Height-adjustable tank container unloading arm

A technology for unloading arms and tanks, which is applied in special distribution devices, packaging, distribution devices, etc. It can solve the problems that tank trains cannot be used and the overall height of the unloading arms cannot be adjusted, and achieve the effect of solving the problem of alignment deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

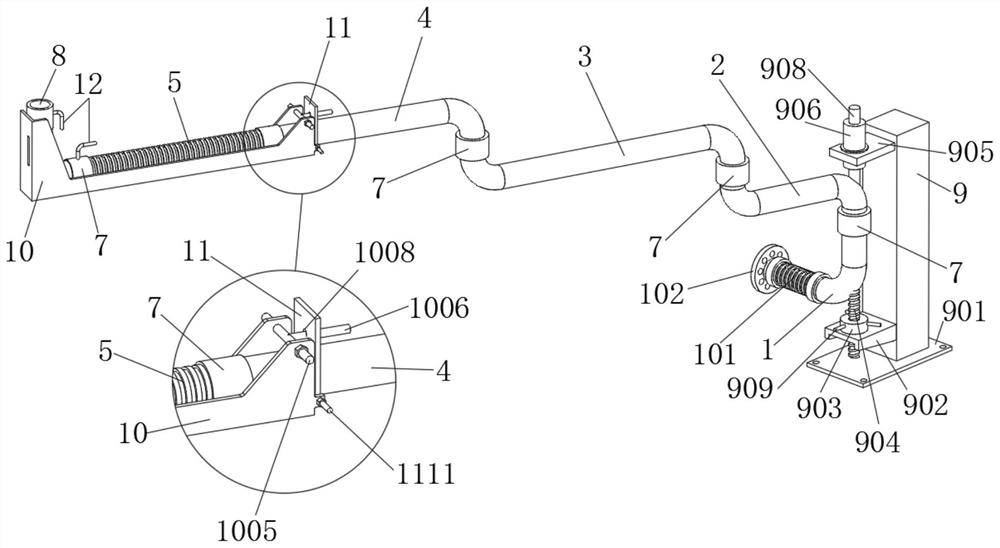

[0056] like Figure 1-2 As shown, a height-adjustable tank container unloading arm includes a combined unloading arm and a support mechanism located on one side of the train track;

[0057] The combined unloading arm includes a lower arm pipe 1, an inner arm pipe 2, a middle arm pipe 3, an outer arm pipe 4, a metal hose 5, and an upper arm pipe 6 connected in sequence by a rotary joint 7; A support assembly for supporting the metal hose 5 with an adjustable pitch angle; the end of the lower arm tube 1 is connected to the hose 101, and the other end of the hose 101 is provided with a connection for connecting with the oil pipeline Flange 102; flexible pipe 101 is set in order to be applicable to the variation of the overall height of combined unloading arm;

[0058] The support mechanism includes a support column 9, and the bottom of the support column 9 is provided with a bottom plate 901 for fixed connection with the ground;

[0059] like Figure 3-5 As shown, the lower su...

Embodiment 2

[0081] On the basis of Embodiment 1, the support assembly includes a grooved support frame 10 and an adjustment plate 11;

[0082] like Figure 1-2 As shown, the lower part of the head end of the grooved support frame 10 is rotationally connected to the bottom end of the outer arm tube 4;

[0083] An adjustment column 1005 extending along the horizontal direction is arranged on the top of the head end of the trough-shaped support frame 10; the central axis of the adjustment column 1005 is perpendicular to the central axis of the outer arm tube 4;

[0084] The middle part of the adjustment column 1005 is vertically fixed with an adjustment stud 1006 extending toward the head end of the outer arm tube 4; the end of the adjustment stud 1006 is provided with an adjustment nut 1007;

[0085] The adjustment plate 11 is fixed vertically on the upper outer wall surface of the outer arm pipe 4, and the adjustment plate 11 is provided with a waist-shaped hole 1008 for the adjustment sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com