Water-free type plastic film master batch dust washing device

A plastic film and cleaning device technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of increased energy consumption, waste, cumbersome collection work, etc., to avoid collisions of powder and fine particles, The effect of reducing the collision strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

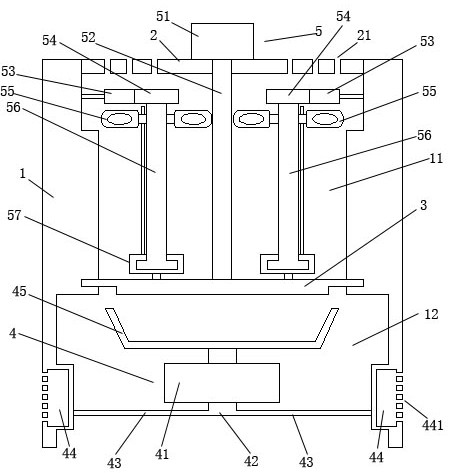

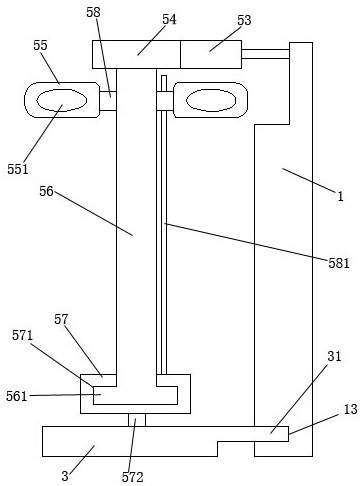

[0014] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] like figure 1 and 2 As shown, an anhydrous plastic film masterbatch dust cleaning device includes a tank body 1, a friction stirring mechanism 5, a blower mechanism 4, a connecting cover plate 2, and a rotating perforated plate 3; the upper end of the tank body 1 is equipped with a connecting cover plate 2; the two sides of the connecting cover plate 2 are evenly provided with vent holes 21; the bottom of the tank body 1 is rotated and clamped to install a rotating perforated plate 3; the rotating perforated plate 3 separates the inside of the tank body 1 It is the friction stir chamber 11 above and the air blowing chamber 12 below; the friction stir mechanism 5 is installed in the friction stir chamber 11; the friction stir mechanism 5 includes a drive motor 51, a rotating shaft 52, a positioning gear ring Body 53, two positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com