Underground continuous wall provided with water stop component for blocking seepage path

An underground diaphragm wall and water-stop technology, which is applied in excavation, construction, and infrastructure engineering, can solve the problems of concrete pouring and tamping, such as inconsistency and fracture, and achieve the effect of improving construction quality and improving the safety of foundation pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

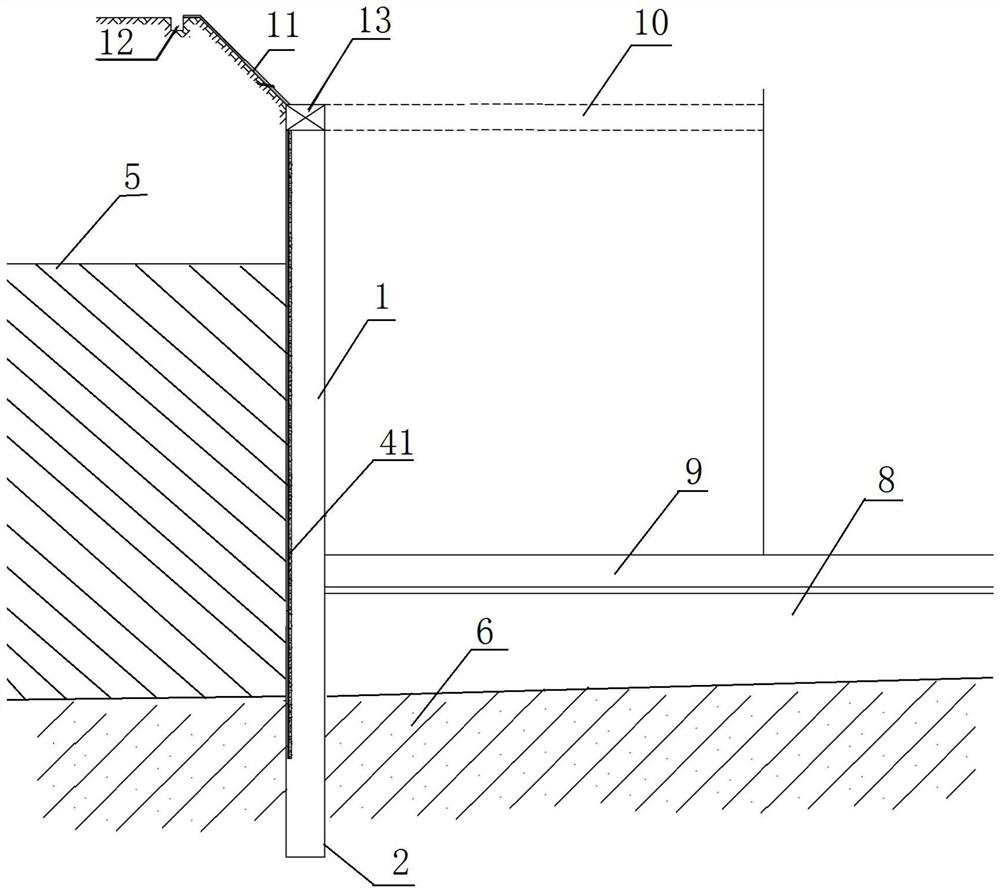

[0029] An underground continuous wall provided with a water-stopping component to block the seepage path, comprising an underground continuous wall 1, the underground continuous wall 1 is equipped with a water-stopping component, and both the underground continuous wall 1 and the water-stopping component are located at the bottom of the underground continuous wall 1 Inside the wall groove 2 ; the underground continuous wall 1 is a cast-in-situ concrete structure, and the underground continuous wall 1 is embedded with a steel mesh 3 , and the water-stop component is fixedly connected with the steel mesh 3 .

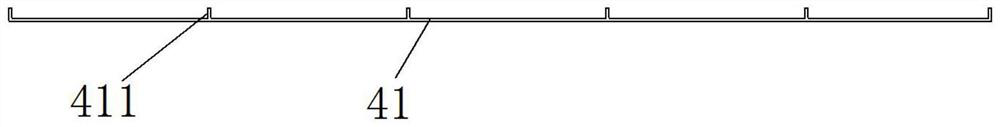

[0030] In order to further optimize the above-mentioned technical scheme, the waterproof component is an anti-seepage and water-proof composite plate 41, and the anti-seepage and water-proof composite panel 41 is located between the inner wall of the wall groove 2 and the earth-facing surface of the underground continuous wall 1, and the anti-seepage and water-proof composit...

Embodiment 2

[0040] An underground continuous wall provided with a water-stopping component to block the seepage path, comprising an underground continuous wall 1, the underground continuous wall 1 is equipped with a water-stopping component, and both the underground continuous wall 1 and the water-stopping component are located at the bottom of the underground continuous wall 1 Inside the wall groove 2 ; the underground continuous wall 1 is a cast-in-situ concrete structure, and the underground continuous wall 1 is embedded with a steel mesh 3 , and the water-stop component is fixedly connected with the steel mesh 3 .

[0041] In order to further optimize the above technical solution, the water-stop component is a bent type water-stop composite plate 42, which is located in the underground continuous wall 1; the bent-type water-stop composite plate 42 adopts multiple built-in water-stop The plates are spliced along the length direction of the underground continuous wall 1 to form a plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com