Open floor support plate forming equipment with electric control feeding mechanism

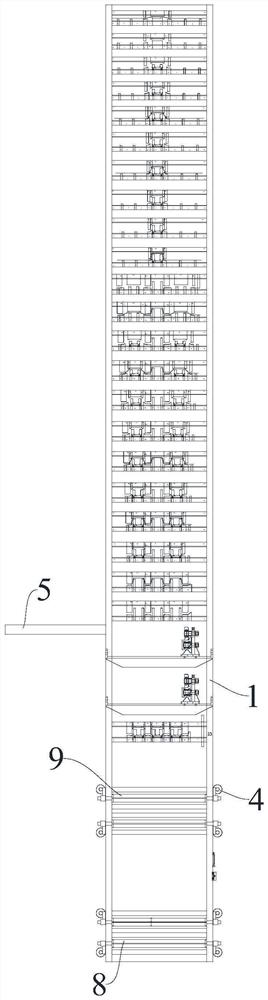

A technology of feeding mechanism and forming equipment, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of inability to freely adjust the height and number of conveying layers according to needs, inconvenient adjustment operation, and single scope of application. Achieve the effects of low maintenance and replacement costs, simple and convenient adjustment operations, and simple loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

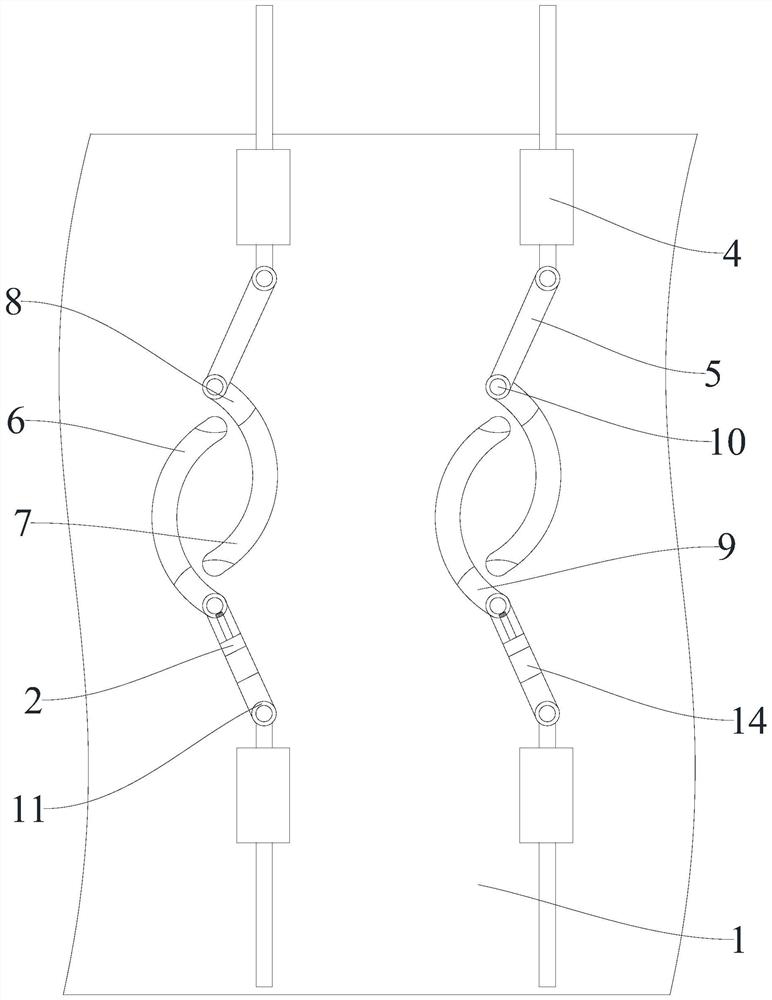

[0025] Example: People control the lifting and lowering of the electronically controlled hydraulic strut 4, and the electronically controlled hydraulic strut 4 drives the lateral link 12 to lift and turn, thereby using the linkage ring 11 to drive the lateral assembly shaft 10 to rise and fall, and the electric power at both ends of the lateral assembly shaft 10 Control hydraulic strut 4 linkage control, synchronous lifting. Because of the arc-shaped dislocation structure, the supporting roller shaft 8 and the driving roller shaft 9 can be lifted and lowered in a dislocation, and the minimum space layout is convenient for the two to switch positions.

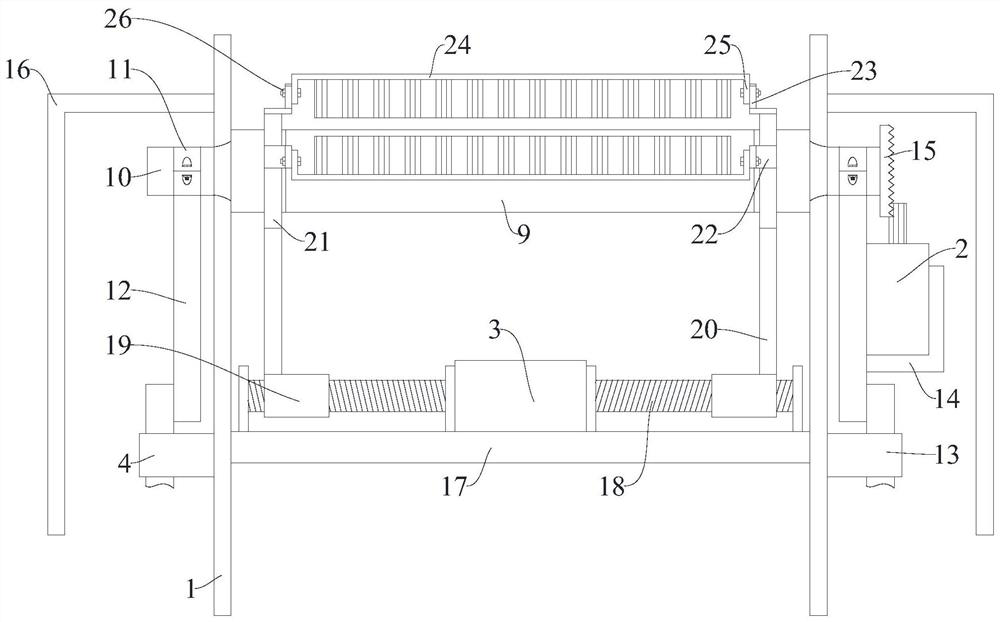

[0026] At the same time, the driving motor 2 drives the lateral assembly shaft 10 to rotate through rotation.

[0027] Further, in order to improve the guiding stability and facilitate the installation of the drive mechanism, the outer side of the molding machine body 1 is bolted with a side guide tube 13 for improving the stability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com