A kind of bearing defect detection equipment

A defect detection and bearing technology, applied in the direction of mechanical bearing testing, measuring devices, testing of mechanical parts, etc., to achieve the effect of improving detection accuracy and detection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

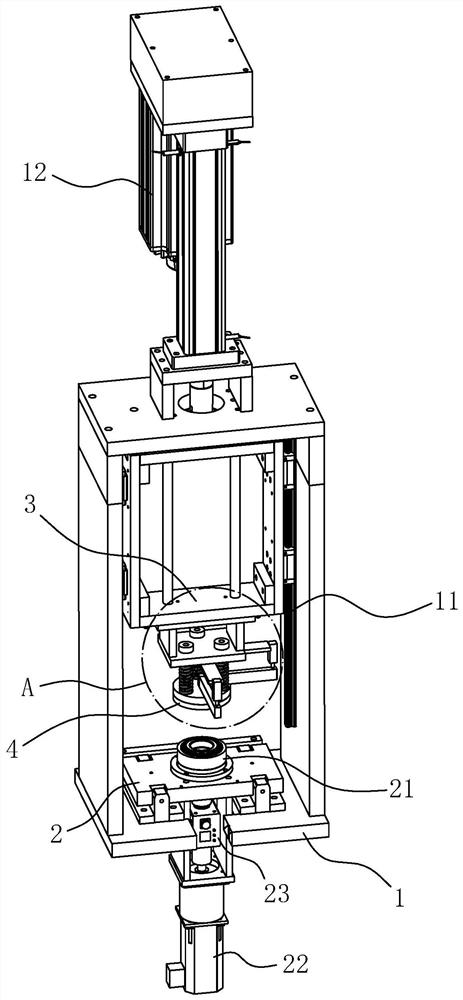

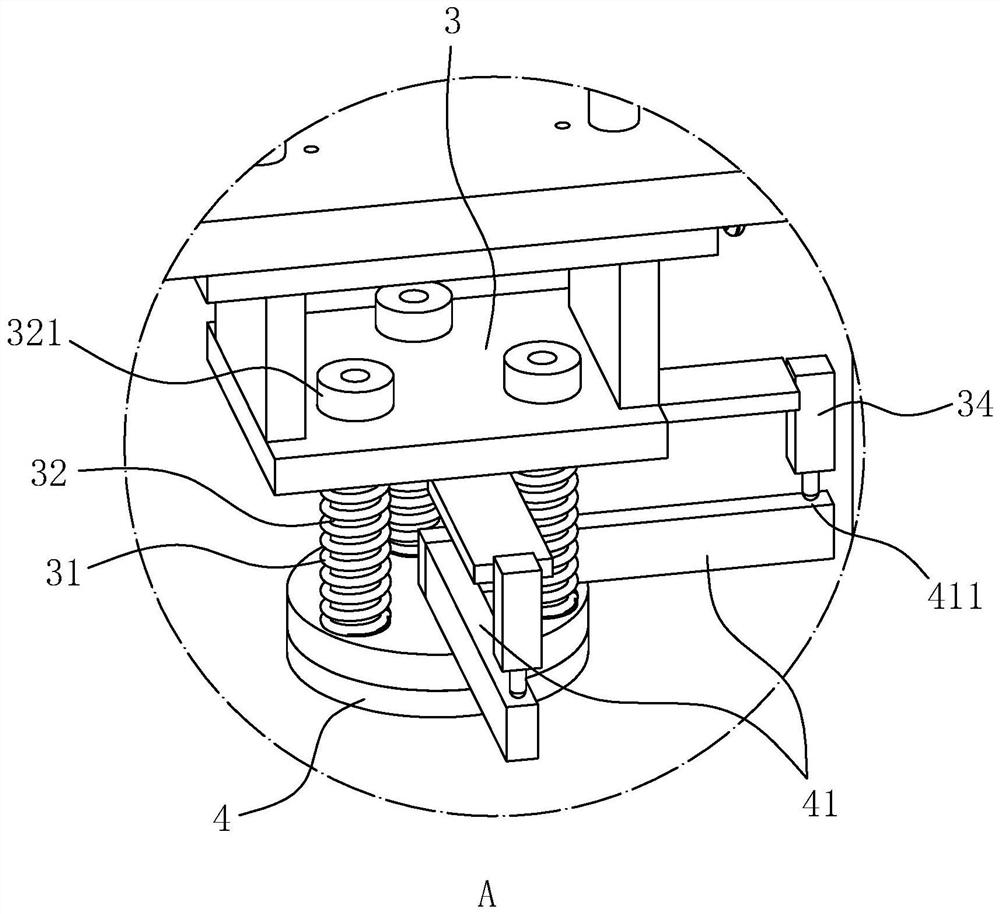

[0036] The embodiment of the present application discloses a bearing defect detection device. refer to figure 1 , the bearing defect detection equipment includes a frame 1, the frame 1 is provided with a mounting frame 2, the mounting frame 2 is provided with a mounting seat 21, a drive motor 22 that drives the mounting seat 21 to rotate, and the mounting seat 21 is used to place the to-be-detected bearing. The rack 1 is also slidably provided with a top seat 3, the top seat 3 is located directly above the mounting frame 2, and the bottom surface of the top seat 3 is provided with a pressure head 4, and the pressure head 4 and the mounting seat 21 are respectively used for the two bearings of the bearing to be detected. A ring is fixed.

[0037] The sliding direction of the top seat 3 is in the vertical direction. The sliding rail 11 is provided between the top seat 3 and the frame 1 to establish a sliding connection. The top seat 3 is driven to slide by a driving source 12,...

Embodiment 2

[0049] The embodiment of the present application also discloses a bearing defect detection device. The difference between the second embodiment and the first embodiment is that:

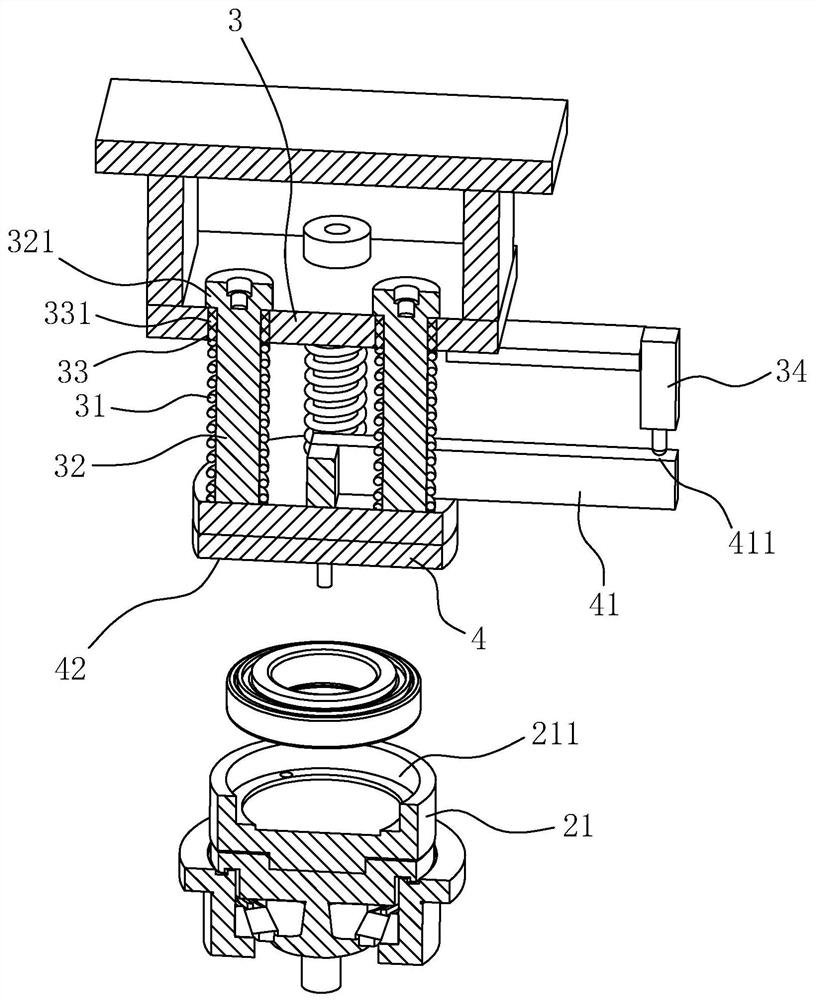

[0050] refer to Figure 4 and Figure 5 , a pad 13 is fixed on the rack 1, and the pad 13 supports the weight of the mounting frame 2 through the top surface. If the top surface of the cushion block 13 is inclined to the horizontal plane, the mounting base 21 is inclined in accordance with the inclination direction of the top surface of the cushion block 13 ; In this state, the press head 4 can still press the bearing by self-adaptive rotation.

[0051] When the detection device of this embodiment performs detection, the rotation axis of the bearing deviates from the vertical direction, and the force of the indenter 4 pressing on the bearing is still in the vertical direction, then the indenter 4 will exert a radial force on the bearing, so that the bearing Resistance and defect detection are carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com