Energy-saving and convenient-to-adjust assembly type dry-hanging wall surface

A prefabricated, dry-hanging technology, applied in covering/lining, building, building structure, etc., can solve problems such as difficult adjustment, uneven plane, time-consuming and labor-intensive, and achieve the effect of fast and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

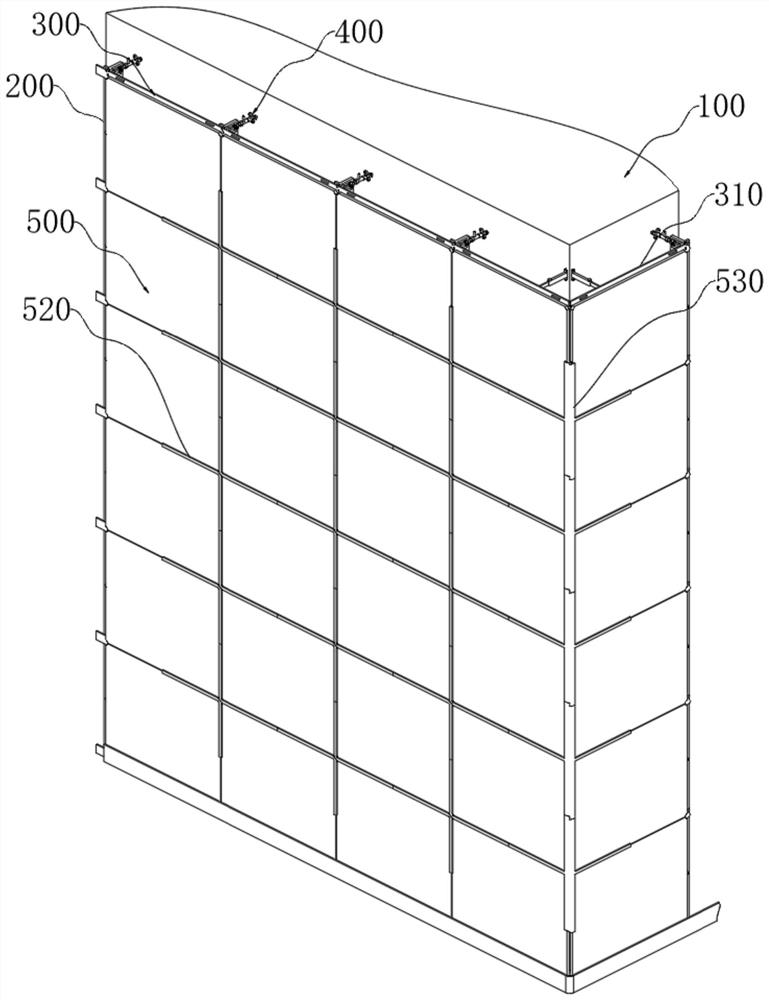

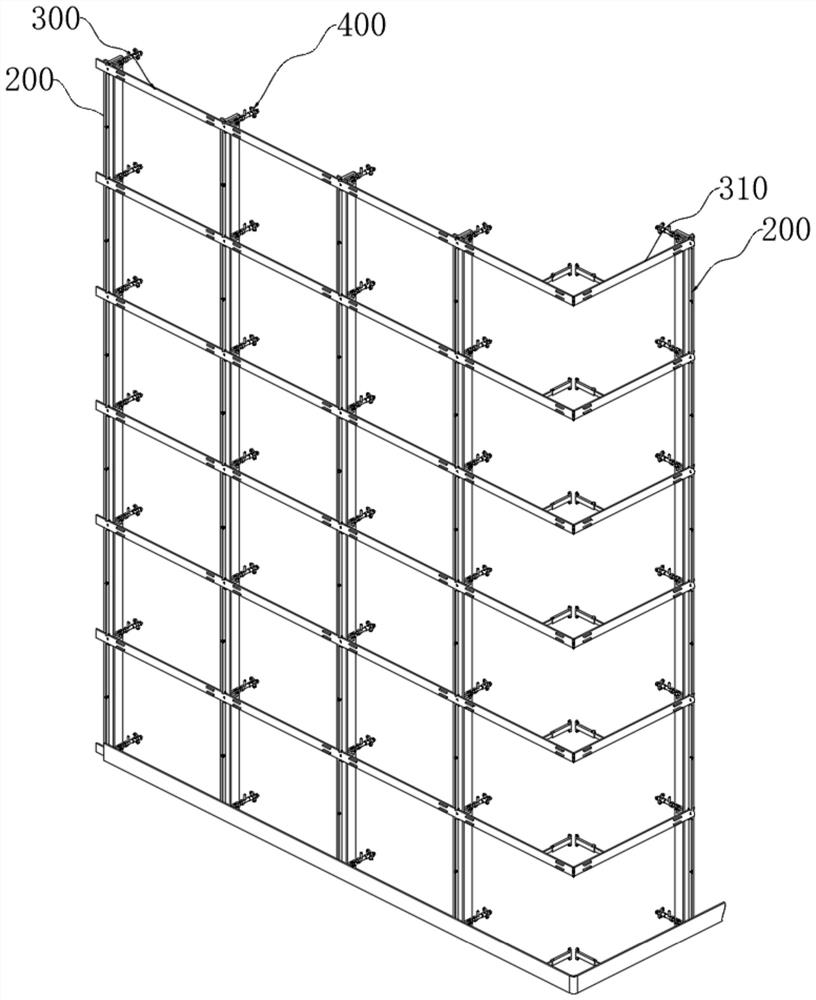

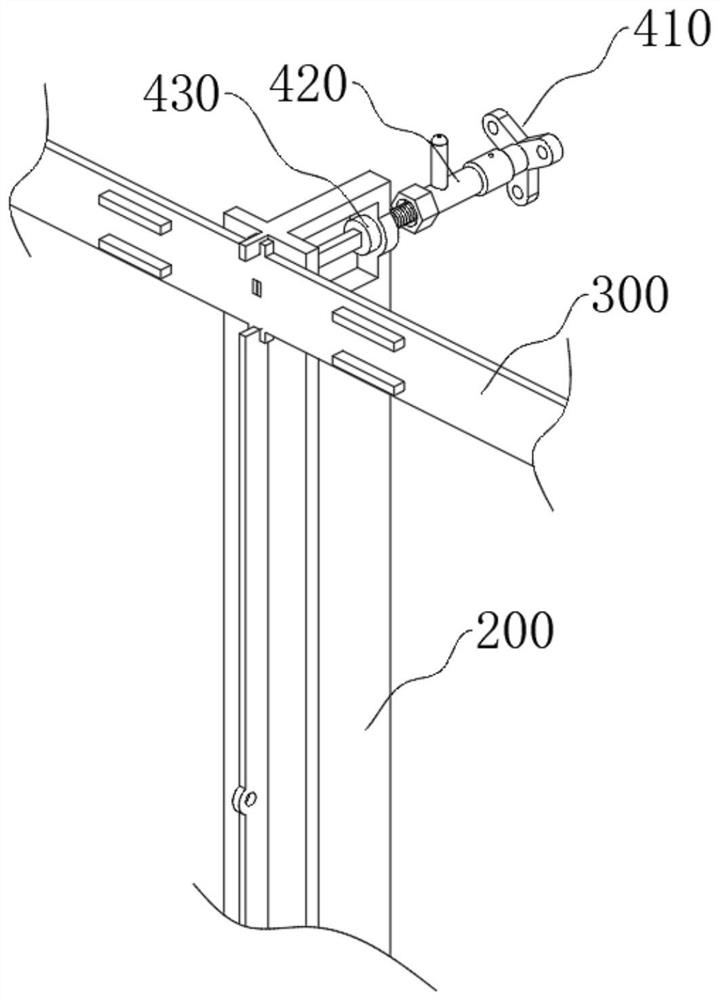

[0057] see Figure 1 to Figure 19 As shown, the present invention provides an energy-saving and easy-to-adjust assembled dry-hanging wall surface, which includes a wall body 100 of a house. The front side of the body of wall 100 is provided with a number of vertical hanging walls at equal intervals along its horizontal direction. Rod 200, the front side of vertical hanging rod 200 and equidistant along its height direction are provided with several horizontal hanging rods 300 placed horizontally, and several vertical hanging rods 200 and some horizontal hanging rods 300 are assembled into several equal-area openings and pass through A panel 500 is installed at the mouth. The rear end of each vertical hanging rod 200 is provided with a plurality of adjustment components 400 that can adjust the flatness of the intersection of the vertical hanging rod 200 and the horizontal hanging rod 300 . The adjustment assembly 400 includes a three-spoke fixed member 410 fixed on the wall 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com