Automatic stud welding gun

A stud welding, automatic technology, applied in the direction of welding rod characteristics, welding equipment, welding accessories, etc., can solve the problems that the ceramic ring clamp cannot be opened, the structure of the stud welding torch is complicated, and it is difficult to adapt to the stud welding, and it is conducive to popularization The effect of application, high strength, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

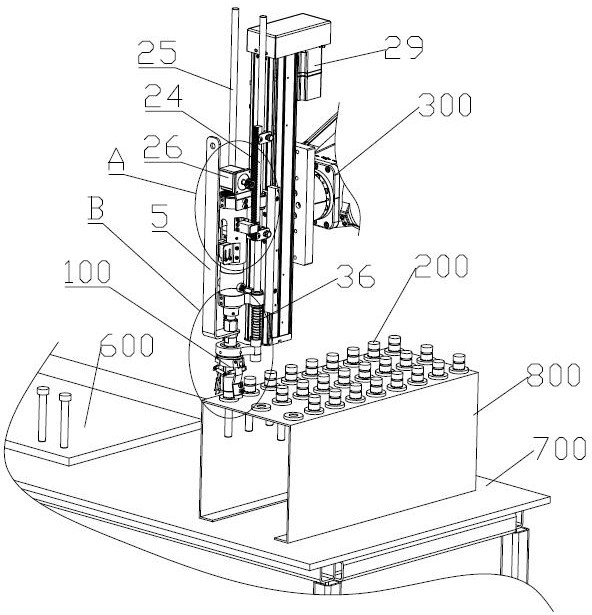

[0047] refer to Figure 1 to Figure 6 , automatic stud welding equipment, including automatic stud welding gun 100, robot 300, welding machine 400 and control cabinet 500, automatic stud welding gun 100 is installed on the manipulator of robot 300, the manipulator is a multi-degree-of-freedom manipulator, and the control cabinet 500 is electrically connected The welding machine 400, the automatic stud welding torch 100, and the robot 300 are electrically connected to the electric control box and the control cabinet 500 of the robot. The automatic stud welding torch 100 takes the welding stud 200 and the ceramic ring 201 on the decoration table 800, and sends the welding stud to the position above the weldment 600 of the workbench 700 through the manipulator, and welds the welding stud 200 through the automatic stud welding torch 100 on the weldment 600 (see below for details on the welding process).

[0048] refer to Figure 1 to Figure 22 , the automatic stud welding gun 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com