Compound bentonite raw material for seawater drilling fluid as well as preparation method and application thereof

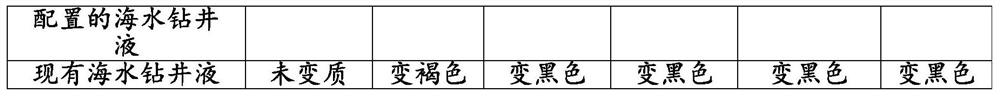

A technology of drilling fluid and bentonite, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of easy fermentation, increased cost of drilling or directional drilling, blackening and odor, etc., and achieve the effect of slow fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

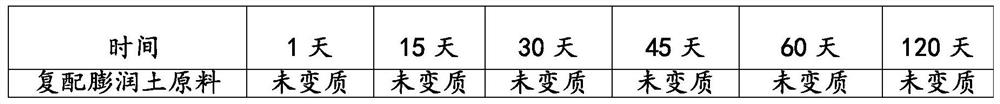

Examples

Embodiment 1

[0031] This embodiment provides a compound bentonite raw material for seawater drilling fluid, which consists of the following components in parts by weight:

[0032] Sodium bentonite: 1000 parts; anionic cellulose: 38 parts; sodium carbonate: 18 parts; xanthan gum: 8 parts; HM-modified polymer fluid loss additive: 8 parts; guar gum: 6 parts; polypropylene Amide: 0.3 part and copper sulfate: 0.08 part.

[0033] This embodiment also provides a method for preparing a compound bentonite raw material for seawater drilling fluid, comprising the following steps:

[0034] Get raw materials according to the following parts by weight: 1000 parts; Anionic cellulose: 38 parts; Sodium carbonate: 18 parts; Xanthan gum: 8 parts; HM-modified polymer fluid loss reducer: 8 parts; Guar gum: 6 parts part; polyacrylamide: 0.3 part and copper sulfate: 0.08 part, stir and mix evenly to obtain the composite bentonite raw material for seawater drilling fluid.

[0035] Among them, anionic cellulose ...

Embodiment 2

[0042] This embodiment provides a compound bentonite raw material for seawater drilling fluid, which consists of the following components in parts by weight:

[0043] Sodium bentonite: 1000 parts; anionic cellulose: 42 parts; sodium carbonate: 22 parts; xanthan gum: 12 parts; HM-modified polymer fluid loss control agent: 12 parts; guar gum: 10 parts; polypropylene Amide: 0.5 part and copper sulfate: 0.12 part.

[0044] This embodiment also provides a method for preparing a compound bentonite raw material for seawater drilling fluid, comprising the following steps:

[0045] Get raw materials according to the following parts by weight: sodium bentonite: 1000 parts; anionic cellulose: 42 parts; sodium carbonate: 22 parts; xanthan gum: 12 parts; HM-modified polymer fluid loss reducer: 12 parts; Seoul gum: 10 parts; polyacrylamide: 0.5 parts and copper sulfate: 0.12 parts, stirred and mixed evenly to obtain the compound bentonite raw material for seawater drilling fluid.

[0046]...

Embodiment 3

[0053] This embodiment provides a compound bentonite raw material for seawater drilling fluid, which consists of the following components in parts by weight:

[0054] Sodium bentonite: 1000 parts; anionic cellulose: 40 parts; sodium carbonate: 20 parts; xanthan gum: 10 parts; HM-modified polymer fluid loss additive: 10 parts; guar gum: 8 parts; polypropylene Amide: 0.4 part and copper sulfate: 0.1 part.

[0055] This embodiment also provides a method for preparing a compound bentonite raw material for seawater drilling fluid, comprising the following steps:

[0056] The raw materials are taken according to the following parts by weight: sodium bentonite: 1000 parts; anionic cellulose: 40 parts; sodium carbonate: 20 parts; xanthan gum: 10 parts; HM-modified polymer fluid loss reducer: 10 parts; Seoul gum: 8 parts; polyacrylamide: 0.4 part and copper sulfate: 0.1 part, stirred and mixed evenly to obtain the compound bentonite raw material for seawater drilling fluid.

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com