Rear-mounted rear-drive system of electric automobile

An electric vehicle and rear suspension technology, applied in the direction of electric power devices, power devices, control devices, etc., can solve the problems of high cost and difficult assembly, and achieve the effect of low cost, small assembly difficulty and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

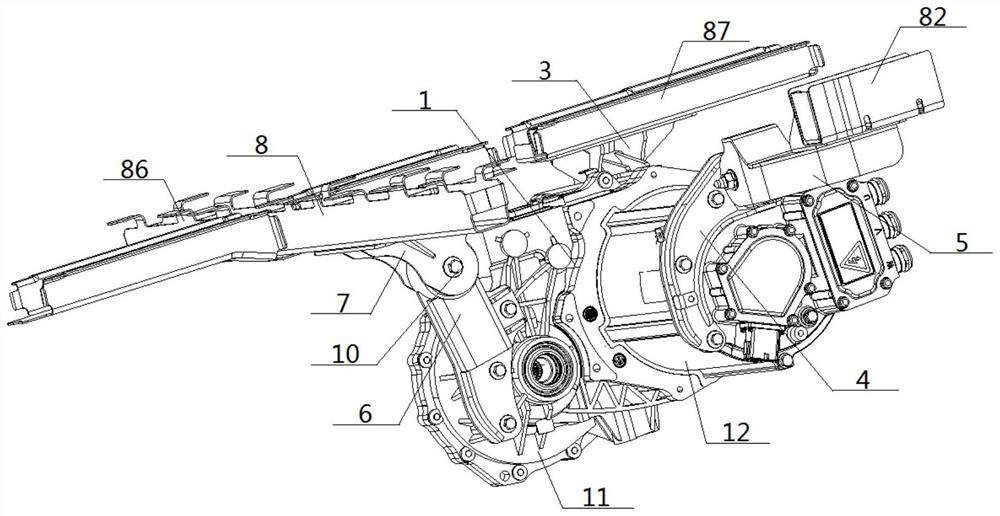

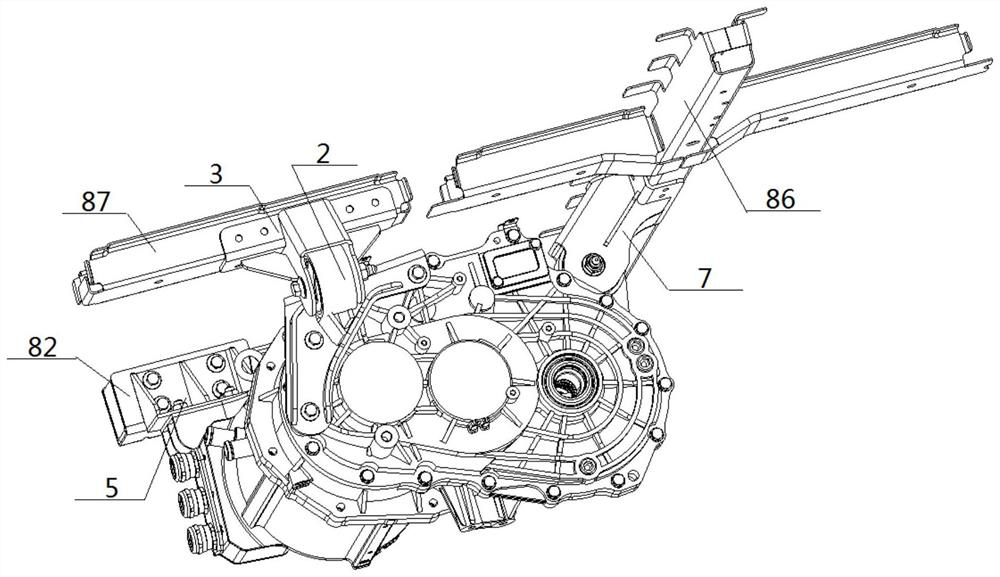

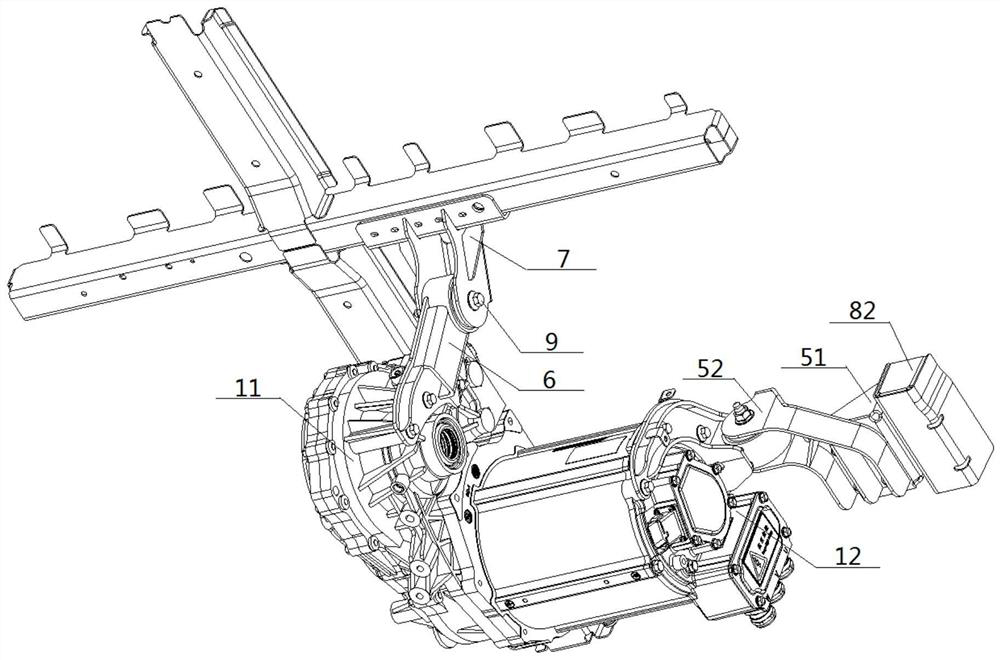

[0073] see figure 1 — Figure 18 , a rear rear drive system of an electric vehicle, comprising a power assembly 1 and a vehicle frame 8, the power assembly 1 includes a reduction box 11 and a drive motor 12, the right side of the front end of the reduction box 11 is connected to the drive motor 12 is connected to the left end, the two sides of the rear end of the reduction box 11 are respectively connected to the inner ends of the left drive shaft assembly 13 and the right drive shaft assembly 14, and the power assembly 1 is connected to the vehicle frame 8 through the suspension system ;

[0074] The suspension system includes a left suspension 2, a right suspension 4 and a rear suspension 6, the left side of the front end of the reduction box 11 is connected with the left suspension 2, and the junction of the left suspension 2 and...

Embodiment 2

[0078] Basic content is the same as embodiment 1, the difference is:

[0079] See Figure 19 , this figure is the pointed bolt 10 used when the present invention carries out the bolted connection, and it is also used as the pipe-through shaft 9 simultaneously. The pointed bolt 10 comprises a nut 101, a screw section 102, a threaded section 103, and a bolt head 104 connected in sequence, and the side wall of the threaded section 103 is provided with external threads, and the top of the bolt head 104 is connected to the threaded section. 103, the bottom end of the bolt head 104 extends outwards, and the diameter of the bolt head 104 is tapered from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com