Multifunctional universal water spraying device for cloth dyeing machine

A water-spraying device and multi-functional technology, applied in the field of dyeing machines, can solve the problem that the nozzle holder and the nozzle are not common, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

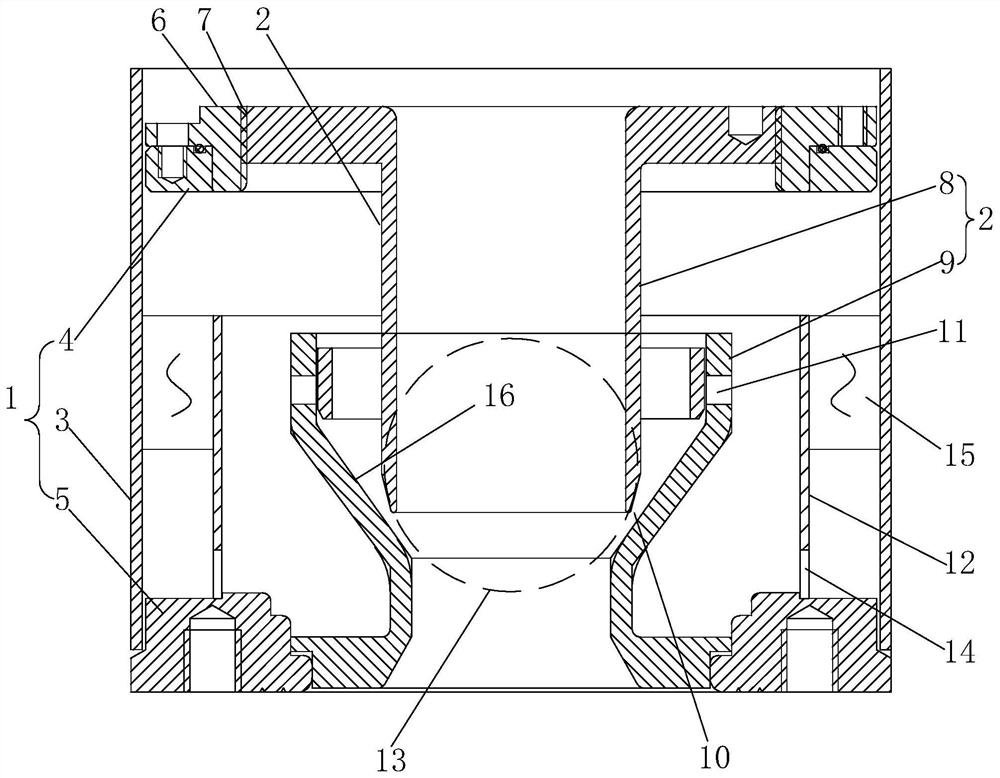

Embodiment 1

[0030] refer to figure 1 , including a nozzle seat 1 and a nozzle 2, the nozzle seat 1 is composed of a casing 3, a first annular block 4, and a second annular block 5, the casing 3 is in the shape of a cylinder with two ends open, and the first annular block 4 is fixed on the bottom of the casing 3 One end, the second annular block 5 is fixed on the other end of the shell 3, the nozzle 2 is installed in the shell 3, between the first annular block 4 and the second annular block 5, the first annular block 4, the second annular block 5, the nozzle 2 are all coaxial with the shell 3.

[0031] Such as figure 1 As shown, the side wall of the casing 3 has a circular water inlet 13, and the water inlet 13 is connected to the water pipe. An inner sleeve 12 is also fixed inside the casing 3 , the inner sleeve 12 surrounds the nozzle 2 and is coaxial with the nozzle 2 , and the bottom of the inner sleeve 12 is fixed on the second ring block 5 . The side wall of the inner sleeve 12 h...

Embodiment 2

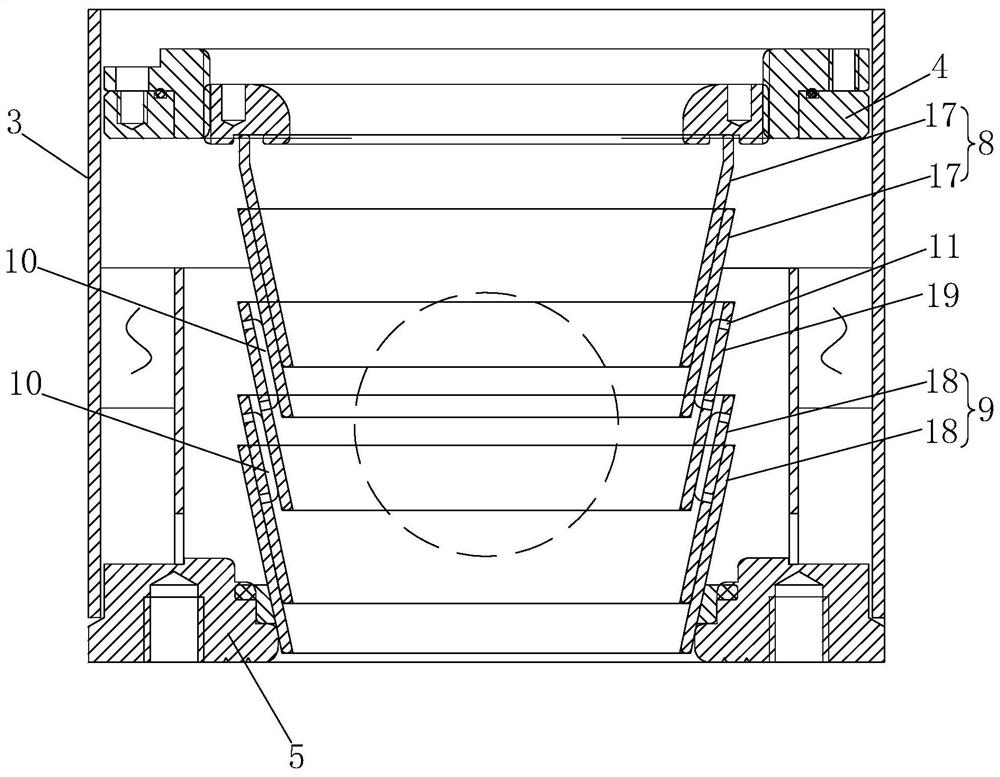

[0037] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that the shapes of the inner insert 8 and the outer sleeve 9 are different, and a third frustum-shaped sleeve 19 is coaxially sleeved between the inner insert 8 and the outer sleeve 9 .

[0038] Such as figure 2 As shown, the inner insert 8 of this embodiment is composed of a first frustoconical sleeve 17 that is socketed in two layers, and the outer sleeve 9 is composed of a second frustoconical sleeve 18 that is socketed in two layers. The first frustoconical sleeve 17 And the tip of the second frustum-shaped sleeve 18 all points to the second annular block 5 .

[0039] Such as figure 2As shown, the third truncated cone sleeve 19 is also provided with threaded holes 11 for installing screws, and the screws on the outer sleeve 9 are used to withstand the outer wall of the third truncated cone sleeve 19, and the screws on the third truncated cone sleeve 19 Screws are used to butt agains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com