Method for building artificial island and pile foundation bearing platform workbench through waste boxing and stacking

A technology for artificial islands and workbenches, applied in artificial islands, buildings, sheet pile walls, etc., can solve the problems of time-consuming, uneconomical, heavy workload, and river pollution, etc., to reduce workload, improve efficiency, and achieve economical Benefit Social benefits and environmental benefits with obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

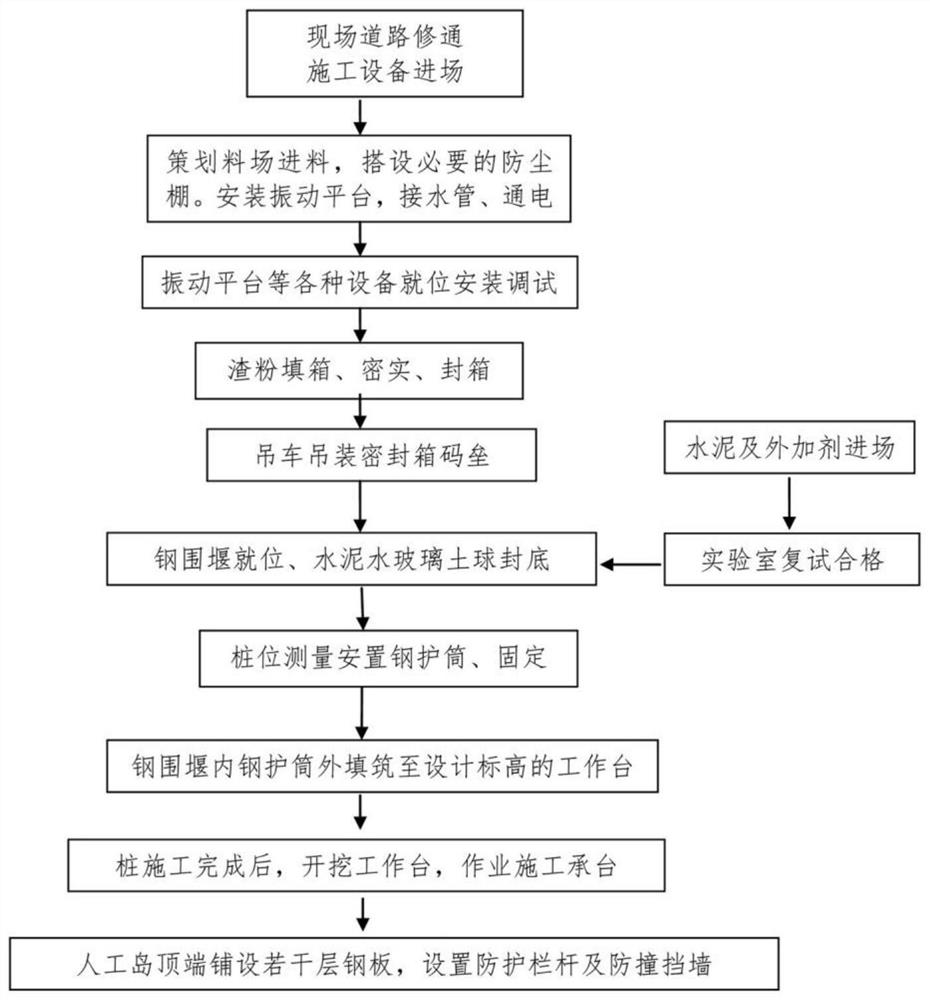

[0023] Such as Figure 1 to Figure 7 Shown is a method for building an artificial island and a pile cap platform with waste packing piles, which is characterized in that it includes the following steps:

[0024] ① Fill the garbage slag powder into the sealed box, and use the vibrating table to vibrate it tightly after filling to form a permanent airtight box;

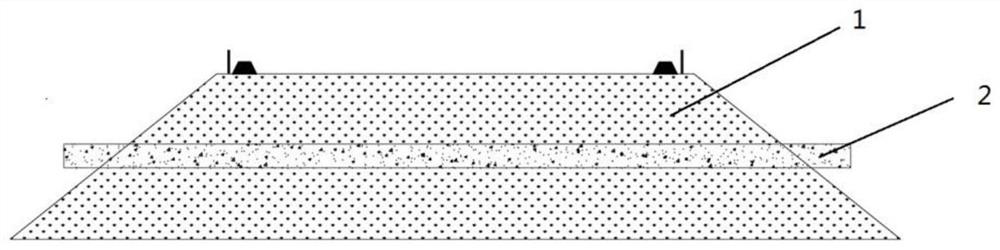

[0025] ②Using a crane to hoist the sealed box into the water in a step-like pile to form an artificial island 1, the lower part of the artificial island 1 is preset with several water pipes 2 for upstream water to flow through the lower part of the artificial island 1;

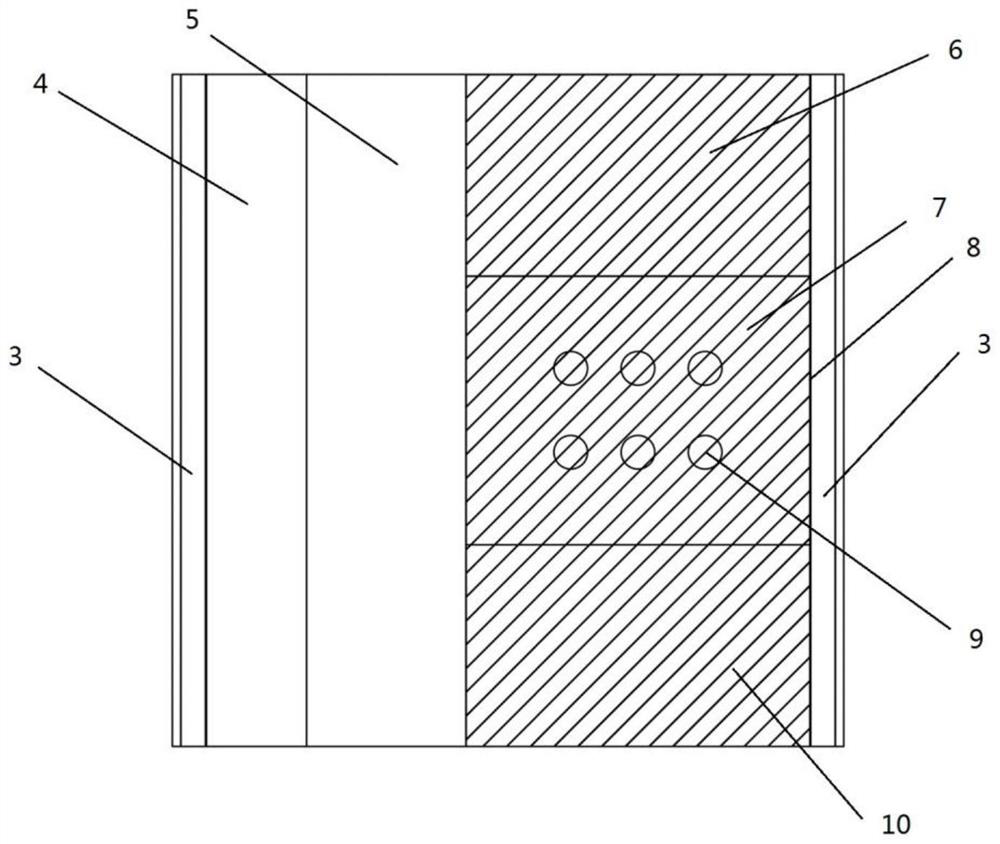

[0026] ③ Fixing the steel cofferdam 8 at a preset position, and building up the artificial island 1 through the sealing box around the outer wall of the steel cofferdam 8;

[0027] ④ The steel cofferdam 8 needs to be sealed at the bottom to ensure its dry operation after pumping, and the bottom cover is made of cement water glass earth balls;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com