An ultra-stable mineralizer and its application in repairing heavy metal polluted soil

A technology of polluted soil and mineralizer, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve the problems of pollutant desorption pollution, cumbersome preparation process, high dosage, etc., and achieve continuous synthesis and wide range of raw materials. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

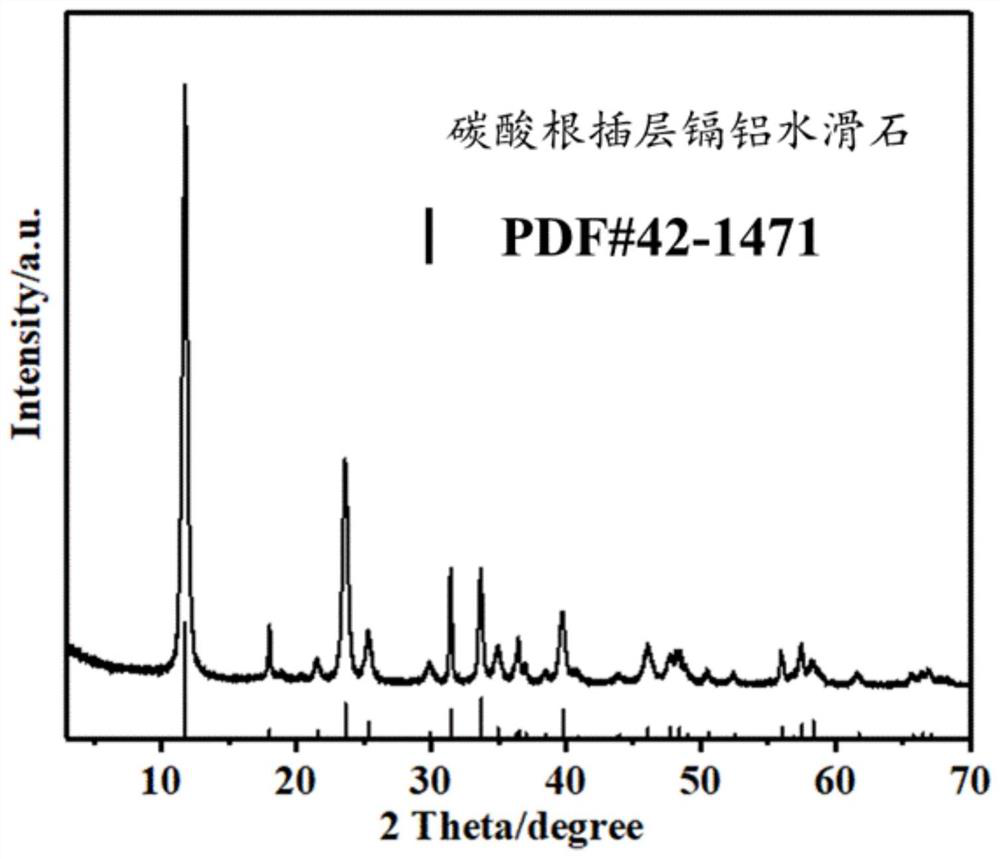

[0037] Weigh 23.6g Ca(NO 3 ) 2 ·4H 2 O was dissolved in 500 ml of deionized solution A to obtain solution A, and 4.1 g of NaAlO was weighed 2 Dissolve in 500ml of deionized water to obtain solution B, quickly add solutions A and B to the micro-liquid membrane reactor with a rotating speed of 3000r / min at the same time, collect the slurry at the discharge port, and dry it at 40°C for 12 hours after centrifugal washing with deionized water. Calcium-based ultra-stable mineralizer was obtained. figure 1 It is the XRD pattern of the prepared material. It can be seen from the figure that the prepared calcium-aluminum composite material calcium-based ultra-stable mineralizer exhibits the structural characteristics of a layered material, and there is no calcium carbonate, calcium hydroxide, aluminum hydroxide and other substances. Diffraction peak, the composite material prepared on the surface is a single phase structure.

Embodiment 2

[0039] Weigh 29.4gCaCl 2 ·2H 2 O was dissolved in 500 ml of deionized solution A to obtain solution A, and 8.2 g of NaAlO were weighed 2 Dissolve in 500ml of deionized water to obtain solution B, quickly add solutions A and B to the micro-liquid membrane reactor with a rotating speed of 3000r / min at the same time, collect the slurry at the discharge port, and dry it at 40°C for 12 hours after centrifugal washing with deionized water. Can. The transmission electron microscope image of the as-prepared material is shown in Figure 9 , showing a random nanoscale two-dimensional flake structure.

Embodiment 3

[0041] Weigh 37.0gCa(OH) 2 Dissolve in 500ml of deionized solution to obtain suspension A, weigh 20.1g of NaAlO 2 Dissolve in 500ml of deionized water to obtain solution B, quickly add solutions A and B to the micro-liquid membrane reactor with a rotating speed of 3000r / min at the same time, collect the slurry at the discharge port, crystallize at 120 ℃ for 8 hours and then deionize Wash by centrifugation in water and dry at 40°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com