Device and method for detecting air permeability of mildew-proof roll paper for glass stacking

A detection device and air permeability technology, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as abnormal chip loss, and achieve the effect of ensuring tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

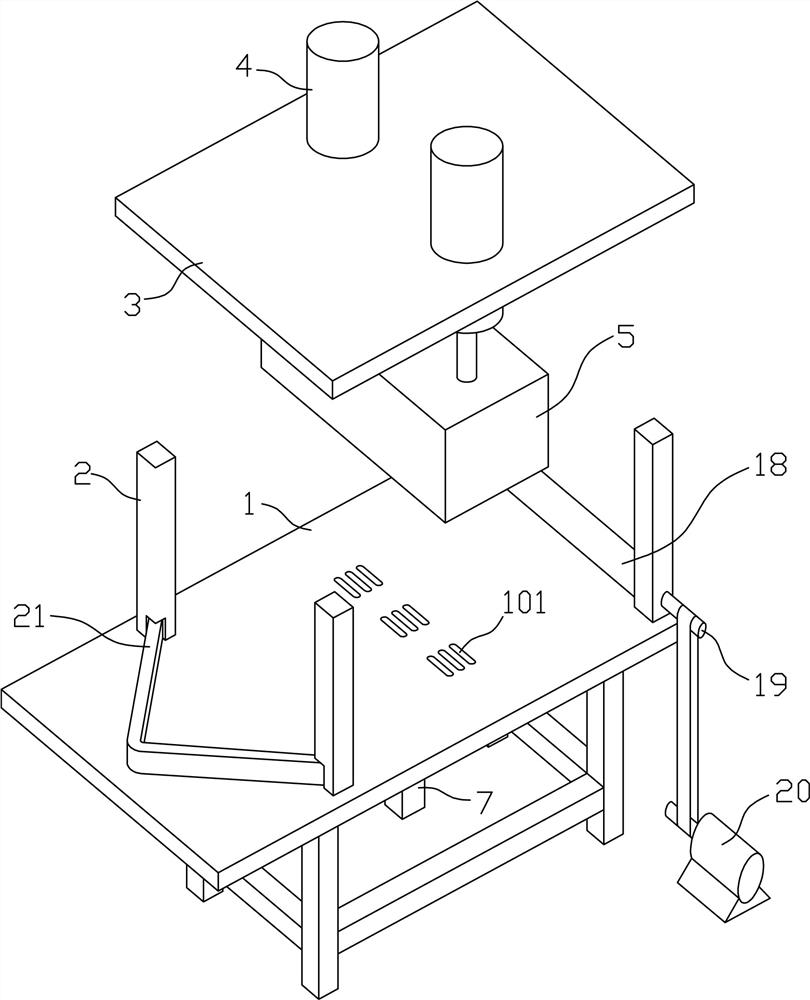

Image

Examples

Embodiment 2

[0052] A detection method for an air permeability detection device used for mold-proof rolling paper for glass stacking, comprising the following steps:

[0053] 1) Feed the anti-mildew roll paper from the paper feed end of the table panel 1, so that the anti-mold roll paper passes under the cardboard 21;

[0054] 2) Manually pull the end of the anti-mildew roll paper to pass through the paper feed roller 18;

[0055] 3) Open the second shut-off valve 13, and ensure the first shut-off valve 12, and carry out negative pressure on the negative pressure tank 9 through the negative pressure pump 11;

[0056] 4) When the pressure value on the digital display pressure gauge 14 reaches the preset negative pressure value (for example -1bar), close the second stop valve 13;

[0057] 5) Open the first cut-off valve 12 through the controller 15, and start the motor 20 at the same time, and perform continuous air permeability detection on the anti-mildew roll paper.

[0058] In the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com