Wall column type upward horizontal layered filling mining method

A backfill mining method and pilaster technology, which is applied in the fields of backfill, surface mining, mining equipment, etc., can solve the problems of large stope support workload, high stope filling cost, poor stope mining safety, etc. The effect of stope support workload, speeding up stope operation cycle and improving stope production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

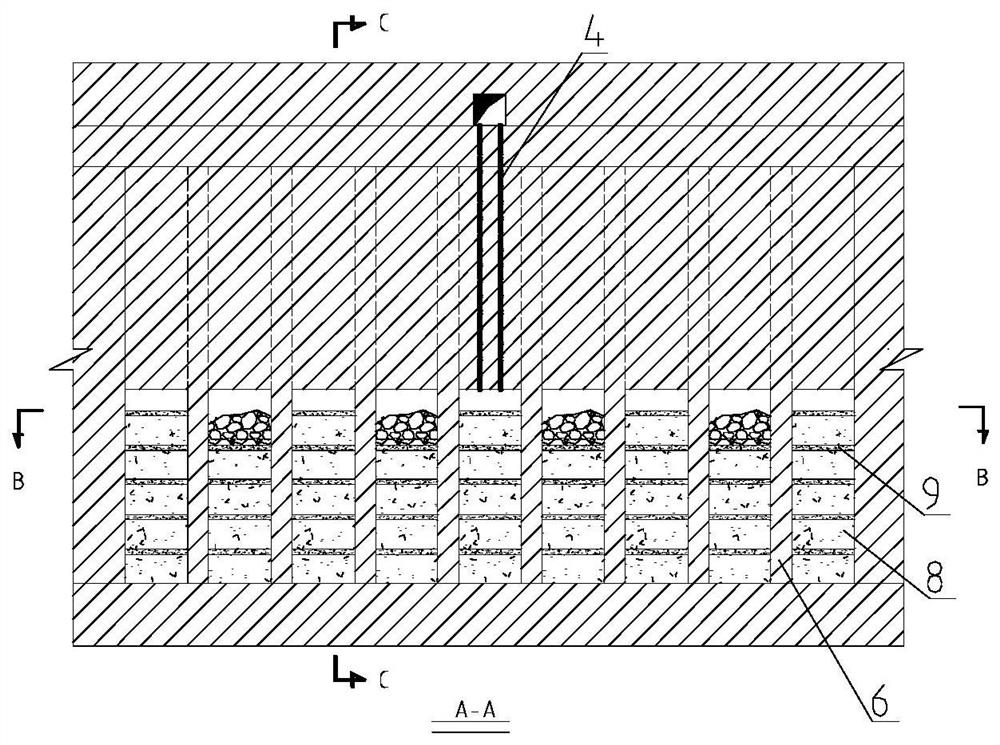

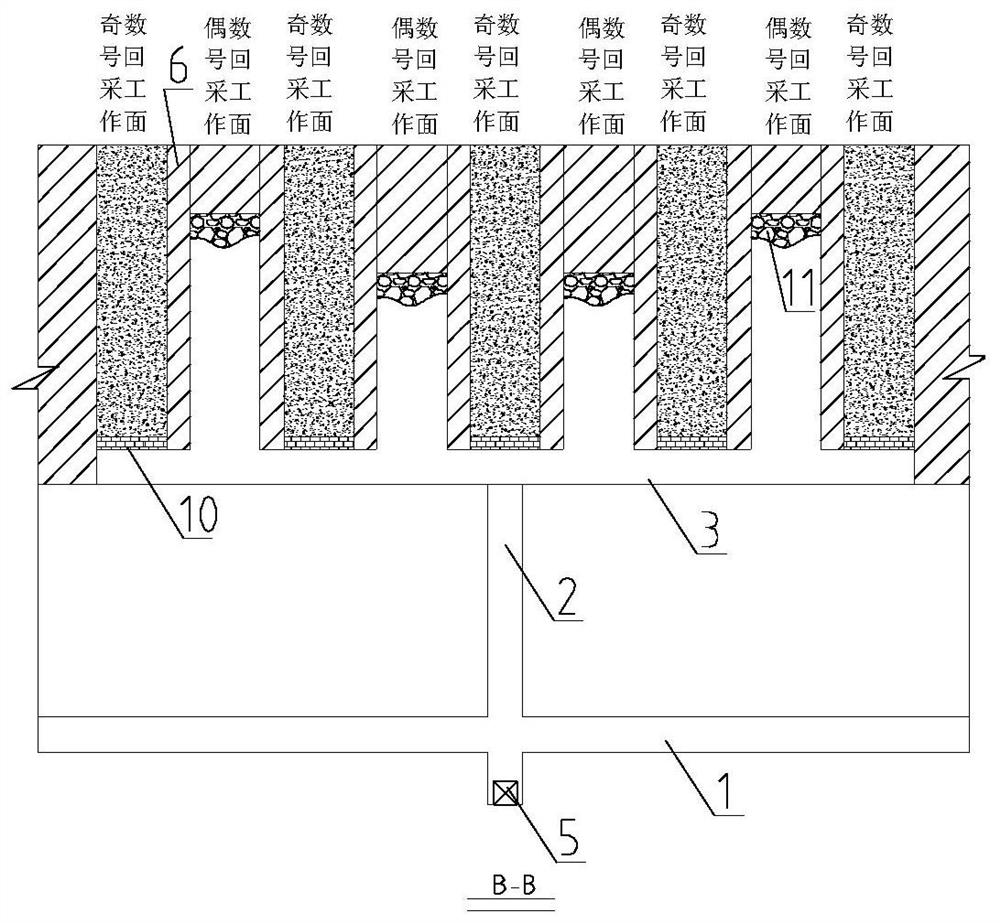

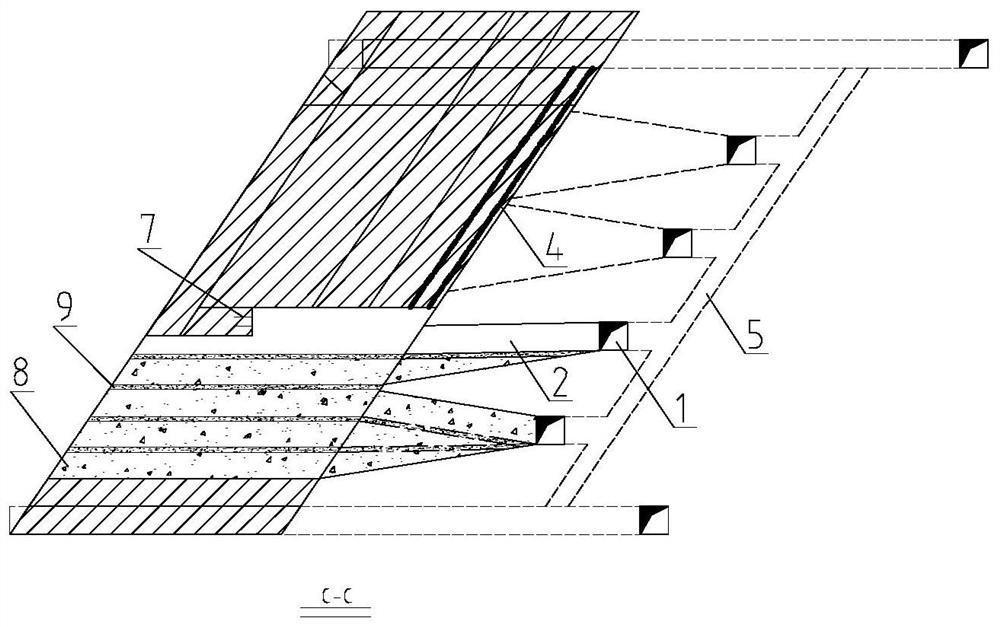

[0026] The technical solutions of the various embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them; based on the embodiments of the present invention, All other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0027] The ore-hosting rocks of the No. 1 orebody of a lead-zinc mine are mainly glutenite and pebble-bearing sandstone, followed by sandstone. The orebodies in the north and south flanks are layered, with partial branching and composite phenomena, and the occurrence of the orebody is basically consistent with the occurrence of the stratum. The southern wing ore body is controlled by a total of 55 exploration lines from S12 to S66, with a length of about 2250m and extending along the dip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com