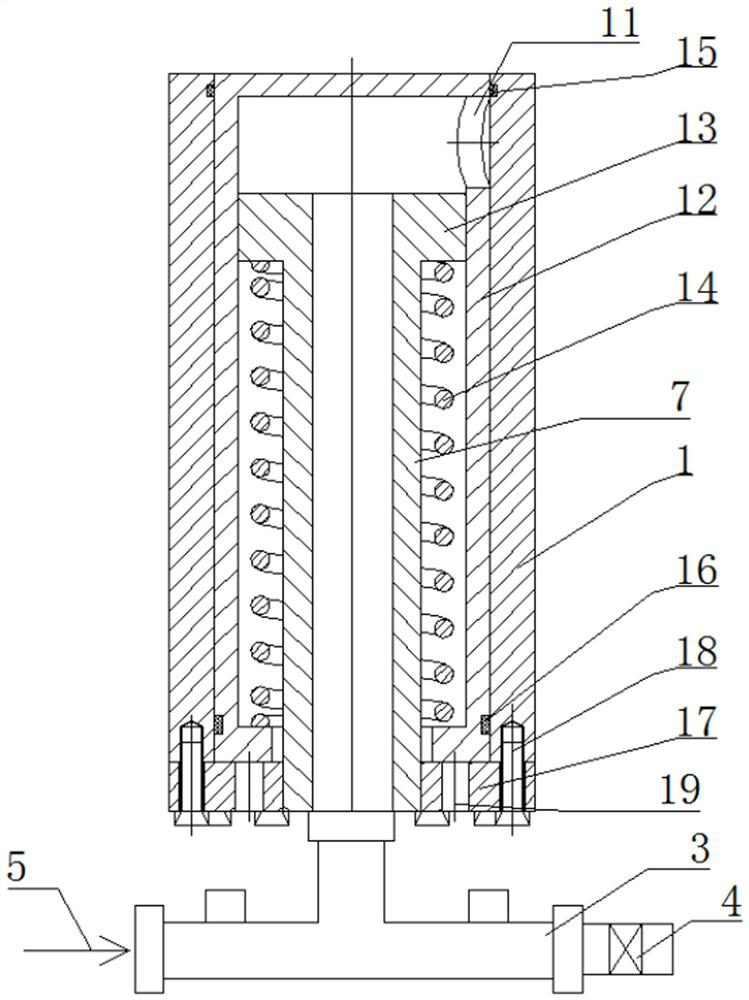

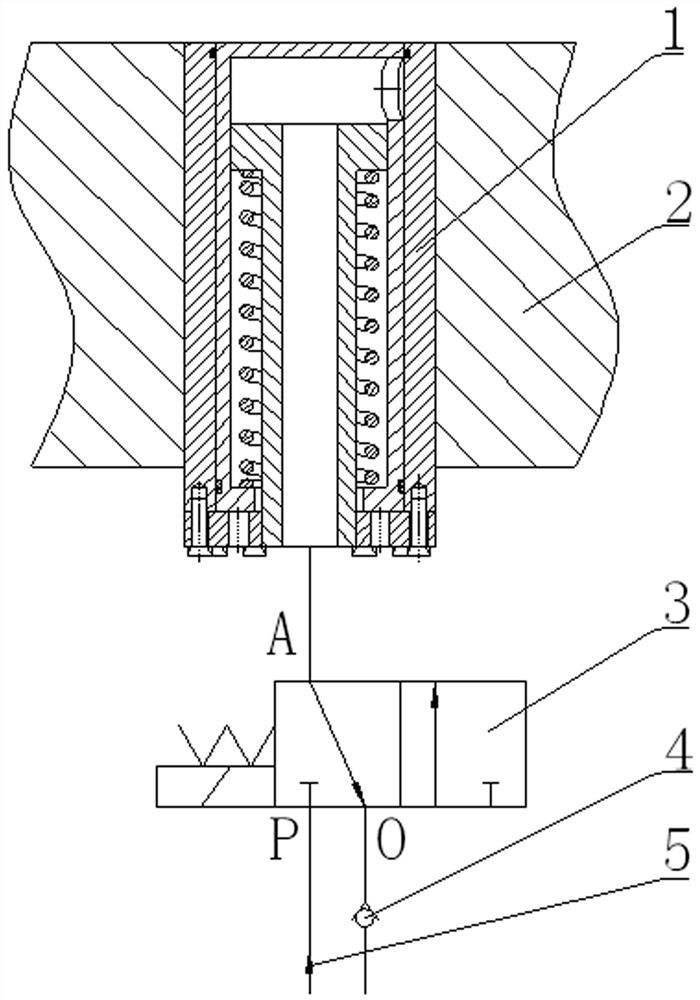

[0031] An automatic telescopic anti-blocking flushing device for the cutter head of a shield machine, such as Figure 1 to Figure 4 , including a fixed sleeve 1 installed on the cutterhead panel 2;

[0032] A cylindrical anti-clogging nozzle 12 is slidably set in the fixed sleeve 1, and the top of the anti-clogging nozzle 12 is closed, and a water spout 11 is provided on the side wall of the anti-clogging nozzle 12 near its top surface; 12 cooperates with the inner wall of the fixed sleeve 1, so that a piston structure is formed between the two, so that the water nozzle 11 of the anti-blocking nozzle 12 is exposed to the fixed sleeve 1 to flush the cutter head panel 2, or is hidden in the fixed sleeve 1 , to prevent the earth from blocking the water spout 11 when the shield machine is excavated.

[0033] A hollow guide rod 7 is provided in the anti-blocking nozzle 12, and the front end side wall of the guide rod 7 is provided with a limit end 13, the limit end 13 can prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com