A reactor retrofit process for effecting reaction and filtration concentration

A reactor and filter technology, which is applied in the field of reactor modification for reaction and filtration concentration, can solve the problems of a large number of equipment and a large area of equipment, and achieve the effect of improving the efficiency of filtration concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

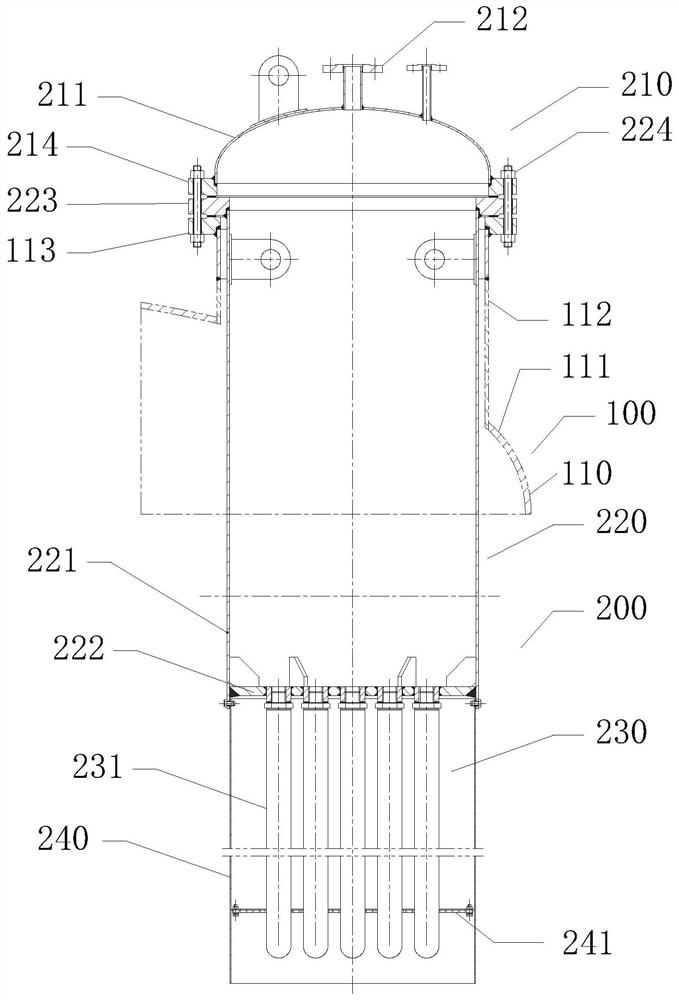

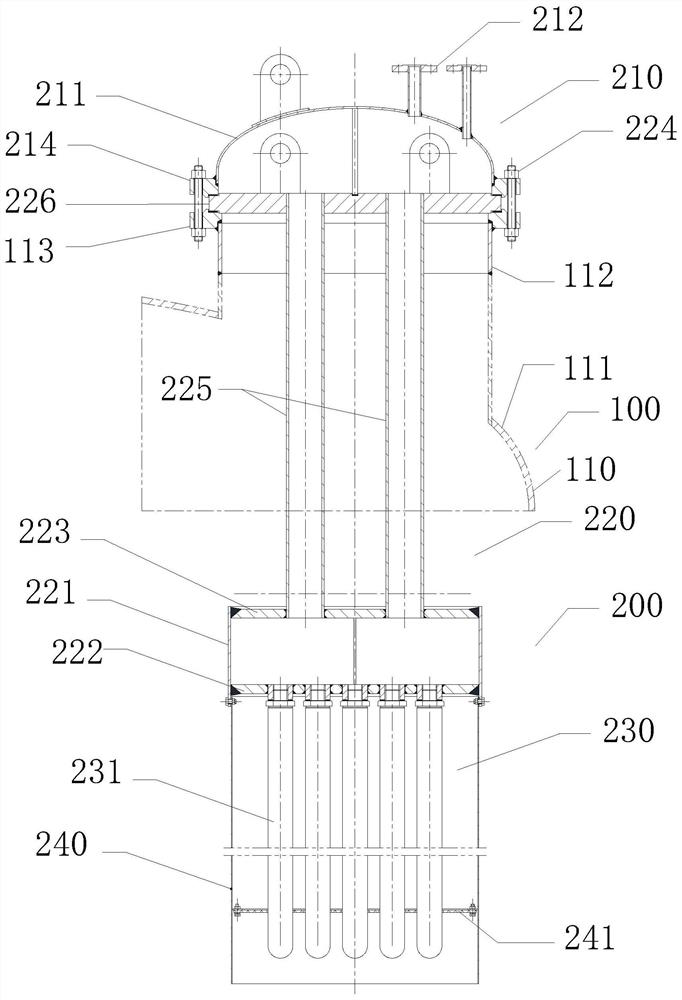

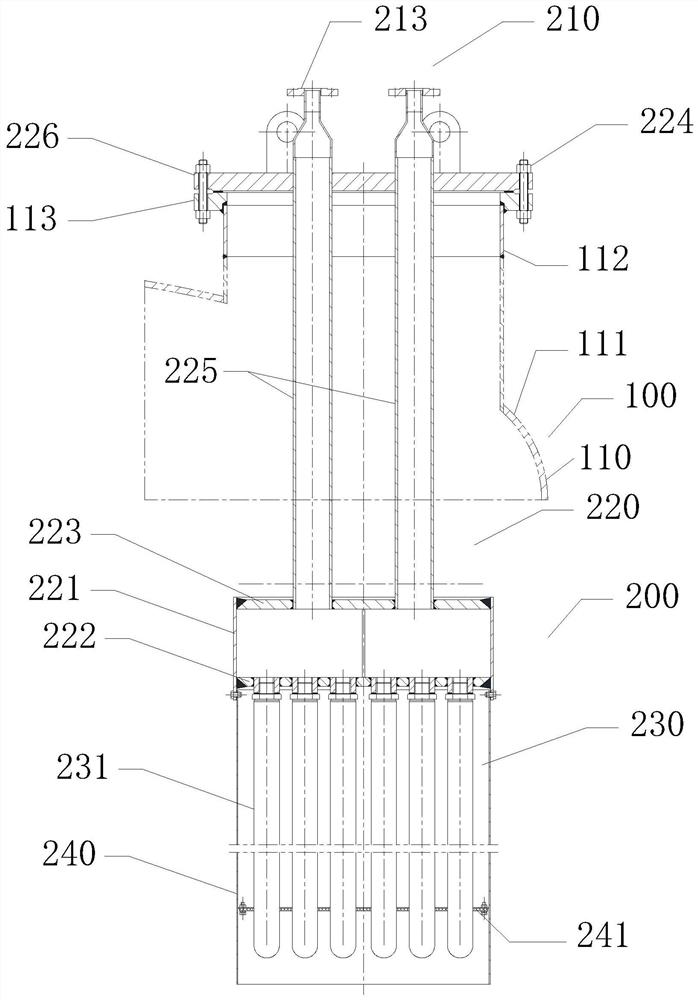

[0114] This embodiment adopts a method for preparing a positive electrode material precursor, including:

[0115] Provide to reactor 100 the raw material that comprises the metal salt solution that is used to prepare cathode material precursor; Prompt raw material reaction to generate cathode material precursor, and continue to provide to reactor 100 during the growth process of cathode material precursor to ensure the growth of cathode material precursor to said metal salt solution to set requirements;

[0116] The solution in the reactor 100 is subjected to solid-liquid separation and filtration by the filter element located in the reactor 100 so that the liquid amount in the reactor 100 is maintained in the range required for the reaction; when the positive electrode material precursor grows to the set requirement, Drain it. After the extracted solution is output from the net liquid output port 11 of the filter, it is subjected to gas-liquid separation.

[0117] By adopti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com