Aviation composite part forming tool with blocking frame

A technology for forming tooling and blocking frame, which is applied in the field of forming tooling for aviation composite parts, which can solve problems such as unqualified parts size, and achieve the effects of reliable connection, not easy to damage, and flexible disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

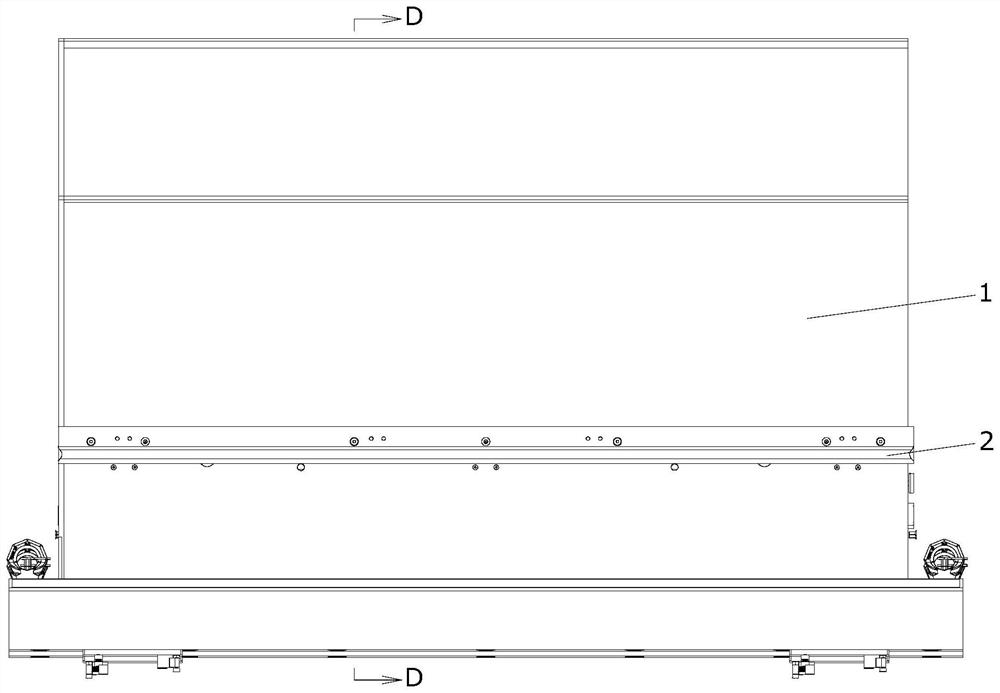

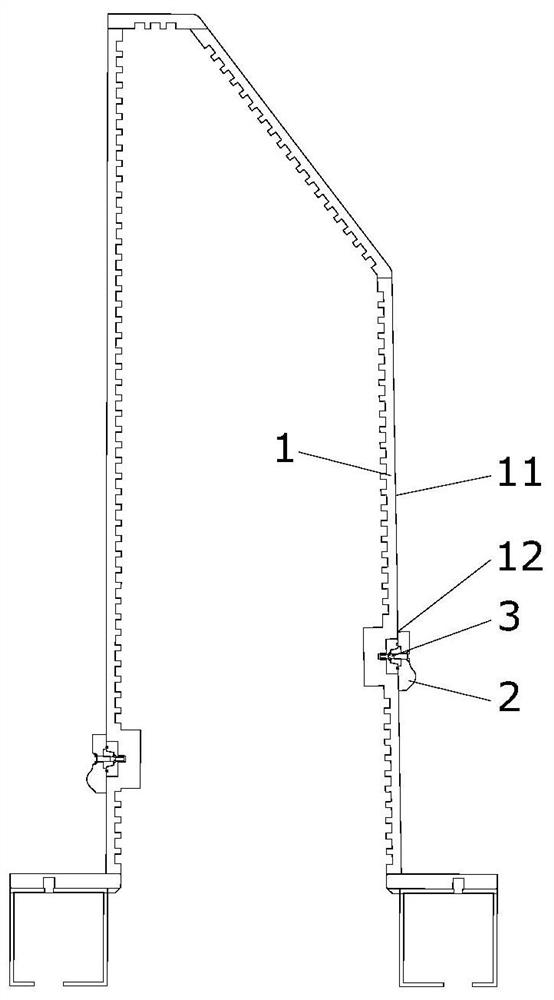

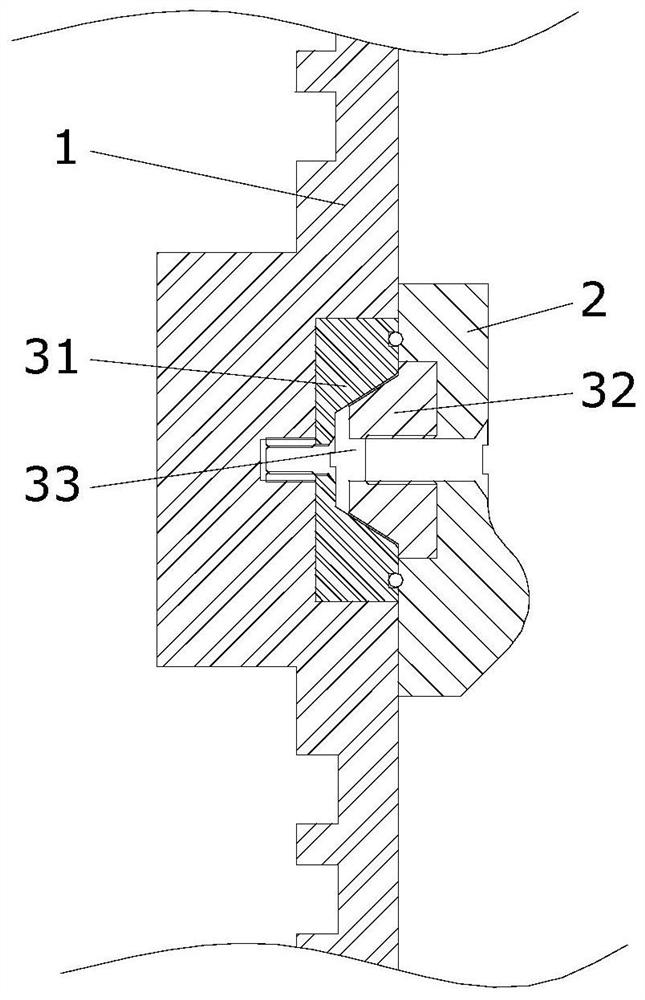

[0018] An aviation composite parts forming tooling with a retaining frame, as attached figure 1 , 2 As shown, it includes a tooling body 1 , a frame 2 , and a magnetic structure 3 .

[0019] The tooling body 1 has a depth and length, and a working surface 11 is arranged on its outer surface. The prepreg is laid on the working surface 11 , and the retaining frame 2 is a strip structure. The setting can be set continuously or at intervals. The magnetic attraction structure 3 is arranged between the block frame 2 and the tooling body 1 to connect the two. There can be multiple magnetic attraction structures 3, so that the block frame 2 is installed on the tooling body 1. The frame 2 supports the edge of the prepreg. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com