Same-hole multi-slurry injection machine tool and same-hole multi-slurry injection plugging method

A technology of grout and tools, which is applied in the fields of multiple grout injection machines in the same hole and multiple grout injection plugging in the same hole. The process is convenient, the effect is good, and the effect of saving the cost of production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

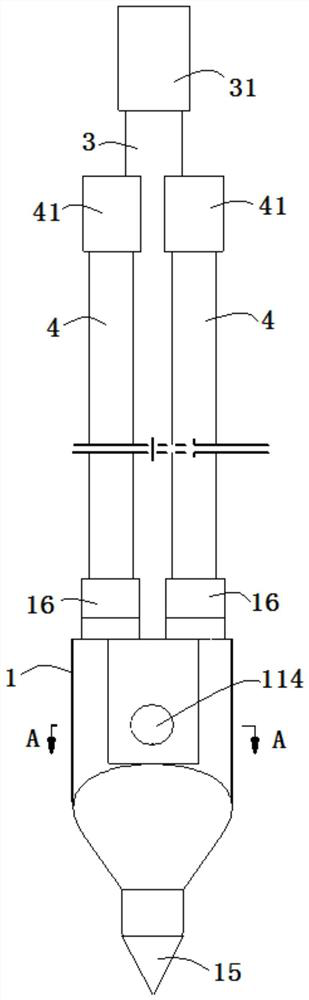

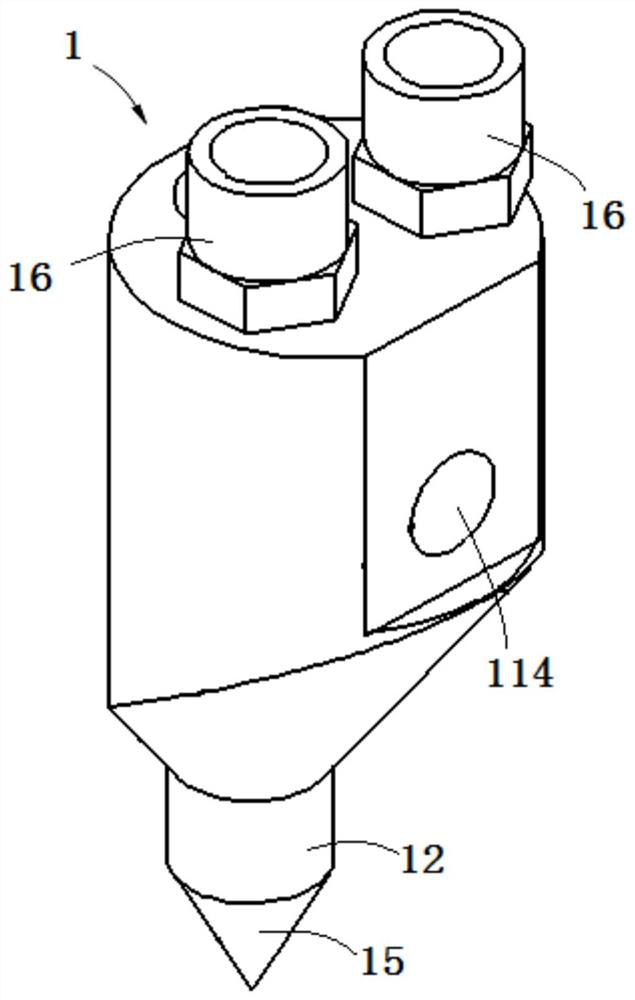

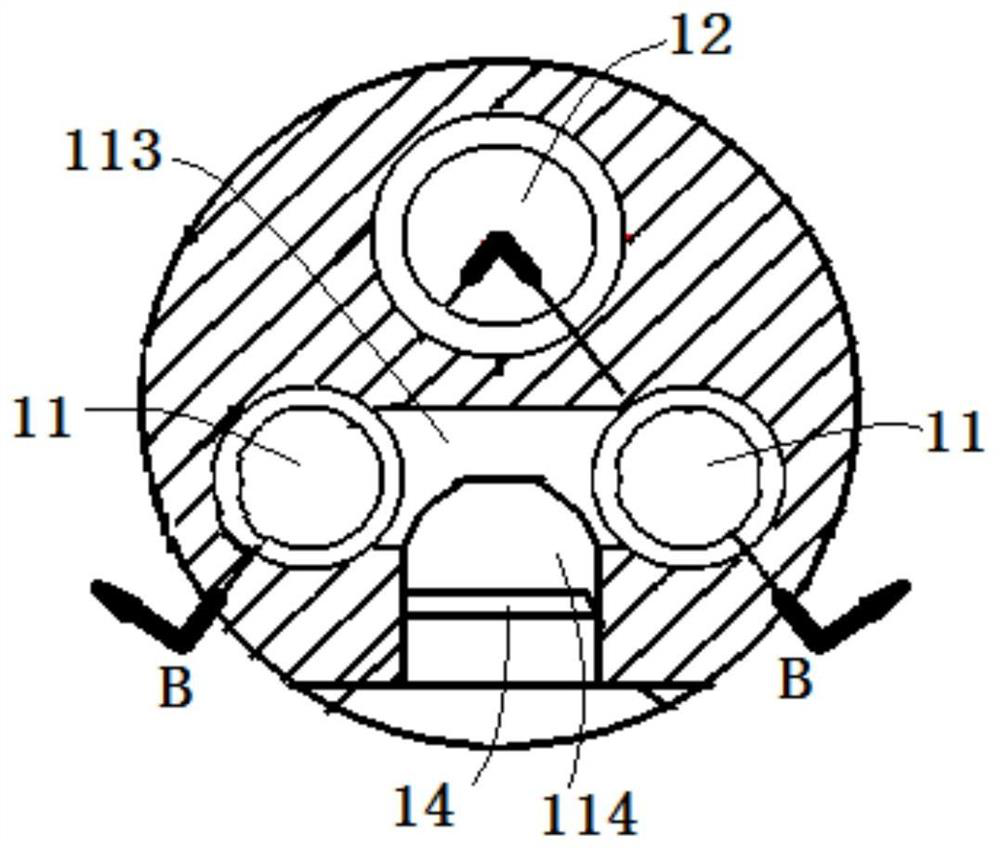

[0035] see figure 1 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a variety of grout injection equipment in the same hole, including: a grouting head body 1, a one-way valve core 13, a first temporary plug 14, a second temporary plug 15, a hard grouting pipe 3, The grouting hose 4, the hose outer joint 41, the hard pipe outer joint 31, the grouting head body 1 includes two first grouting cylinder parts 11 arranged side by side and the two first grouting cylinder parts 11 arranged side by side. The second grouting cylinder part 12 on one side, the one-way valve core 13 includes a hollow cylindrical body 131 and an elastic sealing sleeve 132 sleeved outside the cylindrical body 131, and the middle outer wall of the cylindrical body 131 is formed Pulp outlet hole 133 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com