Automatic destacking and unpacking line for bagged materials

An automatic unloading and wrapping technology, which is applied in the directions of packaging, object stacking, object destacking, etc., can solve the problems of low production efficiency, low degree of automation, inconvenience, etc., and achieve continuous action, compact overall structure, simple and reasonable , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

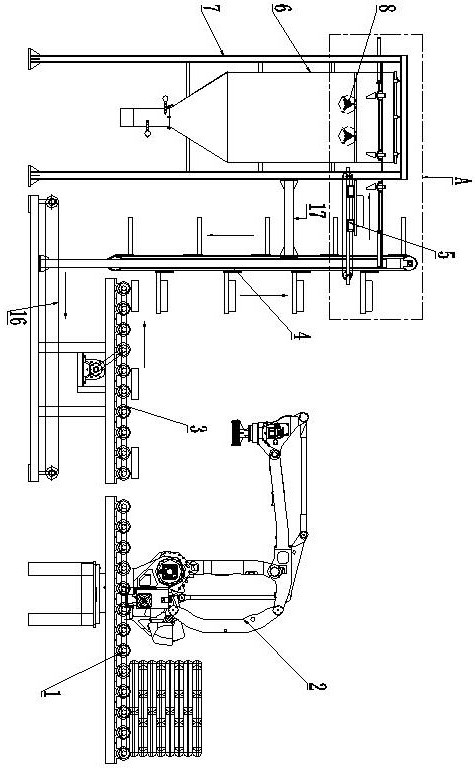

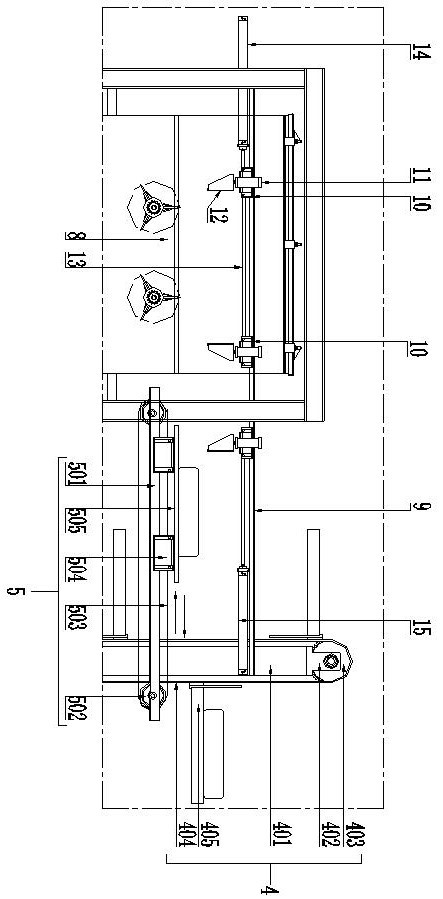

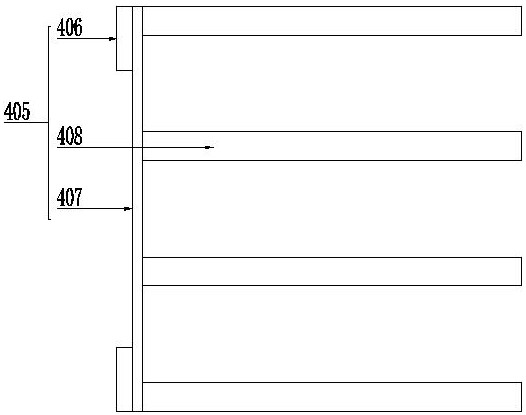

[0029] like Figure 1-Figure 6 Commonly shown, the present invention provides an automatic depalletizing and unpacking line for bag loading, including a buffer conveyor line 1, a feed conveyor line 3, a vertical transfer device 4, a reciprocating transfer device 5 and a bag breaking device 8; The conveying end of the conveying line 1 is connected with the conveying initial end of the feeding conveying line 3, and a depalletizing robot 2 is installed on one side of the conveying end of the buffer conveying line 1, and a vertical conveying device 4 is installed at the conveying end of the feeding conveying line 3 One side of the vertical conveying device 4 is used for vertically upward lifting of bagged materials, and the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com