Raw material cooking device for cosmetic production

A technology for cooking devices and cosmetics, applied in chemical instruments and methods, solid solvent extraction, solvent extraction, etc., can solve the problems of general cooking uniformity of materials, easy floating of materials, stacking, and single structural heating method, etc., to improve the cooking effect. , Guarantee the effect of cooking and increase the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

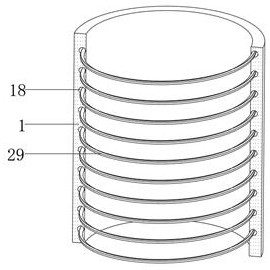

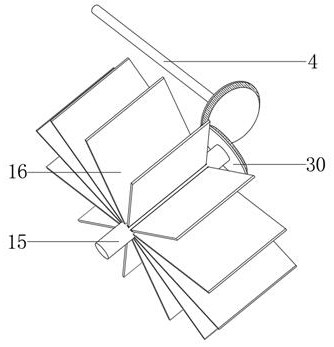

[0030] refer to Figure 1-4 , a raw material cooking device for cosmetics production, comprising a cooking drum 1, a base plate 24 is welded to the bottom outer wall of the cooking drum 1, and the bottom plate 24 and the cooking drum 1 form a heating chamber 19, and the bottom outer wall of the cooking drum 1 is provided with equidistantly distributed The arc-shaped groove 22, and the inner wall of the arc-shaped groove 22 is welded with protruding pieces 23 distributed in a fan shape, the top inner wall of the heating chamber 19 is welded with an installation cylinder 26 with openings at both ends, and the inner walls at both ends of the installation cylinder 26 A heating wire 25 is fixedly installed, and the inside of the cooking cylinder 1 is provided with a spiral hot air passage 18, and one side of the inner wall of the hot air passage 18 is welded with a heat exchange fin 29, and the cross section of the heat exchange fin 29 is claw-shaped. The top of the cooking cylinde...

Embodiment 2

[0041] refer to Figure 5 , a raw material cooking device for cosmetics production. Compared with Embodiment 1, this embodiment further includes that the inner wall of the installation cylinder 26 is fixedly installed with oblique spiral pieces 31 distributed equidistantly.

[0042] When the present invention is in use: Utilize oblique helical pieces 31 equidistantly distributed on the inner wall of the installation cylinder 26, when the air pump 27 acts, it plays a role of guiding and buffering the air, thereby ensuring that the heating wire 25 fully absorbs the air. Heat treatment to ensure the heating efficiency of the cooking cylinder 1 through the hot air channel 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com