A crystallization treatment method for improving the product quality of mesotrione

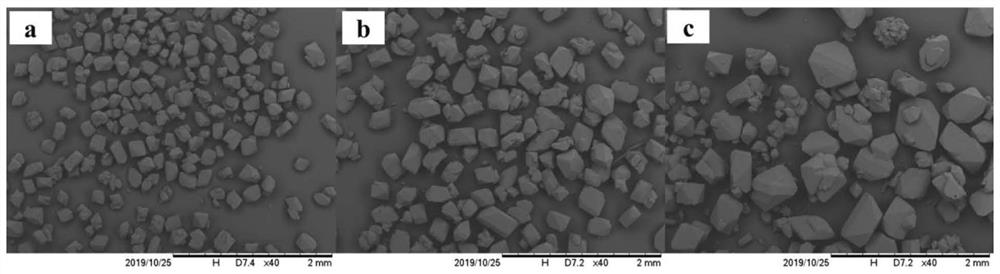

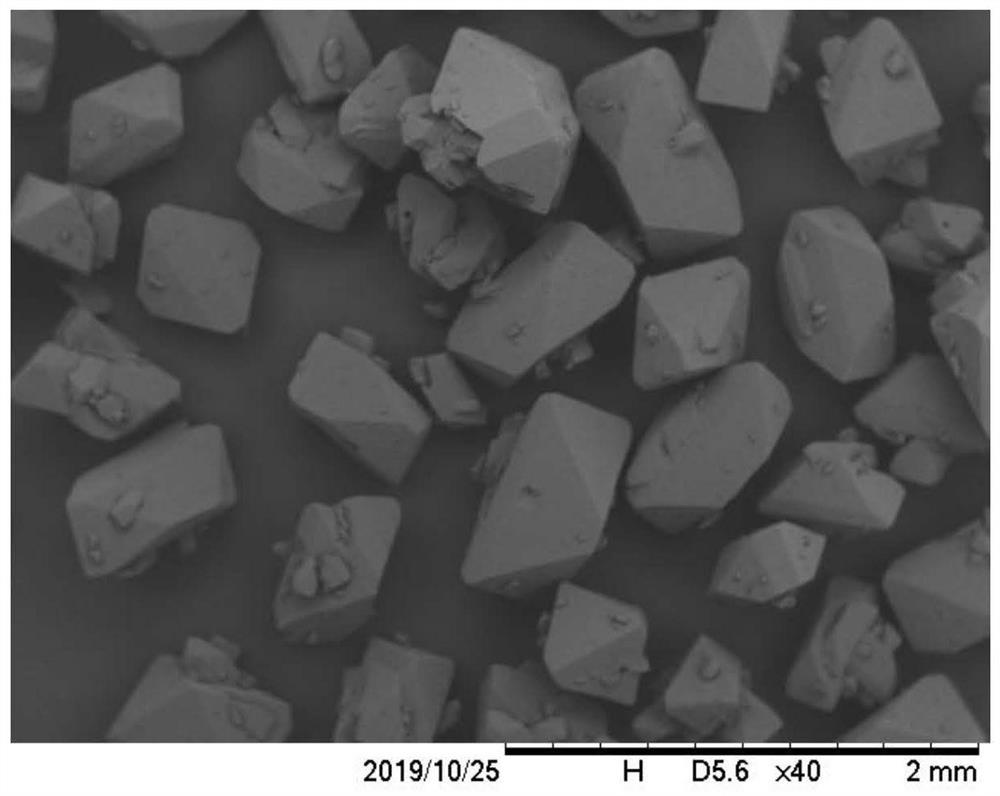

A technology for mesotrione and crystallization treatment, applied in the directions of organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of increased production costs, low fluidity of powder products, and increased bulk density, etc. The effect of improving bulk density, large particle size and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1, seed crystal preparation process:

[0049] 1) Take 16g of the powder raw material product and add it to a 250mL crystallizer filled with 100g of dichloroethane solvent;

[0050] 2) Warm up to 55°C to dissolve the liquid, and the stirring speed is 250rpm;

[0051] 3) Cool down to 15°C at a uniform speed within 120 minutes;

[0052] 4) Cultivate crystals at a constant temperature for 5 hours at 15°C, filter, and dry to obtain 9.8 g of seed crystals;

[0053] Step 2, crystallization process strengthening:

[0054] 1) Take 340gm of organic mother liquor (mass concentration is about 0.16), add 5.1g of acidic activated carbon powder, and stir for 60min in an oil bath at 55°C at a stirring speed of 250rpm;

[0055] 2) Use a preheated round-bottomed flask and funnel to filter the decolorized mother liquor, quickly place the filtered mother liquor in a crystallizer whose temperature is controlled by an ice machine at 55°C, and program to cool down to 45°C within 60 mi...

Embodiment 2

[0063] Step 1, seed crystal preparation process:

[0064] 1) Take 14g of the original powder product and add it to a 250mL crystallizer filled with 100g dichloroethane solvent;

[0065] 2) Warm up to 50°C to dissolve the liquid, and the stirring rate is 200rpm;

[0066] 3) Cool down to 10°C at a uniform speed within 240 minutes;

[0067] 4) Cultivate crystals at a constant temperature for 3 hours at 10°C, filter, and dry to obtain 8.7 g of seed crystals;

[0068] Step 2, crystallization process strengthening:

[0069] 1) Take 329gm of organic mother liquor (mass concentration is about 0.17), add 3.3g of acidic activated carbon powder, and stir for 20min in an oil bath at 50°C at a stirring speed of 200rpm;

[0070] 2) Use a preheated round-bottomed flask and funnel to filter the decolorized mother liquor, quickly place the filtered mother liquor in a crystallizer whose temperature is controlled by an ice machine at 50°C, and program to cool down to 40°C within 20 minutes; ...

Embodiment 3

[0078] Step 1, seed crystal preparation process:

[0079] 1) Take 15g of the original powder product and add it into a 250mL crystallizer filled with 100g dichloroethane solvent;

[0080] 2) Warm up to 53°C to dissolve the liquid, and the stirring speed is 230rpm;

[0081] 3) Cool down to 13°C at a uniform speed within 120 minutes;

[0082] 4) Cultivate crystals at a constant temperature for 4 hours at 13°C, filter, and dry to obtain 9.1 g of seed crystals;

[0083] Step 2, crystallization process strengthening:

[0084] 1) Take 247.4gm of organic mother liquor (mass concentration is about 0.17), add 3.7g of acidic activated carbon powder, and stir for 40min in an oil bath at 53°C at a stirring speed of 230rpm;

[0085] 2) Use a preheated round bottom flask and funnel to filter the decolorization mother liquor, quickly place the filtered mother liquor in a crystallizer whose temperature is controlled by an ice machine at 53°C, and program to cool down to 43°C within 40 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com