Screw roller screen for separating concrete to recycle gravels

A technology for separation and recovery of concrete, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of increasing equipment cost, increasing equipment footprint, and occupying a certain area, so as to achieve small footprint, increase material accumulation height, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below through specific embodiments.

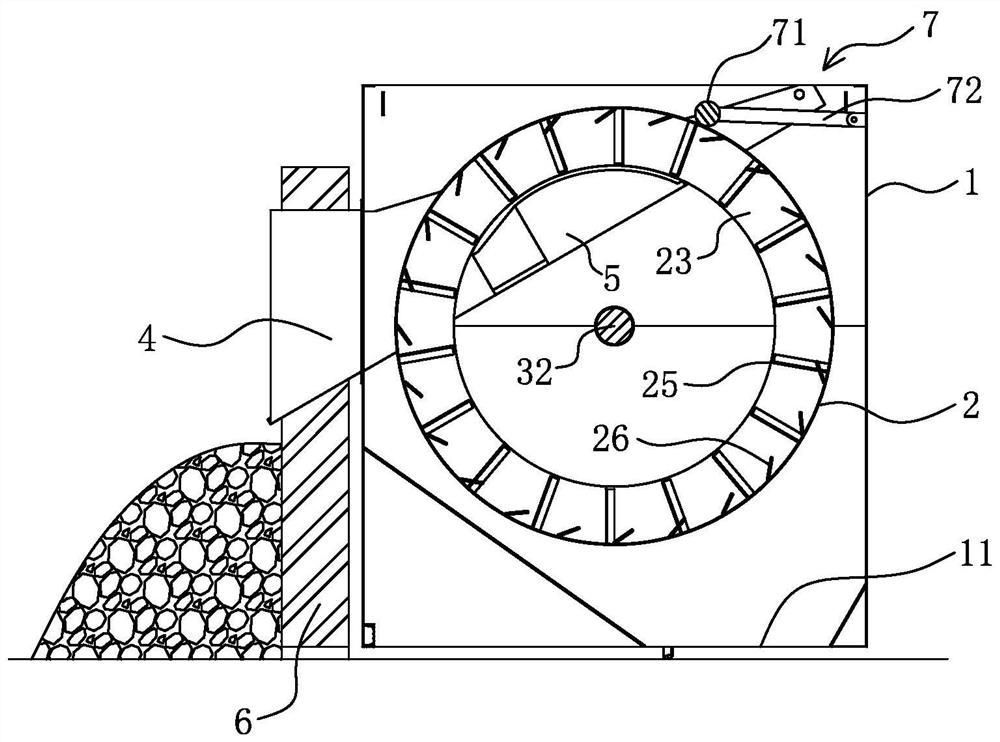

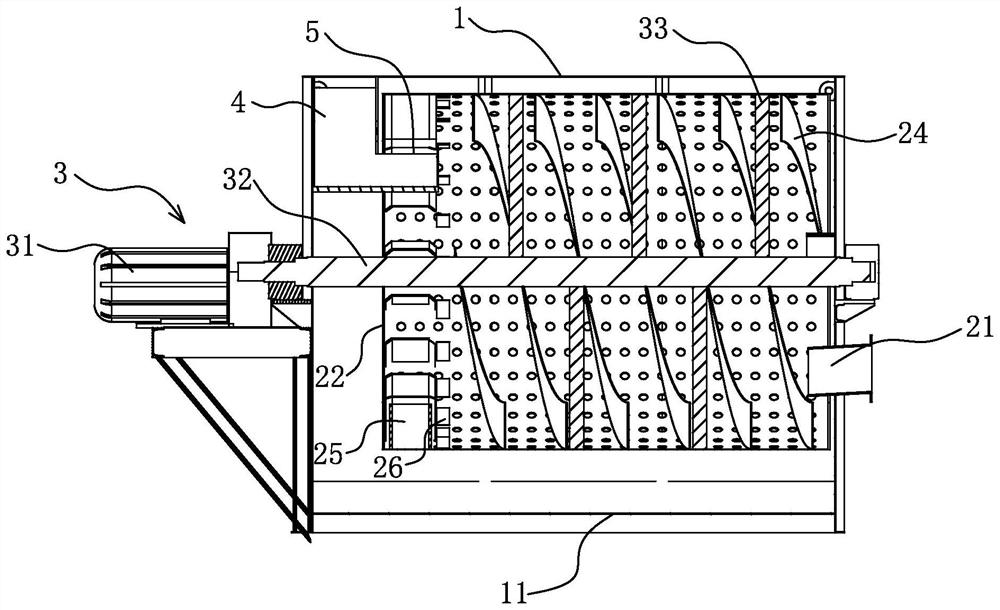

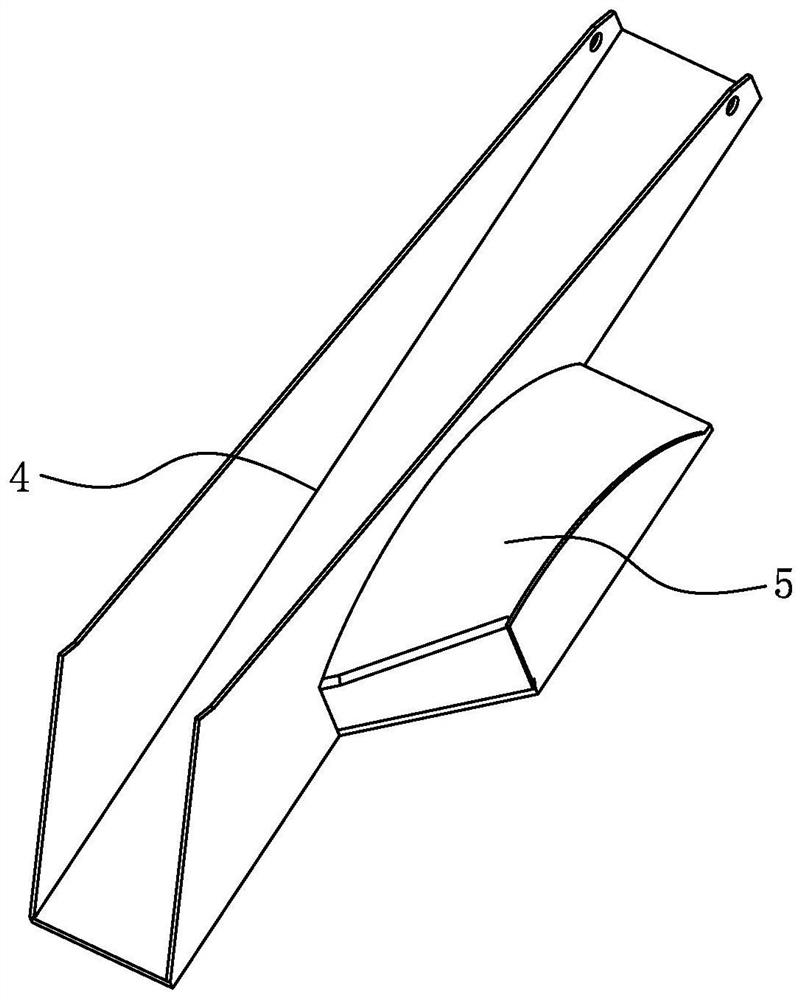

[0021] refer to Figure 1 to Figure 5 As shown, a spiral roller screen for separating and recovering sand from concrete includes a shell 1, a drum 2, a driving mechanism 3, a discharge chute 4, a receiving trough 5, a partition wall 6, and a beating device 7.

[0022] The shell 1 is fixed, and the bottom of the shell 1 is provided with a mortar water discharge port 11. The drum 2 is arranged in the shell 1. One end of the drum 2 is provided with a material inlet 21, and the other end is provided with a discharge port 22. The surface of the drum 2 is The mesh structure is densely covered with openings, and the driving mechanism 3 drives the drum 2 to rotate.

[0023] The drum 2 includes an annular sealing plate 23. There are two annular sealing plates 23, which are located at both ends of the drum 2 respectively. There are spiral blades 24, material lifting blades 25, and material pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com